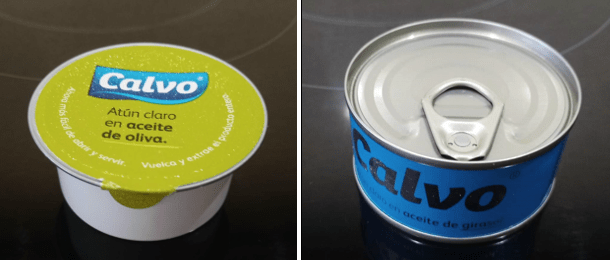

The canning company CALVO has put on the market a new packaging of tuna in oil that presents a new design of packaging and opening, which is presented as a great advantage for the consumer by the easy extraction of the packaged product (until now had to always use a covered) and also presents great technological advances in the field of metal packaging, which we try to outline in this article.

|

|

|

The packaging is still a “standard” format stuffed tuna pack, with an easy-open lid, of the type of heat-sealed aluminium film, which was introduced on the market more than 15 years ago. It has the advantage of being easier to open than the classic easy-open ring-top lid, and avoids the problems of difficulty in opening and breakage that in some cases usually occurred due to poor handling.

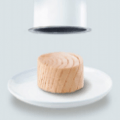

The great advantage comes because the container has NO LID, that is to say, the thermosealing is done on the container itself, which has been provided with a sufficiently wide flange, which allows the film to be thermosealed directly, which not only saves material, but also facilitates the closing, and it is presented as a safer container, since compared to the traditional one, only one closing operation is done, not two, as in the classic containers with thermosealed lids.

It also has the advantage that the inner coating is continuous up to the heat-sealed closure, which means that in no case can there be contact between the metallic material and the packaged product as could occur in previous heat-sealed closures.

|

|

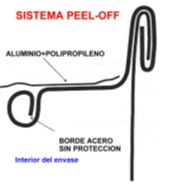

In the diagram in the figure above, we see both types of closure compared. As can be seen, the traditional heat-sealing system has two sealing points, the traditional heat-sealing and the traditional double sealing, whereas the Calvo packaging system, “Real Peel®“has only one sealing point, the thermosealing.

On the other hand, as we mentioned before, in the traditional heat-sealing system, there is the possibility that the packaged product comes into contact with the steel edge of the ring that holds the heat-sealed film, while in the new packaging system, the metal edge remains on the outside, with no possibility of contact with the product.

PACKAGING. –

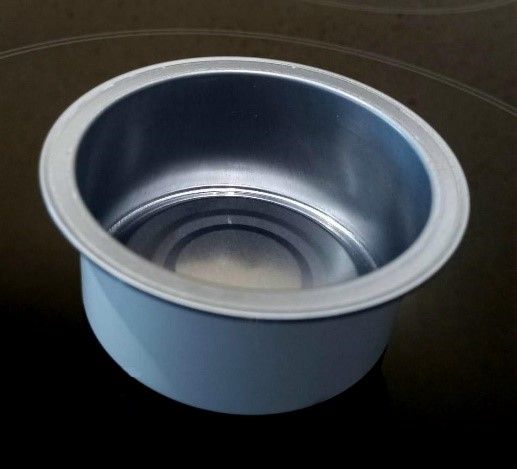

When technically analysing the container, we find a deep-drawn container, made in two operations, deep-drawn and re-drawn, which, instead of the classic flange to hold the lid in a double closure, has a flange with sufficient surface area to directly perform the heat-sealing. In this way, we save the lid component, which not only facilitates the process, but also means a great saving in material, being, therefore, more environmentally friendly.

Thus, the material savings of this packaging, compared to traditional packaging of the same format is as follows:

| FORMAT | CAPACITY | CONTAINER WEIGHT | % SAVING IN WEIGHT |

| CONTAINER 65 EASY-OPEN METAL | 85 ml | 24,2 gr | – – – |

| EASY OPEN PEEL OFF CONTAINER 65 | 86 ml | 19.5 gr | 19,4 % |

| CONTAINER 62 EASY DUMP BALD® | 82 ml | 14.74 gr | 39,1 % |

The container has a thickness of 0.22 mm and is made of laminated TFS (E.C.C.S.), with a thickness of 0.22 mm and a low elastic limit, in order to facilitate the drawing operations .

It has an internal diameter of 61.5 mm with a total width of 31.5 mm, which gives us a measured water capacity of 82 ml. The flange of the pack measures 6.1 mm, sufficient for heat sealing, which requires at least an effective width of 3 mm for proper sealing. Finally, the outer flange of the end of the container has a diameter of 1.5 mm and is made in such a way that the edge of the metal is well protected on the inside, so there is no risk of external corrosion, as there is no possibility of water accumulation inside the container.

|

|

|

The inner laminate is made of a colourless polypropylene, which is the material necessary to make the heat seal with the aluminium film, which is also coated on the inside with polypropylene.

The outside of the container has a white PET coating, which gives the container an impeccable sanitary appearance.

Both laminate coatings have an average thickness of 20 µmwhich makes them very resistant to friction and have a porosity of “0” which makes them chemically very resistant and inert in particular to this product which in general terms is not very chemically aggressive .

As we have already mentioned, the inner coating is continuous, so it could be a perfect container for other products with a higher aggressiveness, although, of course, the particular chemical resistance should be tested for other products.

Conservas Calvo, has put on the market a VERY advanced packaging, with an excellent quality and with a great vision of the future. Not only does it represent a great advantage for the final consumer, allowing the product to be easily removed, but it also presents a great saving in packaging material, with a great environmental benefit by significantly reducing the amount of metal used and therefore for subsequent recycling, with the consequent energy and emissions savings that this entails. Congratulations then, to the technical team of Calvo canned food, who have been able to put on the market a really innovative packaging with all the technical challenges that this means nowadays.

JOSE FCO. PEREZ GOMEZ

MUNDOLATAS Advisor

The package, using a dia 62 mm Easy dump BALD configuration (bowl shaped) does show really remarkable savings of 34,1 % in metal weight, compared to the standard EO 2 pc drawn can. One thing in my opinion still needs to be discussed: The use of a 0,22 mm thick ECCS substrate is still far away from the minimum gauge of say 0,17 mm, that technologically, at least for such round can, is necessary, to end up with a wrinkle – free body, done usually in a 2 stage drawing process. I would be curious to get explained, why no lighter gauge can material is used for this purpose of tuna packaging. The total savings compared to a rigid can could be subtantially higher than the 34,1 %, if 0,17 or 0,18 mm plate was used.