PROLOGUE Man is the only being of Creation that is capable of taking advantage of the elements of his environment, modifying them in such a way that they bring him more benefits than those inherent in their natural state.

To do so, he brings his faculties into play and, with experience, gains new knowledge that translates into new advances.

Thus, step by step, generation by generation, his achievements progress exponentially.

Among man’s first objectives has always been the optimization of the perishable resources he consumes, mainly food.

Hence, the means to conserve them when there is a surplus of them, so that they can be used when the shortage appears, has been a matter that has interested him.

The canning industry is part of the answer that man’s experience has given to this need to balance his needs, taking into account the productive cycles of nature.

But for this industry to exist, it needs others to provide the appropriate means.

And here we find the metallurgical industry.

Being Spain a country rich in livestock, fishing and agriculture resources, it was also called to be rich in the conservation industry.

Therefore, the metalworking sector also had to be important.

It has been more than a century and a half since it began its journey.

Therefore, enough generations have passed – at least five – to have a perspective of its history.

The same in Spain I think it has yet to be written, at least in some detail.

I do not have enough data to dare to write a history of the metalworking industry in Spain, even if only in a very abbreviated form.

Even so, I cannot resist the temptation to present some notes as a starting point for further work in more depth.

I am sure they will be full of mistakes and oversights that will always be involuntary.

I apologize in advance for all of them.

Note: Throughout the text, at the end of some paragraphs there are a series of numbered references in parentheses, which at the end of each chapter expand on the information in these paragraphs.

———

BACKGROUND The background begins with the industrial appearance of tinplate in Spain. The same was known in the craftsmanship but the first industrial installation for its manufacture begins to produce in the year 1731 in Andalusia during the reign of Philip V, the first Spanish Bourbon. Specifically in the town of Juzcar, located in the Serrania de Ronda in the province of Malaga and under the name of “La nunca vista en España Real Fábrica de Hoja de Lata y sus Adherentes, reinando los siempre invictos monarcas y católicos reyes don Felipe y doña Isabel Farnesio”, of course, had a “secret room” for tinning, which made German workers brought for the purpose. It should come as no surprise that it was in this region and not further north that this activity began. Andalusia was one of the first Spanish areas where the presence of European technology and capital was felt. The mining operations in the provinces of Almería, Huelva and Jaén are good proof of this. Their location in the Serranía de Ronda was possibly linked to the abundant presence of wood, which was needed as fuel.

Tin of the year 1840

However, its use for the manufacture of containers did not begin until very late in the following century.

At the end of the 19th century – this time in the north of the peninsula – Altos Hornos y Basconia began the production of tinplate in response to the growing national demand of the canning industry.

2.- THE PRINCIPLES In Spain the activity in the sector started later than in the rest of the industrialized countries of Europe (England, France, Germany). There is a work already organized in the form of small family-type workshops in the second half of the nineteenth century. The first sectors where the use of metal packaging began were, in this order: A.- Canned fish. B.- Vegetable preserves. C.- Biscuits, candies and industrial products. Fish consumption is widespread in Western Europe, whose countries (France, the Netherlands, Portugal and, of course, Spain) have had a large fishing fleet since time immemorial. This business soon saw the possibilities presented by canned fish. The first news about this way of preserving fish came to Galicia from the hand of a French ship that was wrecked on the Costa de la Muerte in 1840. In that fishing area of A Coruña, which already had a great family tradition of salting and smoking sardines, the first canning factory was set up that same year, specializing in that fish, which was fried before being canned. Fried sardines and lamprey and pickled oysters were the first foods to appear in the Spanish market. Later – in the first years of the 20th century – it was discovered that it was better to cook the fish inside the can than to fry it previously, which simplified and cheapened the process, and its use spread rapidly.

A canning factory in the 19th century In 1850 the first vegetable canning plant in Spain appeared in La Rioja, it was set up by Gutiérrez de la Concha in Logroño.

The canning of paprika powder, tomatoes and peppers opened up the canning sector.

It started in La Rioja and was soon followed by Murcia.

The small rectangular cans of paprika from these early times – some of which have survived to the present day – are authentic works of art.

From the beginning, the manufacture of biscuit tins, candy tins and oil cans was located in Catalonia.

In this area also arose a series of mechanical workshops that manufactured presses and specialized machines for the sector being the cradle of this industry in Spain such as Blanch and Juan Capella in Badalona.

The latter was founded in 1922.

Today there are still some beautiful tins of cookies or candies from this period that are museum pieces.

In Bilbao and in 1905 the first can seamers began to be manufactured.

