Sin lugar a dudas contar con envases metálicos para alimentos de calidad es de vital importancia para la conservación de un producto. Cabe destacar que la fabricación de este tipo de elementos debe ser realizada de forma profesional, tomando en cuenta los detalles más minuciosos. En Mundo Latas encontrarás una amplia información sobre los envases metálicos y los diversos usos que se le atribuyen.

Más allá de proveer información detallada y actualizada sobre los envases metálicos te ayudamos a dar con los mejores materiales. ¿Tienes una empresa y necesitas un presupuesto? En ese caso, no tienes que perder tiempo en una exhaustiva búsqueda que puede no proveerte buenos resultados. Pues, con nuestros servicios te ayudamos a conectar con una variedad de tipos de envases metálicos para alimentos en tiempo récord.

Conoce cómo te ayudamos a dar con los mejores envases

Entendemos cuáles son las principales necesidades en este sector y trabajamos diariamente en generar buenos resultados. Somos conocedores de lo que se busca en un envase metálico para el uso de alimentos. Por lo tanto, conectamos con buenas referencias de la industria para asegurar una mercancía de absoluta calidad.

Finalmente, ten en cuenta que contamos con una experiencia comprobada en este sector la cual nos atribuye la capacidad de ayudarte a encontrar envases de metal para alimentos según tus propios objetivos. Nuestra intención es ayudarte a tener información de calidad sobre los envases, la cual sirva de punto de referencia sobre cuál puede ser tu mejor opción de compra.

A continuación te aportamos infomación técnica sobre envases metálicos que debes conocer para tomar la mejor decisión.

1º . UTILIZACIÓN DE ACEROS RECUBIERTOS : LOS ENVASES

2º . FUNCIONES FUNDAMENTALES DE UN ENVASE

3º . PRINCIPALES MATERIALES DEL ENVASE

4º . ENVASES EN ACEROS RECUBIERTOS : CRITERIOS DE CLASIFICACIÓN E IDENTIFICACIÓN

5º . PRINCIPIO DE FABRICACIÓN DE LOS ENVASES

1º.- UTILIZACIÓN DE ACEROS RECUBIERTOS EN ENVASES METÁLICOS PARA ALIMENTOS

Se entiende por acero recubierto, a acero laminado de bajo espesor, que ha sido protegido por ambas caras por otro metal que lo salvaguarda de los ataques externos.

Cuando hablamos de envases metálicos para alimentos existen dos tipos principales: hojalata y TFS, y en pequeñas cantidades la chapa galvanizada.

✅ HOJALATA: Acero recubierto de estaño

✅ TFS: Acero recubierto de crom

✅ CHAPA GALVANIZADA: Acero recubierto de zinc.

UTILIZACIONES DE LOS ENVASES METÁLICOS PARA ALIMENTOS

El mundo de los envases metálicos para alimentos se mantiene en constante innovación. Nosotros tenemos como objetivo ofrecer un servicio de calidad y siempre en constante evolución. Es por ello, que si estás buscando información sobre este tipo de materiales estás en el lugar idóneo. Pues, conocemos cuáles son los envases de metal para alimentos más buscados y todo en cuanto a este tema.

CONTAMOS CON ENVASES METÁLICOS PARA ALIMENTOS COMO:

✅ BOTES DE CONSERVAS, BEBIDAS, PINTURAS…

✅ AEROSOLES

✅ BIDONES, BARRILES.

✅ CAPSULAS, TAPONES.

✅ BANDEJAS PARA ALIMENTOS

ADEMÁS PARA:

✅ PLATOS Y BANDEJAS

✅ JUGUETES

✅ ANUNCIOS Y PLACAS PUBLICITARIAS

2º.- FUNCIONES FUNDAMENTALES DE UN ENVASE METÁLICO PARA ALIMENTOS

- a) Los envases metálicos para alimentos tienen como función principal ser la barrera protectora entre el producto y el medio exterior, por lo que protejen al contenido de posibles agresiones.

Por tanto el embasado no deja de ser una barrera contra:

- OXIGENO DEL AIRE EXTERIOR (caso extremo: envase al vacío)

- HUMEDAD DEL AIRE

- MICROORGANISMOS

- LUZ U.V.

