En otro artículo publicado en esta Web se ha descrito de forma extensa la historia del envase metálico. Ahora pretendemos resumir en poca líneas la misma, para aquellos que la puedan necesitar como introducción de otros trabajos ligados a esta industria.

HISTORIA BREVE

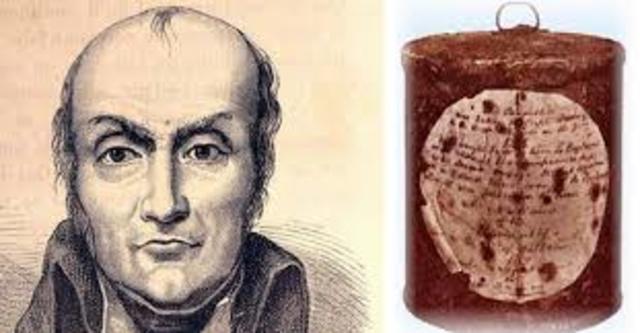

Inglaterra en los inicios del siglo XIX está viviendo un desarrollo que da a su industria un impulso que le asegura la hegemonía económica mundial. En Londres se conocía los adelantos que en la conservación de alimentos suponía el método ideado por el francés Nicolás Appert, consistente en calentar a 100 º C los mismos en botellas con cierre hermético. Peter Durand estudia el asunto y constata que es fundamental un buen diseño de los recipientes empleados en esta labor.

En 1.810 presenta una patente que permite “preservar alimentos en vasos de hojalata u otros metales”. En ella explica en que consiste este vaso, se trata de un cilindro cerrado por ambos extremos en el que sus piezas se unen por soldadura. Durand se da cuenta de las ventajas que representa este material: Ligereza, irompibilidad, conductibilidad del calor… Así se convierte en el padre del envase metálico.

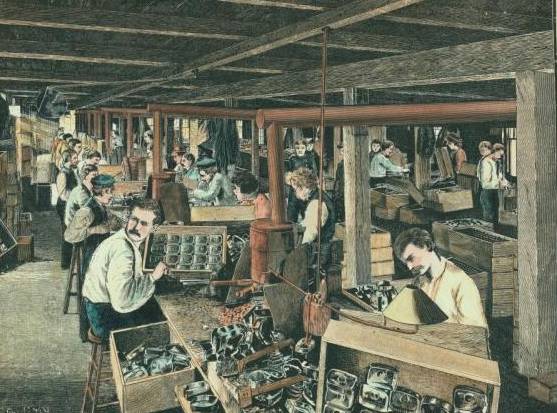

Durand no llegó a hacer latas ni envasados. Fueron los ingleses Bryan Donkin y John Hall, quienes usando la patente, empezaron a realizar pruebas y después de un año montaron un taller de conservas. Pronto dispusieron de un grupo de artesanos que eran capaces de hacer hasta 60 latas por día en una labor totalmente manual. En pocos años esta industria se extendió por Europa y America del Norte. Fue esta última quien pronto se convirtió en la locomotora de este sector, aportando múltiples innovaciones. Los desarrollos se fueron escalonando en el tiempo: De procesos manuales a automáticos, de bajas cadencias a elevadas velocidades. Hoy se llega a montar instalaciones capaces de fabricar hasta las 2500 por minuto. Nuevos productos mantenían el dinamismo del mercado: aerosoles, fácil apertura, botes para bebidas… y un largo etc. La técnica es un gran bien al servicio del hombre.

0 Comments