How to get a correct rubberizing of a lid

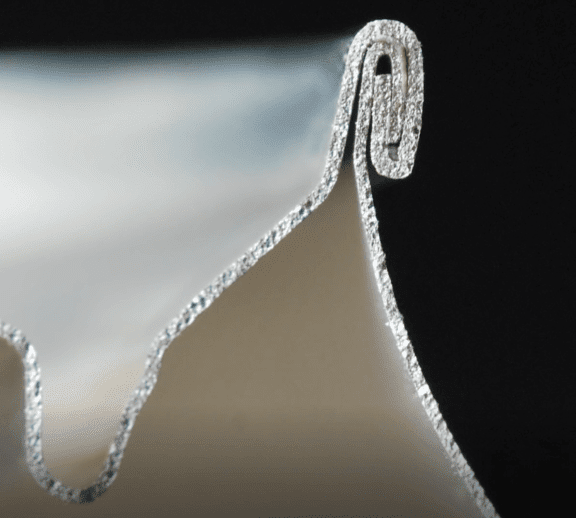

In order to achieve a correct rubberizing of a round cap, it is considered necessary that the cap is turned at least two full turns during the application of the rubber, with an overlap of about 5 to 10 mm between the end and the beginning of the rubberizing, depending on the diameters. This process must be controlled in order to correctly adjust the gumming process.

Gravimetric control can be carried out by octants, i.e. by 45° rubberized sections (joint octants), to ensure a uniform perimeter distribution of the rubber. On large diameter caps (153 or larger), consideration could be given to dividing the control into 16 22.5° sections.

It is important to weigh the gasket sections with high precision analytical balances, with an accuracy of at least 0.01 mg, although 0.1 mg may be sufficient. In addition, the flange of the lid should be opened completely, flattening the external flange, to visually check the overlapping area and the gumming.

If the speed of the gumming machine allows it, it can be gummed with more than two turns (3 or 4 turns) with an overlap of 1/8 of a turn to achieve a more homogeneous distribution of the gum around the cover.