SUMMARY

Determination, in a simple way, of the applied load of powder varnish on the inside face of the side weld, of a can once finished.

INTRODUCTION

The electric welding, which joins the side seam of three-piece cans, is a sensitive area that must be protected from the action of the product that these cans will contain. If this is not done, it will quickly oxidize after welding, when the protective tin layer disappears, which melts due to the heat generated during the operation and remains attached to the copper wire that acts as the electrode. This incipient oxidation will facilitate the subsequent attack of the product to it and its very possible perforation.

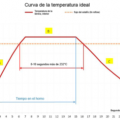

Currently, it is common to protect the welding line internally by means of a varnish, which is applied in the powder state by an electrostatic process, and subsequently melted and polymerized by the action of heat through a continuous furnace, mounted below of the varnishing station.

In the work of this Web:

the characteristics, properties and application of this powder varnish have been developed, as well as the quality control of the application operation thereof. Therefore we recommend reading it because we will not touch on these topics here. However, in this work, the control system for the correct loading of said varnish was developed to be able to do it only on the part of the can manufacturer, for that reason we will now explain an easy procedure to be carried out also by the packer or anyone who wants to verify the weight of varnish applied once finished in packaging.

METHOD

– Choose randomly the sample can to perform the test.

– Using scissors with a curved tip for sheet metal cutting, cut an approximately 5-7 mm wide strip in the area of the weld, ensuring that it is centered on the strip. All of it must be protected from varnish to protect the seam, usually white. In the case of packaging bodies completely varnished by interior, care must be taken that there is no presence of this total varnish on the cut strip, that is to say that it is limited to the area that has received the powder varnish.

– Measure exactly the dimensions of the strip (width and length) and calculate its area. Previously it should straighten or cut the ends if they are blinked or affected by double closing.

– Weigh the strip on a precision scale, at least exactly hundredths of a gram.

– Remove the solder varnish – polymerized electrostatic powder – by rubbing with a cotton soaked in a suitable solvent. Methylene trichloride, also referred to as chloroform or trichloromethane, is recommended.

– Reweigh the clean strip of varnish.

– Determine, by weighing difference, the weight of varnish that contained the strip.

– Calculate, taking into account the area of the strip, the amount of powder varnish per unit area (for example in centigrams per square centimeter).

– Transform this value to gr / m2.

TEAM

– Scissors for sheet metal cutting

– Cotton

– Methylene trichloride

– Precision scale

SPECIFICATION

Weight of varnish film applied over the recommended solder:

– Interior naked: 60/70 gr / m2

– Interior varnished: 85/120 gr / m2

In the case of cans with their interior completely varnished, a higher load is recommended, since the potential attack will be more concentrated in the area of the welded seam, since the rest is more protected.

0 Comments