Use, types and design of these accessories for metal containers.

USE

It is common that for certain uses, metal containers need an overcap. This happens when the content of the containers is not consumed at one time, but is used in successive times in a certain time. Therefore, to preserve the remaining product, it is necessary to protect it with a lid once the container has been opened. It can also be that the package is equipped with some device, such as a valve, that needs to be protected from blows and mistreatment, and therefore an external cap or cap that performs this function is added.

Specific cases of containers that normally use oversizes or caps, are those destined to cereal flours, milk powders, nuts, chips, chocolates and biscuits, aerosols and sprays, etc.

Most of these overcaps do not make a hermetic seal on the container, because they are limited to fit as best as possible over the mouth of the container. Its function is simply to protect the content for a reasonable time.

TYPES

In the market there are a variety of types of surcharges, which allow selecting the most appropriate solution for each particular case. To classify this diversity of options in homogeneous groups, we can do it based on: a) the material with which they are manufactured or b) by the design of the same.

Material : Two large groups attend the market, based on the material they are manufactured with:

1º.- Metallic , they are made of the same material as the container: tinplate, TFS, black sheet, etc. They are rigid or semi-rigid. Normally they are applied by friction. Photo # 1 presents an example of them. They are used for tobacco boxes, chocolates, cigarettes …

Figure nº 1: Metallic covers

They are manufactured in press, by a simple cutting and drawing process, topped by an edge curling operation.

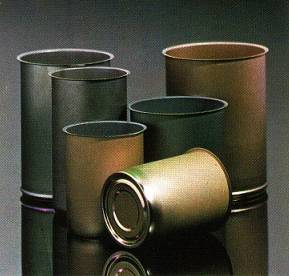

2nd.- Plastic: The raw material is PVC or polyethylene, they are produced by injection and are more or less flexible. They fit on the container by pressure. Typical examples of this case are aerosol containers or for dairy or meat products. See photo nº 2.

Figure nº 2: Plastic overcap

Design: Attending the design can be classified into:

– 1º.- Friction : The overcap fits over the mouth of the container, either on the double closing of the primitive lid or on a curl or reinforcement of the edge of the body of the container. The side skirt of the same is smooth and is introduced with a slight effort and does not require any additional element to stay in its final position. Usually used in containers that have been closed with a light seal, usually aluminum. They are usually made of rigid material. Figure 3 presents an example of one of them.

Figure nº 3: Container with friction overcap

– 2º.- By nails : In this option, the overcap is fixed by means of nails over the mouth of the container, which is equipped with more or less long threads. It is always used on containers that are closed with a thin seal of metal, paper or other material.

– 3º.- Pressurized: The overcap or cap is housed on the container, overcoming the resistance offered by its placement, by means of a continuous cord or an equidistant finger, in both cases located internally in the skirt of the cap. Typical example are the caps for aerosol containers. In drawing no. 4 there is a section of the detail of the fixing of the cap on an aerosol container. The fastening is usually done on the double closure generated by the union of the lid to the body of the container. To be able to place this type of plug, it must have a certain degree of elasticity as we will detail later.

Figure nº 4: Example of pressure overcap

The amount of possibilities presented by the combination of different materials with different designs is huge, so in this article we will focus only on a specific case, which is the most frequently used on metal containers. It’s about the plugs or overcaps under pressure.

DESIGN

Within the pressure surcharges and the two normal types used in the market and summarized above, we will start by looking at the one that has a more universal use:

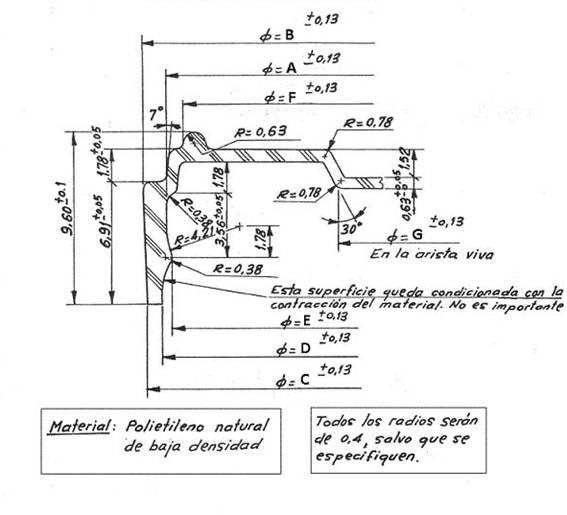

– 1º.- Cover with continuous cord . It is a cover designed to be housed in the double closure of the container, by means of: an inner peripheral groove, with the approximate shape of the closure in negative, and delimited by its lower part by a cord or jonquil which engages in the base of the closing, and in its upper part by a step that acts as a stop to the top of said closure. See drawing nº 5. This drawing has bounded by means of letters the measures that change with the diameter of the container, and on the contrary, those that can be considered fixed for all formats appear their numerical values.

Figure nº 5: Section of a pressurized overcap with continuous cord

The drawing No. 5 is a detail of a vertical section of an overcap of these characteristics. In addition to the groove with a lower finish in radius of 4.21 mm, the lower cord or rib finished by a radius of 0.38 mm, and the upper step also in radius of 0.38, you can see in the drawing other features of this cover as they are :

– A: An external tier at the top – height 1.78 mm – which allows to house the closure of another container stacked on this lid, giving stability to the stack.