Por otro lado, los envases metálicos para alimentos son un perfecto mecanismo de defensa para agresiones físicas o químicas como:

- CHOQUES (durante la manipulación, caídas)

- APILADO (almacenamiento)

- PRESIÓN (durante la esterilización)

- TEMPERATURA (durante la esterilización

- INTERACCIÓN QUÍMICA ENTRE ENVASE Y EL EXTERIOR

- INTERACCIÓN QUÍMICA ENTRE EL CONTENIDO Y EL ENVASE

- b) Los envases metálicos para alimentos son una barrera indispensable que separa el contenido del continente, usando las siguientes técnicas

✅ LLENADO

✅ CIERRE

✅ VACIADO (separación)

- Los envases metálicos de alimentos no dejan de ser un soporte que permite que la manipulación del producto sea más cómoda y, por tanto, facilitan su posterior almacenamiento.

- El envasado de un producto debe llamar la atención y ser visual, ya que es como el consumidor final va a ver presentado el alimento

- Los envases metálicos para alimentos deben ser fácilmente reciclables para su posterior desaparición

- Deben poder destruirse de forma natural o voluntaria

- La reutilización de envases metálicos para alimentos es clave para su buen uso.

- Intentamos fabricar un embasado que se produzca fácilmente, de forma económica y homogénea del envase en si mismo.

3º.- PRINCIPALES MATERIALES DEL ENVASE METÁLICO PARA ALIMENTOS

Los envases emplean principalmente los siguientes materiales para su construcción:

✅ ACERO RECUBIERTO

✅ ALUMINIO

✅ VIDRIO

✅ PLÁSTICO

✅ CARTÓN

✅ PAPEL

✅ MADERA

✅ TELA

✅ MATERIALES COMPUESTOS (cartón-aluminio, papel-aluminio, papel-plástico…)

✅ OTROS MATERIALES AUXILIARES. (tintas, barnices, gomas, colas…)

4º.- ENVASES METÁLICOS PARA ALIMENTOS: CRITERIOS DE CLASIFICACIÓN

A continuación te exponemos cómo se pueden clasificar los diferentes envases metálicos para alimentos.

A.- POR EL CONTENIDO DEL EVASE

a.- CONSERVAS: Alimentos esterilizados

b – BEBIDAS: Cerveza, Colas, Refrescos, Bebidas energizantes…

c – OTROS PRODUCTOS ALIMENTICIOS: Aceite, Leche, Jarabes, Bizcochos, Productos en polvo.

d – NO ALIMENTICIOS: Limpieza, Fitosanitarios, Cosméticos, Farmacéuticos.

e – INDUSTRIALES: Lubricantes, Pinturas, Barnices, Tintas, Grasas.

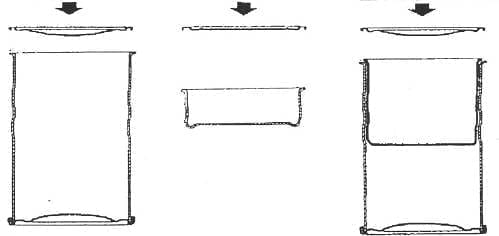

B.- POR EL NUMERO DE PIEZAS QUE LOS COMPONEN EL EVASADO METÁLICO PARA ALIMENTOS

a – 3 PIEZAS b – 2 PIEZAS c – CON COMPARTIMENTOS

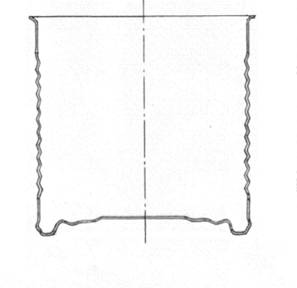

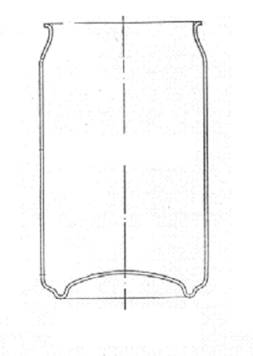

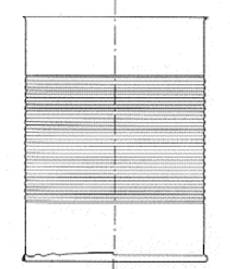

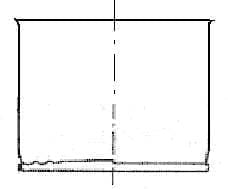

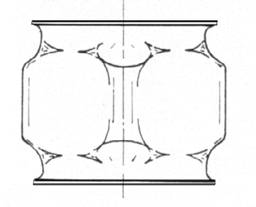

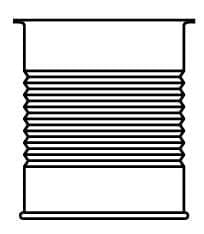

C.- POR LA FORMA DE REALIZAR EL CUERPO DEL ENVASE

a – ENGARGOLADOS

b – SOLDADOS ELÉCTRICAMENTE

c – SOLAPADOS

e – EMBUTIDO – REEMBUTIDO

f – EMBUTIDO –ESTIRADO – PLANCHADO

g – ACORDONADOS

h – ENTALLADOS (Apilables)

