SUMMARY

It is important to have a good document on the basic matter in the metal sector, tinplate, TFS, aluminum … It is useful for a multitude of tasks. The following describes how to prepare the same, incorporating various data from multiple applications.

SPECIFICATIONS OF MATERIALS

In the metal industry it is convenient to have a document where all the data related to the metal to be used in the manufacture of each product are reflected. Said document is designated with the name of “Tin Specification”, in the case that the material is tinplate, although it can also be TFS, aluminum or black plate.

This document has many applications such as:

– Technical office

– Base document to define the order of raw materials by the Purchasing Department.

– Calculation of costs.

– Base document in the coil cutting operation.

– Preparation of photoliths by the corresponding Study.

– Preparation of printing plates and rollers for lithography.

– Production: Base document for the adjustment of equipment: Scroll, presses, shears …

– Quality control, for verification of records and cuts.

– Etc.

SPECIFICATION OF TAPAS TIN

We are going to focus on this work in the form of preparing a metal specification for tapas. Well in the easy opening version or classic flat top, the document in both cases is similar. We will see what data are the most convenient to include in it and how each one is calculated.

To follow the procedure better we will do it taking a practical example, in our case it will be the standard bottom for preserves diameter 73 mm, which is one of the most used in the metal industry.

The first data that must be known is the cut, that is to say the diameter of the disk necessary to die to form the bottom. For this background it is 88.7 mm. With it we can calculate the dimensions – width and length – of the sheet drawn from a coil. We will not enter into this calculation, since he himself is well detailed in a work already published on this Web. Watch:

Calculation of the profile of a zigzag cut (cut in “scroll”)

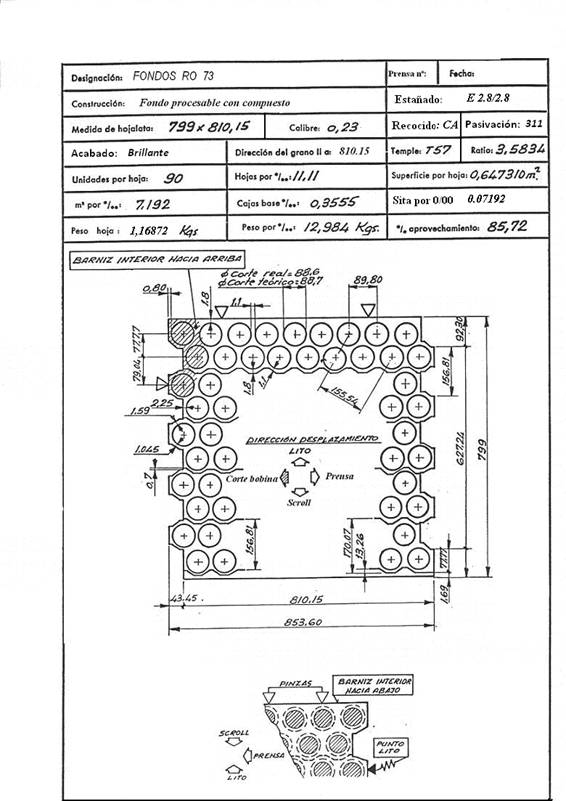

Once the dimensions of the sheet are known, you can start making the spec sheet, drawing the sheet and detailing all the dimensions that define its geometric composition. See figure # 1. As you can see, this sheet has two parts. A first superior, with a series of boxes where the data that we are calculating will be reflected, and the lower one that will present the drawing of the sheet with all its data.

The first four boxes are purely informative and they specify:

– Commercial designation of the fund

– No. of press that will manufacture it, if applicable.

– Date of completion of this document

– Basic characteristics of the construction of the fund.

Figure nº 1: Specification of bottom tinplate 73

Then we enter the definition of the sheet of material to be used. To determine the dimensions of width and length of it, we must take into account a number of factors that the size of the sheet must meet, the main ones are:

– Tin price of purchase price, so as not to incur extra costs for dimensions. We must ensure that they adapt to the minimum rate for measures.

– Maximum and minimum dimensional capacity of the coil cutting line. They must be within this capacity

– To be included between the maximum and minimum dimensions allowed by the varnishing and printing lines.

– Dimensional capacities of the second cut scroll, that is, for cutting strips, and the press store. The resulting strips of the sheet should be within its range.

From the analysis of all this, and the corresponding calculation following the work mentioned above, there will be some valid sheet dimensions to be used during the process without problems. The net length of the blade coincides with the advance step in the cutting line, this is the data necessary for the calculation of material consumption, the gross length includes the height of “crenellated” (43.45 mm in our example) and must take into account for the dimensional limitations of the equipment.

Once the coil width is known, the rolling direction of the base steel, ie the direction of the grain, is automatically set.