– B: A bead of radius 0.63, in the upper flat part, which serves as a support to the central panel of the stacked container above, unloading its weight on the skirt of the overcap, which is the most robust part of it.

– C: A central tier, which strengthens the horizontal panel of the overcap

The variable dimensions are a function of the outer diameter of the double closure of the container. Below we give the approximate formulas that allow us to calculate these measurements from said diameter

A = Diameter of double closing – 0.10 mm

B = A + 2.50

C = A + 2.10

D = A + 0.25

E = A – 0.70

F = A – 2.0

There are many variants of this design that can be adjusted to the needs of each case. Its use is very widespread for products such as pates, powdered milks, cereals, coffees …

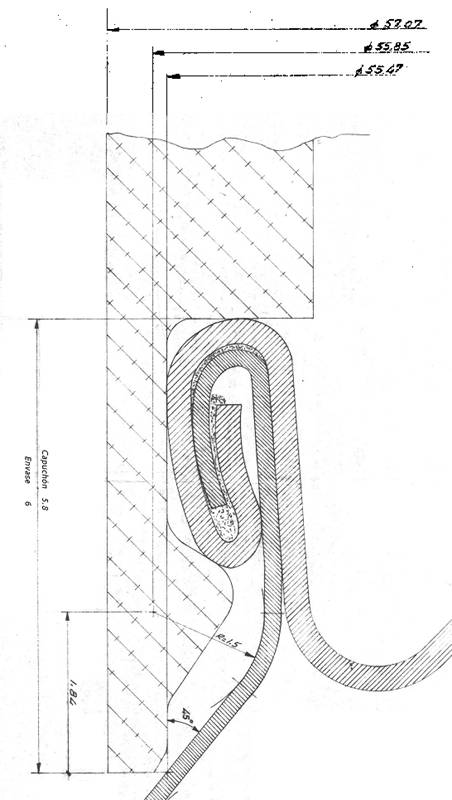

– 2nd.- Nail overlay : In this type, the continuous cord is replaced by a series of nails, and the step by some nerves in the same number as the nails, which go up and down the inside of the cap. Its height is much higher than the previous type and it is also fixed on the closure. As its main use is for aerosol containers, they are usually too high to accommodate the dome with its valve. They are not stackable because their slenderness is very unstable aerosols.

In figure 6 a section of the fixing area of this type of overcap is drawn on a notched aerosol. It appears with its main dimensions, for the specific case of a container of diameter 57 mm with dome 52.

Its outer diameter is matched to that of the container, and its base with the reference point of the notch. In the drawing, the function of the lower nail and the superior nerve on the closure is perfectly appreciated.

Figure No. 6: How to attach a nail overlay.

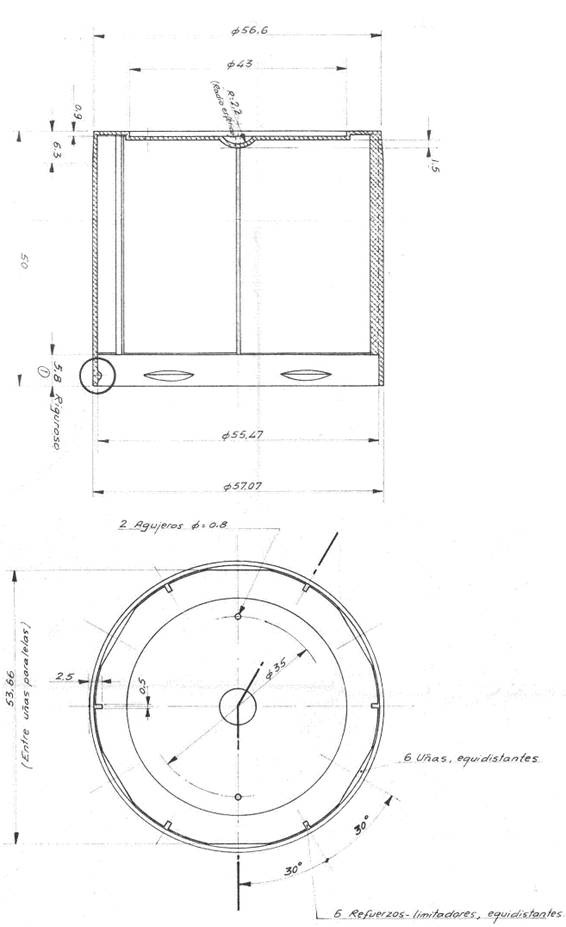

A plant and sectional elevation of the plug whose detail we have indicated, appear below in the drawing No. 7. It can be seen that the nerves are located between the nails and in an equidistant manner.

Figure nº 7: Plant and elevation in section of a plug with nails .

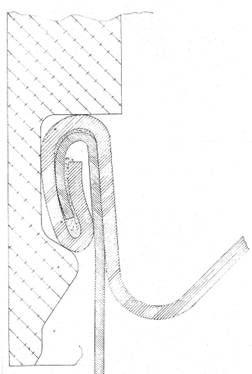

The detail of the dimensions of the nails of this cap is reflected in the detail nº 8.

Figure nº 8: Detail of the nails

With all that said, we have limited ourselves to exposing a few simple brushstrokes of the varied field of surtaxes, since their applications cover many other areas of packaging, such as cosmetics, medicines, chemical products …

0 Comments