El material usado en un envase metálico se selecciona de manera que sea compatible con el producto que va a contener. Las características de los diferentes productos envasados en botes de metal son muy variadas, y cada uno de ellos tiene sus propias peculiaridades. De ahí que la elección de las materias primas para la fabricación de envases, debe de tener por fin dar al recipiente las mejores calidades de resistencia frente al producto. Inversamente, el recipiente puede tener también un efecto negativo en el producto, si los materiales no fuesen los idóneos para impedir las interacciones entre producto y recipiente.

ACIDEZ RELATIVA (pH)

Uno de los primeros factores a tener en cuenta del producto es el “pH”, o la acidez relativa del mismo. El producto puede ser demasiado ácido como la naranja o el limón, o muy alcalino como las lejías y los limpiadores, o tener un pH intermedio entre estos valores extremos. Dependiendo del grado de acidez o alcalinidad, el recipiente puede requerir diferentes tipos de recubrimientos interiores de barniz, para evitar un ataque químico del envase.

COLOR DEL PRODUCTO

El color del producto puede ser oto factor importante a considerar. Por ejemplo, si el color es un rojo o un azul profundo, se requerirá un barniz que actúe como cortina o barrera, para evitar que el estaño de la hojalata decolore el color natural del pigmento del producto envasado. Frutas de un color más ligero tales como manzanas, peras, etc. conservan su tonalidad, aun cuando el cuerpo del recipiente no esté barnizado por su interior. Ciertos productos encuadrados en la categoría de baja acidez, tales como verduras, carne y pescado, que están sometidos a un tratamiento térmico para preservarlos y esterilizarlos comercialmente, requieren un recubrimiento especial interior denominado del tipo “C”, para impedir la aparición de manchas obscuras de sulfuro en el envase y en el mismo producto.

CLASIFICACIÓN DE PRODUCTOS

Los productos que se envasan en botes metálicos se clasifican a la hora que definir el envase en dos grandes grupos: alimenticios – o alimentarios – y no alimenticios. Los productos alimenticios se clasifican a su vez en procesados y no procesados. El proceso supone someter el producto a un tratamiento térmico inmediatamente después del llenado y cerrado del envase, para destruir los microorganismos que ocasionan la descomposición. Los alimentos envasados procesados se pueden cerrar bajo un ambiente atmosférico, de vapor o de vacío. Los alimentos no procesados se pueden cerrar bajo condiciones atmosféricas, de vacío, o con gas.

Los no alimenticios son productos no comestibles que se embalan sin proceso de calor, y se pueden cerrar bajo cualquiera de las condiciones anteriores, dependiendo de sus características.

Alimentos procesados

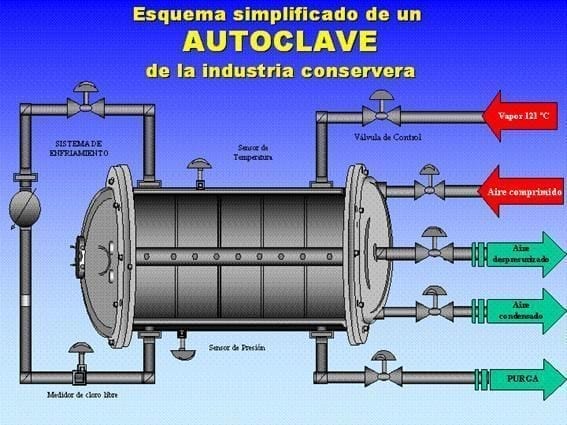

Los alimentos procesados no solamente requieren que el envase sea perfectamente hermético, para mantener el producto estéril e intacto después del tratamiento térmico, sino que también se precisa que el recipiente sea lo suficientemente fuerte y rígido para resistir la presión interna generada durante el proceso de esterilización.

