Why Anti-backlash gears are so important and what you can do wrong

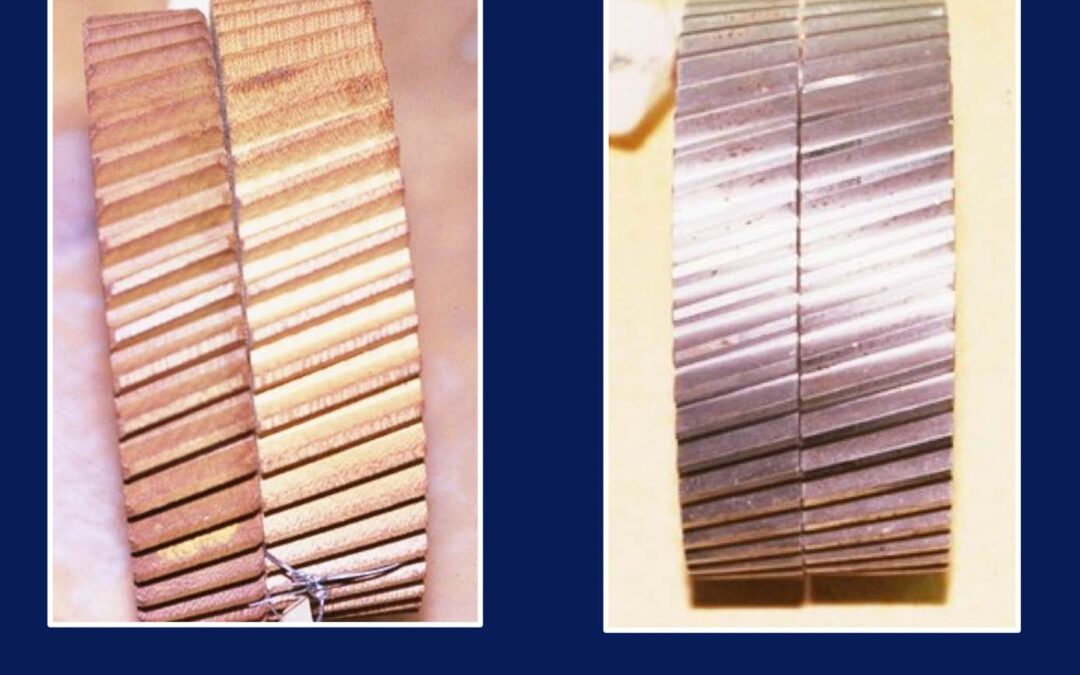

Anti-backlash gears

Anti-Reverse gears are the most important parts of an inking unit, not only is it the inking unit drive with the rubber roller and plate cylinder.

It also controls the printing pressure with the print, the main idea is to match the color.

Register and synchronize the 8 inkers at the same time.

Registering an image is very critical especially when the label has 8 colors to match and each plate has only a few dots of free space available before hitting the other plate.

The way the clearance is removed and held in place is controlled by 2 springs in the die.

As you can see in the image above, the image is blurred and not clear, this is because the Anti-backlash is too much and the 2 die springs cannot eliminate the backlash.

In the old days, speed and printing were not so critical, as they were only 4 colors and simple design.

But now the market has been changing and more and more customers are presenting their brand label with more colors (>4 colors) and a difficult design.

All these requirements are now met by the Anti-backlash gear, which drives the inking unit and keeps the image in the same position at any speed.

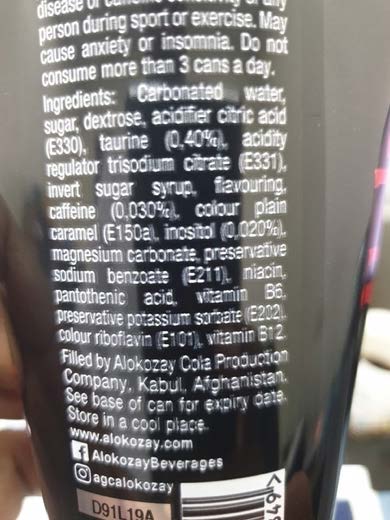

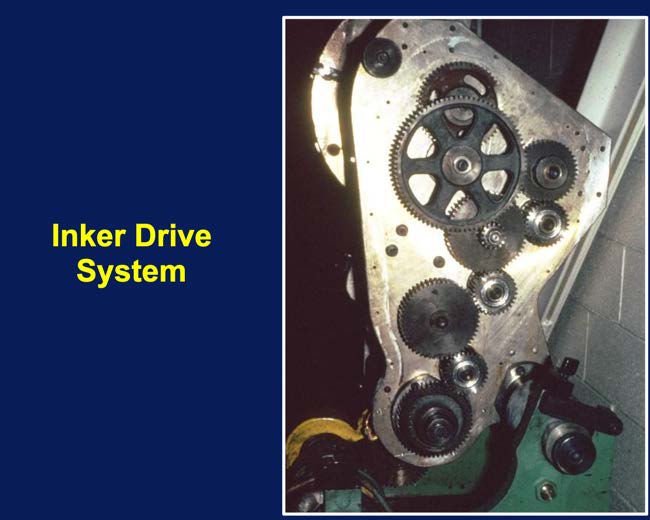

Inking unit drive system

Therefore, it is very critical to maintain this Anti-Reverse gearing very well to ensure

a pleasant and smooth production.

What can happen if the Anti-backlash gears are not in good condition or are incorrectly assembled with wrong parts?

Components purchased from different suppliers can cause problems due to

different machining tolerances. When the inking unit is rebuilt, is it made a

checking the teeth of the backlash gear to indicate that they are functioning properly. Use a Pitch 10 and DTI to check it. The gearing is set to an accuracy of 0.0005″.

So it is not good to have set gears running for 0.003 “.

What is the size of the ring support?

For first gears 5CD2-40-3 with brass bracket 5CD2-40-14

Bracket diameter 39.975″ – 39.973″.

The ring bearer for this is CD2-90-145. Diameter. 4.9975″ – 4.9965″

-Photo – Anti-backlash gear assembly, hub and carrier ring

For later models with the carrier ring as part of the gear casting it is: –

Gear 5CD4-40-2 Gear Diameter 39.750″ – 39.748″

6CD6-90-2 Backset Bracket Diameter 5.2225″ – 5.2215

The first model had a larger gear bracket and if the rear gear is engaged it is possible to over press the inker and damage the gears unless the larger backlash bracket is installed.

The brass backlash ring bracket can also be mounted differently.

Some are fastened with a large locking ring and others are bolted. You should check your own equipment to make sure that everything is correct and compatible.

Once you try to maintain this setting with your inker it should help and avoid any downtime.

If the adjustment is not started using what is recommended, these can lead to serious problems, such as damaging the gear.

This photo shows an incorrect hub being started to drive the inker, this hub has no support ring to protect the gear from excessive pressure.

Broken bolts inside the Backstop caused this damage and sheared the teeth of the

gearing.

With this backlash gear the image will move back and forth every time the machine is changing speed, as you can see, the gears are stuck together and cannot remove the backlash.

In case the support ring is badly adjusted it may hit the gear while running and after a while, due to the high pressure, the 4 bolts may break and damage the teeth.

This is the result of high pressure between the gear and the ring carrier.

The end result of all this is downtime and several parts that need to be replaced.

It is therefore important to follow the correct settings and keep the Anti-backlash gears in good condition.