Chloride, specifically sodium chloride (NaCl), can have a corrosive effect on tinplate containers (TFS). Corrosion can be caused by humidity and the presence of chlorides in the environment or in the contents of the container.

Corrosion can weaken the packaging material, which can lead to leakage or contamination of the packaged product. To minimize the corrosive effect of chlorides, some measures can be taken:

- Use packaging materials with suitable protective coatings that are resistant to corrosion.

- Ensure that containers are dry before storage and transport.

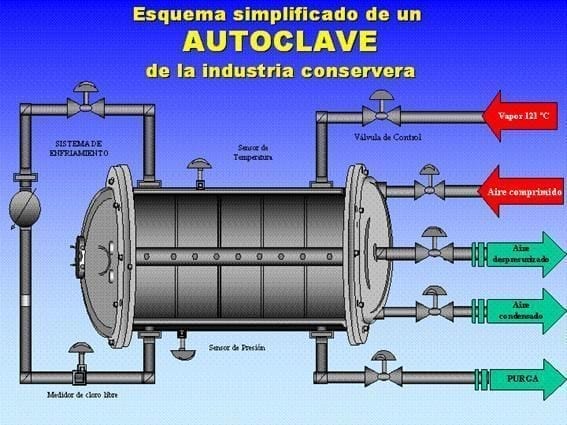

- Control the conditions of the water used in the sterilization and cooling processes, and consider the use of additives that reduce corrosion.

- Choose secondary packaging materials, such as cardboard boxes, with low chloride and sulfate content.

Taking these precautions can help protect the integrity of the TFS package and ensure the quality and safety of the packaged product.