i – EXPANSIONADOS

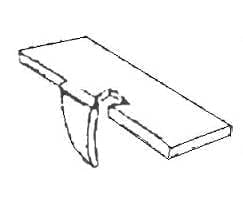

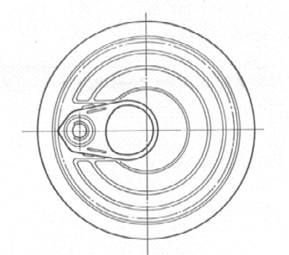

D.- POR EL MODO DE APERTURA DEL ENVASE METÁLICO PARA ALIMENTOS

a – CORTE DE TAPA (abrelatas)

b – INCISIONES EN EL CUERPO

c – FÁCIL APERTURA PARCIAL

d – FÁCIL APERTURA TOTAL

E.- POR SU CAPACIDAD

1/1 (4/4) 850 cm3

½, 1/3, 1/4, 1/12…

2/1, 3/2, 5/4, 5/1…

F.- POR SU FORMA DEL ENVASE

a – REDONDA CILÍNDRICA

b – REDONDA TRONCOCÓNICA

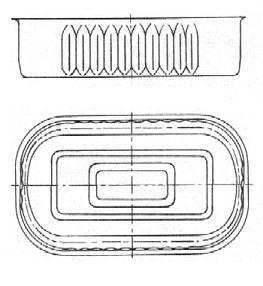

c – RECTANGULAR O CUADRADA:

– PRISMÁTICA

– TRONCOPIRAMIDAL

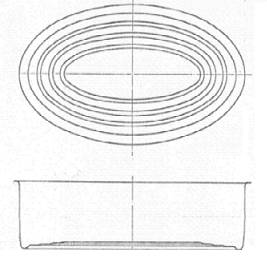

e – OVAL

f – OBLONGA

g – TRAPEZOIDAL

En general las latas que no son redondas se denominan “de forma”

G.- POR SU ALTURA

A – BAJAS

B – MEDIAS

C – ALTASSe emplean para una capacidad dada en función de su altura.

H.- DIMENSIONES (en mm)

LATAS REDONDAS: diámetro nominal de tapa X altura del cuerpo

Ejemplo: 99 x 118 (lata de 1/1)

LATAS DE FORMA: longitud X anchura de la tapa X altura del cuerpo.

Ejemplo 116 x 95 x 90.5 (lata 1/1 Jockey Club)

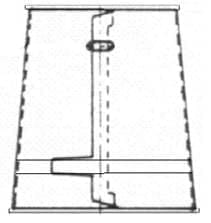

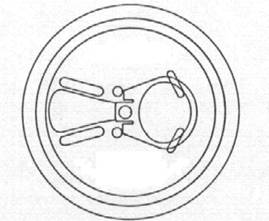

5º.- PRINCIPIO DE FABRICACIÓN DE LOS ENVASES METÁLICOS PARA ALIMENTOS

A.- SECUENCIA GENERAL:

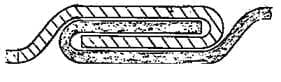

B.- ESQUEMA DEL PROCESO DE IMPRESIÓN Y BARNIZADO

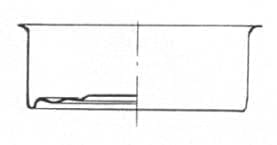

D.- ESQUEMA DEL PROCESO DE FABRICACIÓN DE ENVASES 3 PIEZAS

¿Te ha parecido interesante esta información sobre envases metálicos para alimentos? desde Mundo Latas queremos asesorarte para que elijas el mejor envase para tu alimento.

Te ofrecemos asesorías y presupuestos online

¿Es tu primera vez comprando envases metálicos para conservas? Te contamos cómo comprar envases de metal para alimentos explorando muy bien todas tus ofreceremos la mejor atención.

Además, no solo te ofrecemos asesorías impartidas por profesionales en el sector. También, te proporcionamos una herramienta muy práctica que consiste en generar un presupuesto en línea tomando en cuenta tus peticiones.

Finalmente, si eres una empresa y quieres dar a conocer tus productos no dudes en ponerte en contacto con nuestro equipo. Ten en cuenta que ofrecemos servicios de publicidad a gran escala para ayudarte a vender tus envases metálicos para alimentos y otros productos afines. ¡No te lo pienses más!

0 Comments