It is common in the metal industry that the case of having to move a facility already underway to another location is presented. This can happen for various reasons such as:

– By relocation of equipment within the same production workshop.

– By expansion of facilities in other ships

– By change of location of the factory.

– Etc.

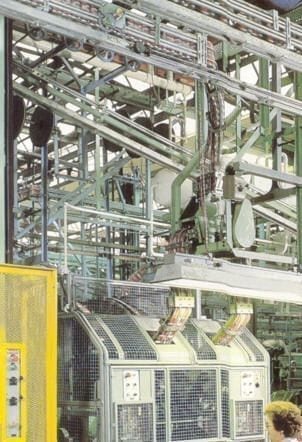

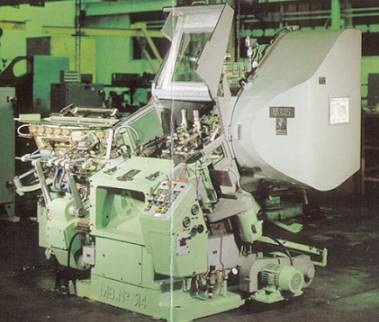

In all the previous cases, the measures to be taken are different depending on the complexity of the equipment to be moved. Not the same move from its initial operating position a press to a complete line of packaging manufacturing.

In the first case, the task is usually simple, because only one machine is affected, while in the second, machines, transportation systems, auxiliary equipment, etc. are involved. the work is much more complicated. We are going to focus on this last assumption because of its interest.

The tasks to perform must be classified in two very well differentiated stages. A prior to any movement of machinery and a final transfer itself. The final results will depend to a large extent on the efficiency with which the previous preparation is carried out.

The logical steps to follow are:

PREVIOUS PHASE

1º.- Formation of new human team

The first thing that it is advisable to do is to form a small team of people responsible for the operation, with a well-defined boss with full or priority dedication. If there are not enough people available, at least it is necessary to appoint a project coordinator with full powers and responsibilities.

The mobility of the human team is scarce and it is normal that with the change of place of an installation can not be accompanied by the usual mechanics and operators of it.

If this is the case, the next step is to prepare an adequate training of the new personnel that will take charge of the management of the equipment. As this may involve a long period of training it is desirable that this training be received on the installation in its initial location and as detailed as possible, so that they can collect the maximum experience through the old operators. This step is essential to shorten the start-up time of the equipment in its new location. It must be planned in detail and without hurry, without being stubborn in this phase since any expense will be widely recovered in the next stage.

2º.- Collection of information and study of it .

The second task is to collect all the possible documentation of the equipment that makes up the installation to be moved. This information collection must include:

– Manuals for installation, operation and maintenance of basic and auxiliary machines.

– Plans of the same

– General plans of the current complex installation that include:

– Well-defined current implementation

– Networks for the supply of electricity, gas, air, vacuum, etc.

If any of these documents is not available, you must make it before touching the current installation. As a minimum, it is necessary to create a sketch by hand as detailed as possible, including measurements, distances between machines, supply points, etc … It is also very useful to make a good number of general and detailed photos of the entire installation. The assemblers will thank you very much later. A detail photo is sometimes more effective than the best of the plans.

3º.- Determination of consumption and specific needs

The previous documentation must be studied thoroughly, determining the needs that the line has implied, such as:

– Foundations or special anchors.

– Characteristics of the soil (resistance to load or aggressiveness of products used in normal operation)

– Total and specific consumption of force and fluids

– Auxiliary equipment needs that are sometimes shared with other facilities and that can not always be moved with the main equipment

– Specific means such as: structures, stairs, chimneys, ducts, platforms, etc.

All this must be defined and ready to be launched at the time (purchase, construction, etc.). It is convenient in all cases to calculate the time necessary for its realization and its cost.

4º.- Study of space and environment in the new location

It is time to study in detail the characteristics of the ship and its surroundings where the new installation will be made. Among others, we must take into account:

– Free space available.

– Characteristics (free height, obstacles, columns, etc.)

– Soil: resistance, properties, ..

– Roof structure (resistance to possible loads, interferences with conduits, network support …)

– Basic supply networks: Situation, power and available flows, …

The data prepared in section 3 will be compared with those obtained here and it will be determined if they fit properly or on the contrary it is necessary to take some type of corrective action, such as: expanding the force transformation center, increasing the installed air capacity compressed, mount some complementary metal structure, reinforce part of the hearth …

Once all the needs have been defined, they will be documented and ready for launch, including an estimate of the time of completion and its cost.

5th.- Definition of a new implementation plan

With the available data of the equipment and the new enclosure, now the new implementation can be defined. The following plans will be designed:

– General of the installation

– Detailed supply networks

– Foundations

– Electrical pictures and others

– Chimneys, ducts, supports, specific structures, etc.

– Of detail in the points that are required

Once again, a new task will be defined and listed with the corresponding time and cost.

