To check the seal of a pouch, you can follow these methods:

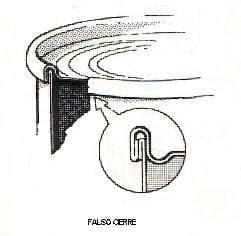

- Visual inspection: Verify if the seal is uniform and continuous, without wrinkles, folds or deformations. Make sure the seal is of adequate width, usually at least 3 mm.

- Water tightness test: a. Fill a container with enough water to completely submerge the pouch. b. Apply an inward pressure on the pouch, you can do this by pressing gently with your hands. c. Immerse the pouch in the water, making sure it is completely covered. d. Maintain pressure on the pouch for the specified time (usually about one minute). e. Observe if there are bubbles coming out of the pouch seal. If there are no bubbles, this indicates that the seal is properly sealed and there are no leaks. Otherwise, if you see bubbles coming out of the seal, this indicates that there is a leak and the seal is not properly sealed.

- Dye penetration test: Apply a dye to the seal area and let it act for a specified time. Then, wipe off the dye and check if it has penetrated the seal. If the dye does not penetrate, the seal is well sealed.

- Seal strength test: Use a seal strength testing device to measure the force required to open the seal. If the strength is adequate according to the manufacturer’s specifications, the seal is properly sealed.

It is important to perform these tests on a regular basis to ensure the quality and safety of the product packed in the pouch.