The Norwegian Johannes K. Somme, Norwegian consul in Bilbao, born in Stavanger, the most important canning center of the time, set up a workshop and manufactured spare parts for the Norwegian and German seaming machines that he represented and had sold in Spain and Portugal.

His sons and successors Jan, Carlos and Jacob, in spite of the wars, manufactured their own models of seaming machines, presses, folding machines, shears, marine engines, irrigation pumps, gas generators, portable fireplaces for the front lines, etc.

The company has more than 200 workers and manufactures more than 7000 can seamers that are exported all over the world.

Almost centenary SOMME S.A. closes definitively in 1990.

Following the family tradition, his grandson founded in 1997 JK SOMME S.L., today again one of the biggest can seamer manufacturers in the world.

The manufacturing evolved with the century and already in the “twenties” there were well organized industries with modern equipment imported from Germany or North America that were able to produce cans at 120 cans/minute (½ Kg. round) in different parts of Spain.

From this period we can mention for example in Catalonia: G. de Andrei y Blanch, Artes Metalgraficas Hispano-Lupcinski (1923); in La Rioja: Metalgrafica Logroñesa of the Orduña family (Logroño 1924), Envases Valentín Álvarez (Calahorra 1924), Envases Vicente Berbes (Calahorra 1925) Envases Metálicos Moreno (Calahorra 1931) and other smaller ones; Barrenechea in Vizcaya, etc.

The rectangular containers were made in an artisan way by welding the side seam with manual welders of the “tinsmith” type.

The printing of the metal was done on flat machines sheet by sheet, then placing them on trolleys with grids that were introduced into static ovens made of masonry that heated using wood as fuel.

The designs were really a filigree, always line drawings – without weft – whose photoliths were specifically “litos”, i.e. stones – hence the name – attacked with acids.

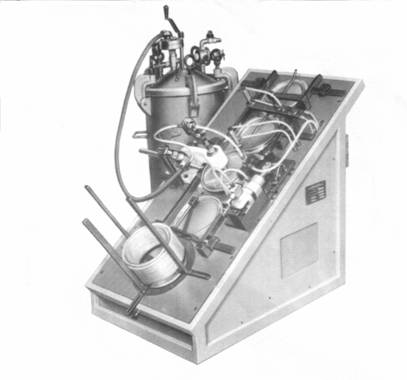

Table-top press of the time

3.- CONSOLIDATION After the Civil War, the activity suffered a certain stagnation due to the lack of demand capacity of the internal market and the isolation with the exterior.

However, it had the positive side of necessarily favoring the development of its own resources.

Thus, more equipment manufacturers appeared.

For example, Zenzano in shears (La Rioja), while others that began their activity much earlier, such as Blanch and Capella (Barcelona), remained active.

The manufacture of containers gradually increased and with it the number of producers.

New manufacturers continued to appear in the geographical areas mentioned above, especially in La Rioja (among others Broqueta Berbes founded in 1942 by Felipe Broquetas and Mario Fernández, Envases Esteban Lana founded in 1943…), Murcia and Catalonia, which made significant progress.

To these are added the area of the Strait of Gibraltar (fish), the Basque Country and Madrid.

Companies such as G. de Andrei y Gines Llamas – a family business of great prestige (1) – in Barcelona, Metalsa in the Strait of Gibraltar, Derivados de Hojalata in Murcia, are examples of dynamism in this period.

This was intended to cover a need of the canning industry in the area.

(2) (1) The Llamas family maintained the industrial activity of this company for three generations.

The grandfather Gines Llamas Martinez created it in Badalona in 1923 under the initial name of “Artes Metalgraficas Hispano-Lupcinski”.

After the civil war – in 1956 – it changed its name to Gines Llamas, greatly improving its facilities and specializing in quality industrial containers (mineral oil and paints).

The plant had the complete cycle including lithography and varnishing.

The father took it to its maximum importance to reach with the third generation a period of readjustment and merger with other companies.

It had an excellent technical team headed by engineer Sol.

(2) This company was headed for a long time by a woman: Pilar, who managed it with great capacity and efficiency, becoming a reference in the sector.

She was a pioneer of her time, as it was not common at that time to entrust women with management positions.