Depending on the dimensions of the bottom, its mechanical resistance and its use, we will be given another set of data such as:

– Tin coating

– Thickness

– Annealing

– Passivation

– Surface finish

– Quenching

We do not stop to delve into these parameters because they are well known, and if required you can consult the works of this Web:

All these values must be written down on the corresponding boxes of the fund specification sheet 73.

We now enter into the determination of a series of interesting data, valid for later calculations in other phases of the process.

– Units per sheet: Indicates the number of funds obtained per sheet, 90 funds in our example.

– Sheets per% 0 : Shows the number of sheets needed to make a thousand funds. It is obtained by dividing 1000 by the number of units per sheet. (1000/90 = 11.11)

Both data are interesting to calculate the number of precise sheets to cover a certain order of funds.

– Surface per sheet: It gives us in m2 the area of the sheet. It is obtained by the product of the net length (cutting line pitch) by the roll width expressed in m. (0.799 x 0.81015 = 0.647310 m2).

– Ratio: Indicates the size ratio between the surface of the sheet and that of the sheet taken as a unit in the tinplate market, which is a sheet of dimensions 20 “x 14” (508 x 355.5 mm = 180594 mm2 = 0.180594 m2 ).

Ratio = 0.647310/0.180594 = 3 .5843.

– m2 per% 0 : Necessary surface of tinplate to make 1000 funds. It is the product of the surface per leaf per leaves per% 0 . (0.647310 x 11.11 = 7.192 m2)

– Base box by% 0 : Before determining this data, we will define what is “base box”. It is a unit of measurement widely used in the tinplate market. It is a multiple of the unit sheet (20 “x 14”). There are two types of “base box”:

- American base box : Tinplate media unit per surface. It is equal to the surface of 112 sheets of dimensions 20X14 inches or what is the same, 31,360 square inches and equivalent to 20.23 square meters. It is used mostly in the American market. 1 base box = 1.1201 European base box = 0.2023 places

: Tinplate media unit per surface. It is equal to the surface of 112 sheets of dimensions 20X14 inches or what is the same, 31,360 square inches and equivalent to 20.23 square meters. It is used mostly in the American market. 1 base box = 1.1201 European base box = 0.2023 places - -European base box: Tinplate media unit per surface. It is equal to the surface of 100 sheets of dimensions 20X14 inches or what is the same, 28,000 square inches and equivalent to 18.06 square meters. It is used preferably in the European market. 1 European base box = 0.8928 base box = 0.1806 places

Therefore the data ” base box per% 0 ” reflects the base boxes needed for tinplate to make 1000 funds. It is determined by dividing the surface m2 by% 0 by the surface of the base box. According to the American or the European would be used:

American base box by% 0 : 7.192 / 20.23 = 0.3555

European base box by% 0 : 7.192 / 18.06 = 0.3982

– Sita by% 0: It is another way of expressing the same previous data. The SITA is another unit of measurement per surface of the tinplate and is defined:

– SITA: Tinplate measurement unit per surface, equal to 100 square meters (International System Timplate Area). Equivalent to 4,943 base boxes or 5,537 European base boxes

Therefore, “per% 0 ” is the number of sites needed to make 1,000 funds and is calculated by dividing the surface m2 by% 0 by the surface of a site. (7.192 / 100 = 0.07192 sitas)

All this data obtained: Surface per sheet, ratio, m2 per% 0, base box per% 0, and per% 0 , have several utilities, among others:

– Calculation of the cost of a tin order to the steel industry, the rates according to the country of origin of the merchandise, can use any of these units.

– Calculation of the cost of an order of lithography or varnishing of sheets. When you use third parties to perform this work, your rates also use these units.

– Internal consumption calculations.

– Weight per sheet: It is determined from the volume of a sheet by the density of the steel. Expressed in Kg. Would be:

Weight per sheet = (64,731 x 0.23 / 100) x 7.85 = 1,16872 Kg

– Weight by% 0 : Is the weight of tinplate needed to make 1000 funds. The equal to the weight per sheet multiplied by the leaves by% 0.

Peso por %0 = 1,16872 x 11.11 = 12,9844 Kg

These last two data are useful for:

– Calculation of the transport price.

– With certain suppliers, for the calculation of the price of the material.

–% profit: It informs of the net percentage of metal used to manufacture the funds.

% utilization = area of the cutting disc x number of cuts x 100 / surface per sheet.

% profit = 44.3 x 44.3 x 3.1416 x 90 x 100/647310 = 85.72%

This information is necessary for the calculation of the standard cost of the fund.

Once all these values are reflected on their corresponding boxes, we will have finished the specification sheet of the fund.

It could add other data depending on the particular needs of each one, such as: tinplate lubrication, internal code of this material, etc.

0 Comments