To improve the dosing of electrostatic powder in welding, it is essential to follow some guidelines:

- Make sure that the particle size of the powder is in the order of a few microns and that it does not contain particles larger than the average thickness of the application. The smaller the particle size, the more effective the coverage, fluidity and good distribution of the electrostatic powder along the weld.

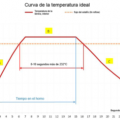

- It is necessary to cool the powder to improve its fluidity along the pipelines. The temperature of the supply air must be below 20 °C.

- It is also important to cool the weld prior to powder application. This improves the application and increases the service life of the tools used.

- Once the powder has been applied, the weld must be cooled at the exit of the oven. This increases the flexibility of the varnish, which is necessary for flanging operations.

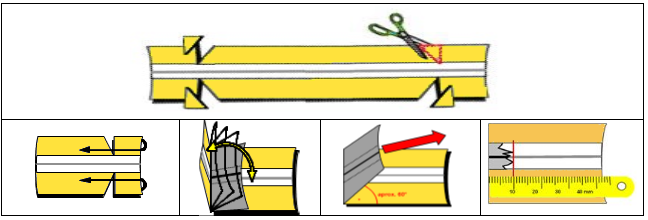

- The amount of powder applied should be wide enough to cover, with a certain overlapping, the previously reserved area of flat varnish necessary to make the weld.

- To verify a good application of powder coating, the following parameters should be controlled: coating load, polymerization, porosity and behavior in the sterilization process.

By following these guidelines, the dosing of electrostatic powder in the weld can be improved.

0 Comments