4.- EXPANSION From the 1950s onwards, the good performance of the market triggered the arrival of the first multinationals such as Carnaud (France) which, together with the main fish canneries in the Galician area, set up Carnaud-Galicia in Corujo (Vigo). With this company, the manufacture of “decollage” type containers acquires a large volume by using fast lines at 200 containers per minute with its own technology and equipment (3). Also within the fish sector there are some other important metal-graphic companies such as Megasa in Villagarcia de Arosa (4). In this sector, the machine manufacturers available on the market are French (Lubin and Sudry), Portuguese (Cerlei, Vulcano, Amorosa) and to a lesser extent Spanish (Somme – in Bilbao -, which was focused on the cannery seamer market). Blanch Continental Can (USA), Carnaud (France) and Metal Box (England) joined forces and took a stake in a very active metalworking company founded shortly before in Andalusia (Linares 1952) – named Olmesa (5) – and began a rapid expansion in Valencia – Cidesa (Cuart de Poblet 1961) (6), La Rioja – buying Metalgrafica Logroñesa in 1963 – and Seville – buying Unimasa (Dos Hermanas 1665) in 1968 – touching all market segments under the name Cía. Internacional de Envases. This company introduced “twist-off” closures as a novelty in Spain (7). The machinery used for these closures as well as for the different conventional containers is of their own manufacture. The Murcia area grows strongly, with Sánchez Rex (Molina de Segura) standing out as the most aggressive and leading company. This family company will eventually set up factories in Navarra (Murchante in La Rivera Navarra) and Extremadura (Montijo, Badajoz). Unfortunately its life was not very long and it was forced to close its doors after a series of economic and domestic problems (8). Vivancos (Murcia) was also created by the family of the same name in 1972 (9) – later Mivisa – which had its origin as a warehousing company of imported tinplate, a very strong market in that period due to national supply limitations. This industry maintained a steady evolution in the following decades, becoming a reference point for vegetable preserves at the end of the 20th century, To achieve this, it set up new factories in other regions of Spain (Aldeanueva de Ebro, La Rioja in 1989, Extremadura in 1993, in Murcia (2nd factory in Las Torres de Cotilla) in 1995, in Galicia in 1997 and finally in Asturias in 2002). Along with Sánchez Rex and Vivancos, many other companies competed for the Murcian and even national market, such as Metalgráfica Murciana, Auxiliar Conservera (Molina de Segura 1961)… The latter company would later set up a second factory in Seville. This is not the time to list all the companies, as this would be far from the purpose of these notes. The equipment used was mostly imported from Italy, where several manufacturers had developed simple machines that gave a good service to the market. We can mention Bencini and La Meritermica in the low range and FMI and Cevolani with better quality, a good part of this equipment arrived in Spain through Ribeiro, an important equipment trader.

A number of family-owned companies continue their development in the La Rioja area.

Among them, Envases Metálicos Moreno -which already has several decades of history- stands out for its good products and its production capacity, as a result of important investments and expansion of facilities.

It is accompanied by others: Comercial de Envases, Ballujera, Broquetas -all of them located in Calahorra, which is the true capital of this industry in the northern area- and also Menasa, Galan… All of them are dedicated to vegetable preserves, with the exception of Comercial de Envases, which mainly deals with the industrial sector (paints).

Next to it, in Casetas (Zaragoza), Grumetal, with technical assistance from the French company Massillí, developed a wide range of products: aerosols, canning containers, capsules… At the beginning of this period, in other areas of the peninsula with little tradition in this type of industries, some appeared, although certainly with little success and soon disappeared from the market: Unimasa started in Dos Hermanas (Seville) by a group of canners dedicated to containers for olive oil and vegetables, it was soon bought by Cidesa as mentioned above.

Metalgrafica del Mediterráneo in Reus (Tarragona) founded by an important international olive oil bottler and marketer (Simón Gari).

After a few years it is also acquired by Cía.

Internacional de Envases (Cidesa).

As manufacturers of crown corks – the popular “chapas” – two companies stand out:

(a) Tapón Corona Ibérico, a multinational originally from North America – Zapata Hermanos – which sets up major facilities in Leganes (Madrid) and.

b) Metalinas, another multinational of the same origin with two facilities – Bilbao and Getafe (Madrid) -; both develop quality products that reach great volume as a consequence of the increase in consumption of bottled colas and beers.

In Catalonia, Vem de Tapas Metálicas has developed as Cidesa’s main competitor in the manufacture of twist-off capsules and equipment for closing them on glass bottles.

Aerosols are gaining ground as a very practical system for the application of household and cosmetic products.

Metalinas also stands out as a manufacturer of these containers, then others join this market such as Cía.

Internacional de Envases.

They still use the tin-lead soldering technique although soon they will introduce the electric one.

This has led to the emergence of specialized companies to meet this need.