6º.- Development of a PERT

It is now necessary to list all the tasks to be carried out until the completion of the work and that until now have not been studied: disassembly, transport, assembly … and make an estimate of the resources needed to complete them: labor, time, materials , cost…

An important factor is to know the human resources needed in each of the phases to organize their availability. It may happen that sufficient human resources are not available and their outsourcing is required. In this case it is one more factor to evaluate and include in the list of tasks.

We already have a detailed view of all the work to be done throughout the process. Now it is necessary to order them and start them in the right sequence of time so that everyone is ready at the precise moment. For that, nothing better than developing a Pert that includes each of them.

PERT is basically a method to analyze the tasks involved in completing a given project, especially the time to complete each task, and identify the minimum time necessary to complete the total project. We will not go into the detail of how a PERT mesh is made, as it is a well-known technique. If someone wants to expand their knowledge you can find information on the Internet.

This PERT mesh is an excellent tool to have an overview of all the tasks to be carried out, making it possible to know when each of them has to start so that it is ready at the right time without stopping the realization of the others. If the number of tasks is small, it may not be necessary to apply this technique and a sequential ordered list of them would suffice.

It is also the time to close the budget of the operation, making a summary of foreseeable expenses from the assessments that have been made in each of the previous steps

7º.- Launch of supplies and previous works

With the PERT in front as a guide, we can now launch each of the tasks: purchase of equipment and materials, construction of elements, contracting services …. in the appropriate dates so that its completion fits in the foreseen.

8º.- Assemblies of services and auxiliary installations

The first assemblies to perform are all related to auxiliary facilities, such as:

– Basic networks of water, gas, air, vacuum, …, leaving slopes down to the connection points

– Electric network, except all current boxes

– Special supports to the roof or fixed to the ground, that serve as support to transport systems, aerial equipment, etc.

– Soil preparation: anchor holes, reinforcements of the floor, surface protections …

It is time to start them, so that they are ready before the arrival of the machinery.

9º.- Hiring of special transport and insurance

Finally before starting the disassembly of equipment, it is convenient to hire the means of transport to the new location, taking into account:

– Need for special means, such as trucks with a reduced platform, specific tonnage or length, all depending on the dimensions and weight of the machines to be transported.

– Traffic permits or others if required.

– Insurance policy that covers the operation.

– Load calendar.

TRANSFER PHASE

Before starting this phase, the first thing that must be assured is that the needs of the clients are assured during the duration of this operation. For this, it is required that according to Commercial a security stock be created for the product that this facility manufactures or dispose of another that is capable of supplying unemployment.

1º.- Disassembly

The time has come to begin the task of transfer itself. The first operation is to dismantle the entire installation from its original location. It is necessary to have a team of mixed personnel (mechanics and electricians) who proceed simultaneously in this work. If it is necessary to resort to outsourcing of personnel, it is better to hire a company specialized in assemblies or to form mixed teams of own personnel with external personnel. It is desirable that the same personnel carry out the disassembly as well as in the new assembly, this will make the work much easier.

It is necessary to mark properly all the elements, especially the wiring and electrical panels to avoid errors in the subsequent assembly of the same. It is also convenient to mark the specific positions of the mechanical components. From all this, lists and delivery notes will be prepared for each of the shipments for the purposes of control of the operation and of the insurance company.

2nd.- Assembly

With the arrival of the equipment to the new site, the assembly operation begins. The final results will depend on the main tasks and their good execution.

It is difficult to give in a few lines enough criteria for a good performance of this work. Only by way of example can we mention:

– Start with the basic machine of the installation. All the others will be joined to it.

– Pay special attention to the foundation, anchoring and leveling of the equipment.

– Use quality means Something is being done for a long time.

We have already indicated that the human team must be the same one that carried out the dismantling. In case of resorting to external means it is better to dedicate these to electrical or mechanical installations of not much responsibility, nobody like the mechanics of the house to give priority and importance to the basic points.

3º.- Tests and putting point

When the assembly is finished, you enter a delicate phase. The management thinks that the operation has been finished and begins to demand production, since the time used in the previous tasks, if an adequate stock has not been planned, leads to stock market shortages and nerves begin to emerge. But it usually happens that we enter a period of time of difficult estimation where the equipment does not work well. It is the stage of testing and tuning.

Sometimes it will amaze us that teams that have never generated difficulties, now decide not to “go”. It is necessary to make a fine adjustment of all of them, starting from scratch. This is logical because during transport many of them have become out of tune. In addition, the elements between machines (conveyors, elevators, falls, etc …) can also present problems. It is an excellent time for the new staff to gain experience. A good help is to have the old staff to temporarily help in this operation. Your expertise will shorten this phase.

In any case it is normal that during a certain period of time, the performances of the equipment are below the usual in the previous location. There is a learning curve and point setting that interests you to have a rapid positive evolution but that is necessary to assume.

4º.- Homologation of the product

As a final point to this process, it only remains to verify that the quality of the manufactured product meets the appropriate levels. This can be a work only internally or that also involves the supplier. It may happen that the latter must approve the article produced in the new implementation of the equipment.

FINAL NOTE: The foregoing may be for the most part applicable to the assembly of a new installation.

0 Comments