To check the seam on a metal container, follow these steps:

- Visual examination: Perform a careful visual examination of the entire container, paying special attention to the seams. Look for defects such as edges, dents, edge depressions, peaks, folds, protruding flanges and overlap defects. Also watch for other less noticeable defects, such as flaws in the tinplate or small holes in the weld of the side seams.

- Determine the origin of the defects: During the visual examination, try to determine if the defects are due to damage caused during transport or if they occurred at the processing facility. Record all observations.

- Mark and record defects: It is important to locate packaging defects, mark and record them to keep proper quality control.

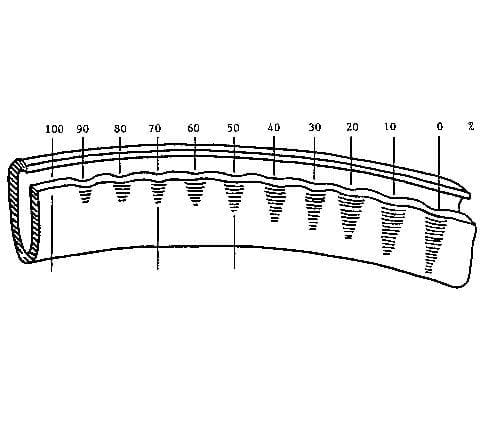

- Non-destructive measurements: Perform non-destructive measurements of seams or fasteners using specific tools, such as a micrometer or seam gauge. These measurements may include seam thickness, seam width, seam height, seam overlap and seam pressure.

- Destructive analysis: If necessary, perform a destructive analysis of the seams by opening the package and examining the integrity of the internal seam. This may reveal problems that were not detected during visual inspections and non-destructive measurements.

Remember to always follow the specifications and tolerances established by the packaging manufacturer and the regulations applicable in your country or region.

0 Comments