Thus, Cromometalicos in Catalonia, Manuel Alemán in Murcia, Metalcolor (Calahorra 1963) and Litalsa in La Rioja and Artiscar in Galicia are companies that dedicate themselves exclusively to this activity and reach maturity during this period.

The raw material – tinplate – is basically supplied by the two national steel mills: Altor Hornos and ENSIDESA. The first one has a long history behind it and by this time it manufactures “coke” type tinplate – obtained by immersion in tin bath – but by the sixties it puts on the market the “electrolytic” type which will soon be the only one since it has better properties.

(10) (To learn more about tinplate, we refer you to other sections of this Web).

ENSIDESA, on the other hand, is a recent iron and steel company that started manufacturing this product directly in the “electrolytic” type.

The needs of the market are completed with imported tinplate – almost all of it from European countries -, which is regulated by a series of measures (quotas, quotas, tariffs, temporary imports…) that make it a complex task.

This has led to the emergence of specialists in the form of warehousemen.

Gaskets and compounds for lids are supplied by Grace – an American multinational, the most important worldwide – based in Barcelona (11) and La Artistica – a family company – in Vigo.

Industrial containers use handles, glands, caps… Emilio Canudas and later Jacob Berg – both from Catalonia – are the main suppliers.

Monturas y Fornituras, also a Catalan company, specializes in aerosol valves.

The list could be much longer, even longer if we were to mention the manufacturers of varnishes and inks, but we leave it here so as not to make the story too dense.

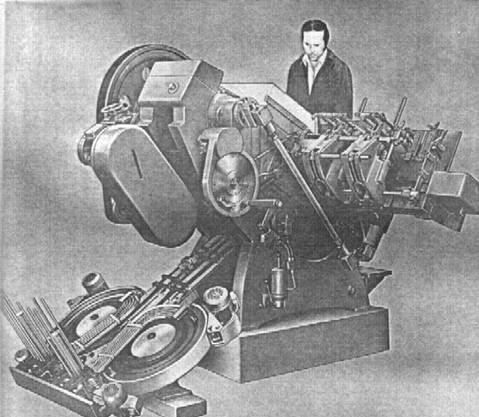

Low speed curling and gumming machine The number and importance of workshops dedicated to the construction of equipment is increasing. Thus, in addition to those already mentioned in the previous section, which are still active, others such as Ruibus (La Rioja) specialized in seaming machines or Escobedo y Gonzalvez – Alcantarilla (Murcia) – which offer a much wider range of products. In tooling, Talleres Varas (Badalona) began to stand out, which will consolidate over time as the best specialist in tooling and die-cutting for the sector (12) and Talleres P. Ezquerra in San Adrián (Navarra) focused on seaming machines. Not all the workshops that started up in this period managed to consolidate, for example Comec, which was founded by the Swiss engineer Frendich – who had a very good experience in the metalworking industry, having been the outstanding technician of Metalgrafica del Mediterráneo – and which tried to sell its products under the guidance of Manuel De Cepeda – another engineer who knew the sector very well, coming from the Echazarra trading company – did not manage to gain a foothold and ended up closing its doors, leaving a few dozen shears and some prototypes of notchers and other machines on the market. Soon after, M. De Cepeda tried again to create another national company that would follow the path initiated by Comec – manufacture of machinery and transport equipment – founding “Talleres Mara” in Madrid, but he did not manage to consolidate it either. Finally, in the nineties, he managed to get his idea off the ground by buying the company Cerlei – Oporto – in Portugal, a company with a long tradition in the manufacture of equipment. In these two decades, the manufacture of equipment for the varnishing and printing of tinplate in Spain is represented by Inghor – which builds continuous furnaces – and more humbly by Talleres Ruiz which builds and repairs varnishing machines; both installed in Vizcaya. At the beginning of this period, several metalworkers – mainly those who worked for the fish canning industry – promoted the creation of an employers’ association that would try to help solve the many needs of the sector and would be the voice of the sector before the State administrations and the different national and international organizations, as well as achieve a minimum coordination in social policy. This idea gave birth to the Asociación Metalgrafica Española (AME). From then until today, it has carried out a meritorious work in different fields, for example: as a member in forums where standards and regulations are defined: UNE, AENOR, Sefel, Euronorm…, in environmental policy, in labor relations, legal advice, etc…. Many are the people who have dedicated their time to a discreet but effective work and who are already part of the history of this association such as: Massó, De la Paz, Marín, Olivares and many others. To summarize, we could say that the 20 to 25 years that comprise the written period were very dynamic and expansive.

(3) Carnaud-Galicia counted on the contribution of two French engineers of great level, Chauven and Ledermat, who had been two great designers of “decogalle” equipment that had taken this technology to its peak of development.

