SUMMARY

Description of this container and a low speed line for its low cost production.

PREAMBLE

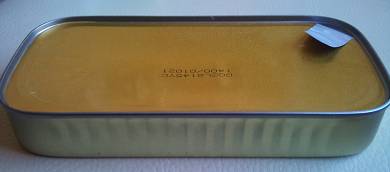

The “Fiesta” packaging is a format that is widely used in the Spanish market for asparagus preserves, although it also has other uses such as “piquillo” peppers. It is a traditional container from the Rioja-Navarra canning area. See photo nº 1

Figure nº 1: Carton type “Fiesta” containers

Its shape is rectangular – parallelepiped – and its construction is of the “two-piece” type, that is to say, low-height sausage. Therefore it allows a similar presentation to an extended plate that adapts very well to elongated products.

The market of asparagus for export from South America or China, uses it frequently and therefore the manufacture of it has been developed in certain countries, even more since it has an easy opening lid, since its simplicity to open it has improved. although it is still used with a conventional flat lid, but in it, due to its low height, it is not easy to use a classic opener for opening.

CONTAINER

As we have already said, its base is rectangular, with rounded corners. It is presented in the market in two different dimensions:

A.- RR 155 x 81 x 26. That is to say, its nominal measures are: length 155, width 81 and height 28. Its capacity is 212 cc ..

B.- RR 170 x 81 x 28. Capacity 250 cc.

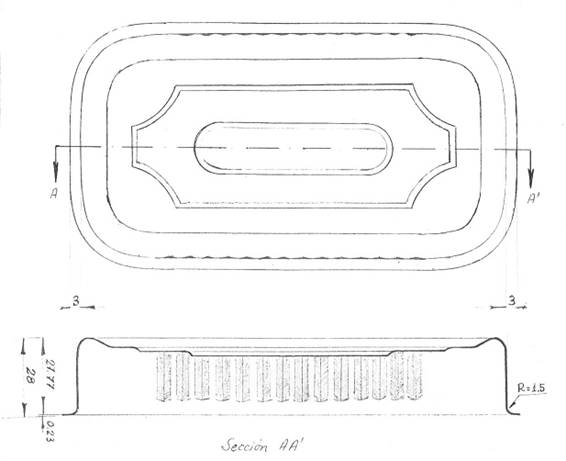

The capacity of 250 cubic centimeters allows a drained weight of 150 grs. and that of 212 cc of 125 grs. Figure 2 shows a plant and section of this container with some of its main dimensions, although they may vary slightly from one manufacturer to another

Figure nº 2: Package “Fiesta”

Its bottom is reinforced with several gradients, since it is a sterilizable container. Also his body usually presents vertical ribs that fulfill the functions of:

– Eliminate the undulations and deformations generated in the walls of the container during the drawing.

– Reinforce these walls during the process and use

– Improve your appearance.

The market offers several versions of easy-open lid for this format, such as tinplate with ring, applied by double classic closure, or flexible aluminum thermoformed, see photo no. 3

Figure nº 3: Container of asparagus with easy opening

MANUFACTURING

The main reason for this work is to present a manufacturing line for this type of container. It is not a complex, expensive and high-performance installation, but a simple and economical means. Most of the equipment mentioned may already exist in a packaging factory or be purchased in the secondary market without difficulty.

Figure 4 presents a schematic of the line that we are going to describe. The speed of the same is approximately 50 containers / minute, enough for what is usually a typical order in this format.

Basically the line is made up of two presses – stuffing and trimming – with their complementary equipment. Let’s see it in more detail

1º.- The material prepared – lithographed and / or varnished – is fed to a press of the Trio or similar type of 40 Tm. and enough career. Feeding can be simplified a lot by doing it vertically. About this type of food we refer to what is described in the work:

– Vertical feeding in presses for sausage packaging

This press will be used with the embossing die – 1st operation -. In the scheme it is indicated under number 1

2 .- The working conditions are facilitated by placing around the press of 1st operation a platform of adequate height for the feeding of strips is comfortable, – No. 2 of the drawing. – It will be positioned on it in a higher plane, a table-warehouse, which will receive the pallet of strips cut material. No. 3

3º.- A conveyor will collect the containers at the exit of the press and will move them to a magnetic lift, which will discharge them on a fall by gravity towards the next press. In this fall will be installed a maximum sensor, whose function is to stop the production in the 1st press when it is filled with packaging due to problems in the 2nd press. No. 4 and 5

4º.- A 2nd press, of clipping of the remaining material and definition of the tab. It will be equipped with a feeding system – for example pneumatic – that allows the feeding piece by piece. The container is fed face down, and once cut it falls through the cutting blade. The ring-shaped cut is removed from the back.

Figure nº 4: Line diagram

5º.- For the packaging, the ideal thing is to have a more or less automatic palletizer, but if it is lacking, it can be replaced by a conveyor of quite a width, at least 70 cm, and a certain length – 7 meters or more -, what will become of accumulator of containers. In the same the boats are ordered by rows in depth. Also in it will be mounted a maximum sensor to stop the activity of the 2nd press if the conveyor is full. No. 7 of the scheme.

6º.- If the previous conveyor is used, to form the pallet of containers it is possible to put a cartola or dihedral of wood or metallic sheet, which has the three dimensions of the pallet of containers in its three senses. It is equipped with a turning axis for its subsequent opening, once it has been completed in a pallet of containers. No. 8 of outline

7.- A work table surrounds the palletising area. Made in two parts, a fixed input, and another rotating on the axis of the dihedral. The second part will rotate on its axis to evacuate the full pallet. No. 10 and 11 of outline. The operator in charge of the packing task works on it.

8º.- The empty wooden pallet is deposited on a hydraulic lifting table located inside the dihedral. A system of detectors allows to maintain a constant height of the pallet, coinciding with the arrival of containers ordered by rows. No. 12 of outline.

9.- A roller conveyor facilitates the evacuation of a full pallet, previously rotating the operator’s platform. No. 13

10.- The system of complete with a table to have at hand the pallet of intercalators or separators between layers of containers. It is located on the boat accumulation conveyor. No. 9

Also in the vicinity there will be a system of wrapping and protection of the pallet full of containers, either with stretched film or cardboard covers.

The design of this line is foreseen to access with the material on its front and the withdrawal of containers on its right. Depending on the access possibilities, your configuration can be changed.

The line can be operated with two work stations, one at the head in the 1st press and another in the packaging.

0 Comments