La operación de “envasar” un producto alimenticio perecedero implica aplicar un tratamiento de esterilización por calor al mismo. Los envases empleados para ello son mayoritariamente cilíndricos y reciben el nombre genérico de “envases sanitarios”. Los ejemplos de productos más comunes envasados como alimentos procesados son las frutas, verduras, legumbres, carnes, pescados, lácteos, etc.…

Alimentos no procesados

Los mismos no requieren un proceso de calor para esterilizarlos y “mantenerlos”, aunque pueden estar sometidos a algún deterioro por la acción de factores como el tiempo, la temperatura….Estos alimentos son relativamente estables, y pueden ser resistentes al deterioro ocasionado por los microorganismos y enzimas. Para diferenciarlos con los productos procesados, se les suele designar como productos “empacados” y no “envasados”. Los envases que usan no requieren soportar altas presiones internas, y comúnmente se les clasifican como envases de “líneas generales”, que abarcan una variedad de formas y medidas muy diversas. Ejemplos de alimentos no procesados son: frutos secos, café, aceites comestibles, pastas y galletas, mantequilla, etc.

No alimenticios

Los no alimenticios son generalmente productos para el hogar, automotriz, agricultura, e industriales, empacados generalmente en envases no herméticos que no requieren esterilización. Para su conservación se usan envases de líneas generales que tienen diversas formas, medidas y características. Se diferencian en función de su destino, por la manera de apertura, vaciado, forma de trasporte, posibilidad de ser cerrados de nuevo cuando su utilización es parcial, etc.

Ejemplos de productos no alimenticios empacados en muy diversas formas son entre otros: pinturas, adhesivos, productos para el automóvil, cosmética, insecticidas, medicinas, productos químicos, grasas, tintas y barnices.

PRODUCTOS ESTÁNDARES Y FORMULADOS

Otra manera de clasificar los productos son dividirlos en tres grandes grupos: estándar, estándar formulados y formulados.

Los productos estándar son consistentes o uniformes en su forma y contenido de manera universal, y por lo tanto son bastante estables en los requerimientos del recipiente que los ha de contener. Se pueden considerar como productos estándar los alimentos naturales.

Los productos formulados son mezcla o mixturas tales como las salsas, que pueden tener diferentes ingredientes en proporciones variadas en cada caso y de acuerdo a una formula particular.

Los productos estándar formulados son una combinación de un producto estándar y otro formulado como por ejemplo “atún en salsa”. Los productos formulados son una preocupación para el proveedor de envases, ya que unas pequeñas diferencias en la formulación de los contenidos o un cambio de proveedor de alguno de los ingredientes, puede ser causa de alteración de las especificaciones requeridas del envase para un producto dado.

OTROS REQUERIMIENTOS

Los envases están diseñados no solo para tomar en consideración las caracteristicaza del producto, sino también los reglamentos y disposiciones gubernamentales de cada país, los diferentes métodos de esterilización, las condiciones de almacenamiento y manejo y las elevadas velocidades de producción.

El recipiente ideal es aquel que es lo suficientemente fuerte para proteger sus contenidos en su vida útil, además de ligero y resistente, lo más simple posible de fabricar en formas y medidas deseadas, hermético al aire ay al agua, agradable en apariencia, fácil de abrir, económico… Los envases sanitarios además deberán ser capaces de resistir las presiones y temperaturas del proceso. Como regla de oro el envase siempre debe satisfacer las necesidades del producto a contener.

Los fabricantes de envases suelen disponer de listados de donde se relacionan, en función del producto a contener, las características del envase adecuado: espesor de metal, recubrimiento mínimo de estaño, barnices interiores, compuesto… También influye el perfil de tapa/fondo empleado y el tipo de acordonado del cuerpo. A lo cual se puede añadir una serie de complementos en función de su utilización, como son forma de apertura, asa, gollete, llave…Estos listados son frutos de envasados experimentales en laboratorio corroborados por la experiencia durante años de actividad.

Todos los materiales están sujetos a cierto grado de deterioro y ataque durante el servicio que realizan a lo largo de un periodo de tiempo, la idea básica es construir un envase de duración razonable mediante la selección correcta de los materiales, la cual debe cubrir holgadamente las disposiciones legales sobre la vida útil de las conservas.

0 Comments