One of the main reasons that cause a bad placement of the varnish on the sheets is the lack of alignment or rotation of the sheets when they come out of the rollers of the varnishing machine. To prevent this from happening, you must ensure that the blades are always properly aligned by measuring them.

Innosen has found the solution to prevent this problem. Innosen, who have been in the metal packaging industry for over 20 years, are specialists in the development of sensors and quality control equipment.

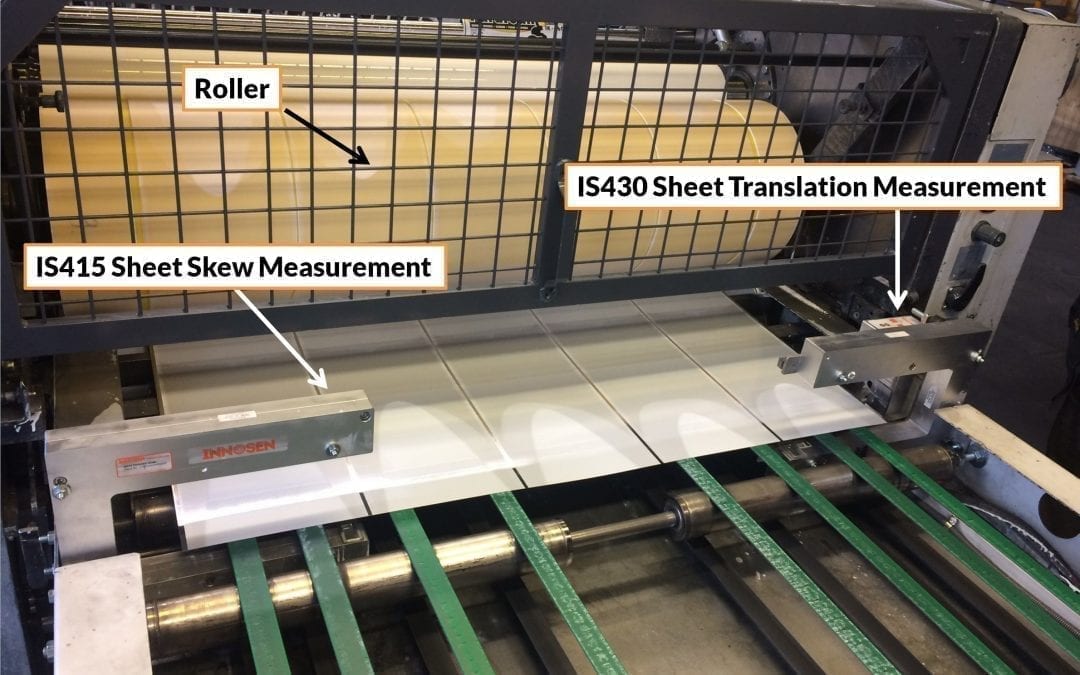

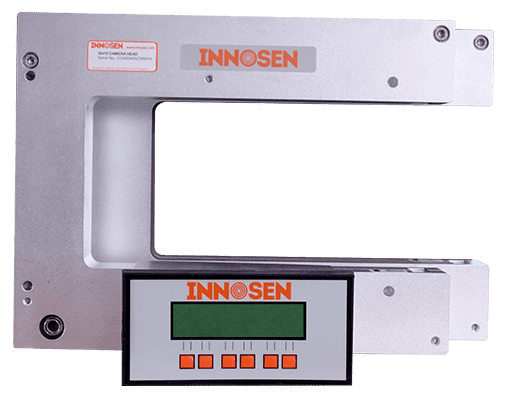

The IS415 Sheet Parallelism Control System reliably measures the alignment of the sheets on the coating and lithography lines and detects all misaligned or poorly aligned sheets. Due to the instantaneous detection, these films can be rejected, avoiding the problem of the application of the displaced varnish.

Using the IS415 can also improve the overall coating process, as it stores the statistical data of all measurements taken, allowing the user to make the necessary adjustments and improvements to the process.

Users have reported an overall increase in production of up to 8%. Simply increase the line speed and make sure that the statistics data remains acceptable! In addition, because the system inspects all blades 100%, it will ensure that all stray blades are detected, regardless of line speed.

You can see a video of the Innosen IS415 system here:

https://www.youtube.com/watch?v=y5NTUMmjLdY

And learn more about the system here:

To learn more about our products visit our website: www.innosen.com