During their stay in Spain, they turned this plant into the best level among those dedicated to fish packaging in France, Morocco, Algeria and other countries of the Carnaud group.

(4) Megasa belonged to the Rey family, which was committed to the task of setting up a company specialized in the canned fish packaging sector, closely linked to the seafood products of those coasts.

The Rey’s tried to evolve by offering at all times a quality product with the latest technology.

(5) Olmesa – OleoMetalgrafica del Sur SA – was created with the economic aid of the Plan Jaén – promoted by the government of the nation to improve the social conditions of this province – by the agrarian businessmen Francisco Lubian and Alonso Torres.

Their original plan was to produce canned olives, for which they decided to manufacture their own containers, but later they began to sell the cans they produced in their spare capacity and seeing that there was more demand in the market of containers than in that of canned olives, they transformed the facilities to dedicate themselves exclusively to the metallurgical industry.

Given the lack of qualified human resources in the area, they hired some Catalan technicians.

Among them, Juan Caballer stood out, a man of great experience coming from a metallurgical plant in Badalona, who laid the foundations of what would become a very modern manufacturing plant for his time.

Juan Caballer created a school, and his sons were the first to continue his trade.

Years later they would go on to other metallographic factories.

(6) As the development of Olmesa was very positive, F. Lubian and A. Torres decided to make a geographical and technological leap, deciding to set up a second factory in Levante. In order to obtain economic and technological participation they did not hesitate to travel to North America looking for a suitable partner, this seen in the context of Spain at the end of the fifties must be considered an authentic entrepreneurial feat. They managed to get Continental Can Co., world leader in the sector at that time, interested in their project and also to involve Metal Box – England – and Carnaud – France – in it. This project materialized in a new plant in Cuart de Poblet (Valencia) dedicated for the time being exclusively to vegetable preserves.

(7) The “twist-off” cap began to be manufactured in Spain in 1961 at the Olmesa plant in Linares (Jaén) and was the first license and technological support provided by Continental Can to this company.

When the Valencia factory – Cidesa – was inaugurated, the production facility for these caps was transferred to it.

From the very beginning, a young technician – Francisco Ascasibar – took part in this project, who would eventually become the main driving force behind the development of this type of end caps in Spain and later in Europe, always hand in hand with this company.

(8) The Sanchez Rex brothers were the creators of this company.

They acquired quite modern and fast equipment from Italy (basically Cevolani and FMI).

After a period of brilliant activity with an accelerated expansion from Murcia to the other two strategic points of vegetable preserves (La Rioja-Navarra and Extremadura), they entered a period of rapid deterioration.

Significant investments, a somewhat daring management and family problems – a traffic accident took the life of one of the key family members of the business – led to the bankruptcy of the company.

(9) Miguel Vivancos and his brother, well versed in the tinplate business, set up this company, which slowly but steadily consolidated over the years, until it became the main manufacturer of tin cans.

The strong personality of Miguel Vivancos was well known in the sector during the last third of the 20th century.

His delicate health and the absence of a young generation to take over, led to the sale of the family business at a high price on the international market.

Of course, the moment chosen for its sale was the last master stroke of this far-sighted businessman.

(10)

Fue muy meritorio el esfuerzo realizado por la Siderurgia nacional para modernizar sus instalaciones y emplear la más nueva tecnología mundial en la fabricación de hojalata.

Por estos años destaca la brillante labor de un técnico de Altos Hornos de Vizcaya, el ingeniero Joaquín Casado.

Bajo su dirección la fábrica de Echeverri puso en marcha importantes proyectos: Doble reducida, laminado en frió, recocido continuo, etc.

(11)

La expansión de Grace en el mercado nacional se llevó a cabo bajo el impulso de Francisco Garay, extrovertido gestor de la misma llegado de Norte América, de origen cubano, que se asentó definitivamente en España.

(12)

Jaime Varas estableció un pequeño taller mecánico que especializó en la construcción de matricaria, sobre todo en troqueles para tapas redondas y rectangulares.

La buena calidad de los mismos fue la baza que poco a poco le sirvió para incrementar su clientela, primero en las metalgraficas catalanas y después en toda España.

Su hijo Jaime y su yerno Franco Tamburini pronto ayudaron en el progreso del negocio y con el tiempo quedaron al frente de él.

Ampliaron las instalaciones y mejoraron las maquinas-herramientas llevando el Taller a una excelente posición en el mercado con trascendencia internacional. Alejandro Valderas View 2nd partBackto Miscellaneous World Cans

0 Comments