Electrostatic powder coating and interior curing is a process that offers several important advantages and features for the protection of metal containers. Here I explain how this process works and its key aspects:

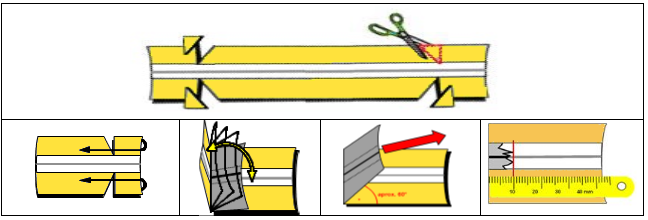

Electrostatic Powder Application

- Application Process:

- The powder coating is applied electrostatically on the area to be protected. This is achieved by projecting a cloud of fluidized powder with the help of air completely free of moisture and traces of oil.

- Simultaneously, an electromagnetic field is generated which allows the dust particles to remain adhered to the metal surface, as these particles are charged with static electricity.

- Equipment Used:

- The powder applicator is designed as an extension of the welding arm, allowing the container body to move from the welding position to the powder application position immediately and in the same position. This ensures that the varnish is applied before the weld can oxidize.

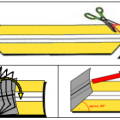

Electrostatic Powder Baking

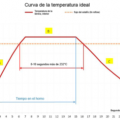

- Curing Process:

- Once the powder has been applied, the containers are gently transferred to a longitudinal oven for curing of the coating. The transfer should be as smooth as possible to avoid partial release of the powder due to vibrations and to keep the seam in the correct position with respect to the heat source.

- During the oven run, the containers approach each other, slowing down the speed to increase the time spent in the oven. The length of the oven is calculated to ensure adequate polymerization of the varnish.

- Quality Control:

- During the advancement of the container inside the oven, a rapid temperature increase is initiated on the metal, which facilitates the polymerization of the varnish and ensures effective protection.

Advantages of Electrostatic Powder Coating

- Chemical Resistance: Offers excellent chemical resistance.

- Durability: Long shelf life.

- Color Versatility: Generally offered in white, but also available in gold, ivory and other shades.

- Sanitary aspect: The white color predominates for its sanitary aspect.

Additional Considerations

- Protection against oxidation: It is very frequent and highly advisable to perform welding in an inert atmosphere, injecting nitrogen into the area to prevent oxidation.

- Powder adhesion: The adhesion of cured powder on a rusty weld is poor, so it is crucial to apply the varnish immediately after welding.

This process is essential to guarantee the internal protection of metal containers, especially those containing food products or chemicals that may be corrosive.