Millions of aluminum beverage cans and lids are manufactured around the world on a daily basis. This metal packaging is in high demand lately due to its versatility in terms of recyclability, easy to carry, extremely lightweight, good protector of UV-sensitive beverages, among other great attributes. That is why as a manufacturer of metal packaging is important to understand the metal forming processes that occur in a production line of aluminum cans 2 pieces, as it will give us the necessary knowledge regarding the transformation that the metal undergoes and thus be able to work on critical points of the forming process to finally get a good performance in the production lines.

Millions of aluminum beverage cans and lids are manufactured around the world on a daily basis. This metal packaging is in high demand lately due to its versatility in terms of recyclability, easy to carry, extremely lightweight, good protector of UV-sensitive beverages, among other great attributes. That is why as a manufacturer of metal packaging is important to understand the metal forming processes that occur in a production line of aluminum cans 2 pieces, as it will give us the necessary knowledge regarding the transformation that the metal undergoes and thus be able to work on critical points of the forming process to finally get a good performance in the production lines.

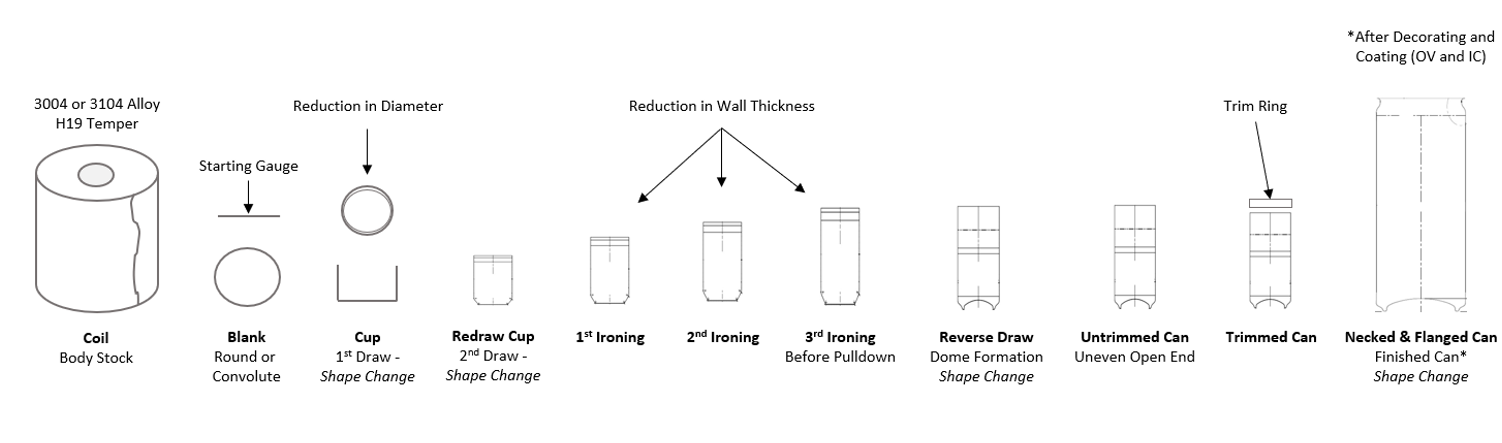

The aluminum coils (Alloy 3104 -H19) that arrive at the production plants will be transformed into aluminum beverage cans through a series of equipment and forming processes. The aluminum metal will travel from the Front End of the process to the Back End of the process between 1800 and 2000 cans per minute approximately, where it will be processed and formed by typically 20 machines until it is palletized, say about 45 minutes of manufacturing process from coil to finished can (C2C).

The aluminum coils are introduced to the production lines by means of the uncoiler, the foil flows to the lubricator and cupper press, where once placed in the cupper press it undergoes its first two transformation processes, cutting of the disc (Blanking Operation) and first drawing (Drawing Operation). The Cutting/Blanking operation is basically the forming of a disc that will contain the volume of metal necessary to form a can. The disc is cut and separated from the rest of the sheet by three tooling tools (Blank & Draw Die – Pressure Pad – Upper Cutedge). The Drawing operation takes place immediately after cutting, where the material continues to be clamped between two tooling (Blank & Draw Die – Pressure Pad) and is pushed by a Draw Horn through the Blank & Draw Die. These first 2 processes happen in a single stroke of the cup press, where the resulting product is an aluminum cup, 12 or even 16 cavities/cups per stroke.

There are several criteria during the design of the cup press tooling that must be respected, during the cutting of the disc is the thickness of the material (clearance between cutting tools), during the first drawing is the thickness of the material and the reduction in diameter of the disc where the reductions greater than the >39% become problematic with low thicknesses, low forming depths and gaps between tooling.

The cups are sent to the Bodymakers where they will be pushed through a series of dies. The metal transformation processes that happen in this machine are Redraw, Ironing and Reverse Draw, all in one stroke of the Bodymaker. The resulting product is a straight wall can (Untrimmed Straight Wall Can) which is then sent to the can trimmer. The re-molding process is simply a change of shape of the metal from cup to can, where again the material thickness (typically 0% reduction) and the reduction in diameter (typically <34%) play an important role in the tooling design.

The Ironing Process is where the metal undergoes a reduction in its original thickness, this typically happens in 3 Ironing Dies where the material is pushed and flows over the punch sleeve, to obtain the final dimensions of your body in terms of Mid Wall and Top Wall. The wall thickness reduction should be given in a balanced way between the first and second ironing die (e.g. 26-24%) and taking as a main criterion a reduction of less than 40% in the third ironing die. There are operations that use only 2 ironing dies with 1 redraw die (Redraw Die), basically because of the limited space in the Toolpack Cradle.

Once the can forming punch exits the ironing tooling, it meets the dome assembly where the Reverse Draw process will be performed. This doming process is simply a change of shape of the metal from a flat base to a dome, again the thickness of the material is important and the design of the tooling to allow the correct flow of metal to the area (Pull Down) and the proper forming of the base of the can. Since this area of the can has never been reduced in thickness, the dome area will retain the original thickness of the material.

During the following manufacturing processes after the body forming (say trimming machine, washing machine, printing machine, exterior and interior varnishing, drying and curing ovens), there is no metal forming process until you reach the Die Necker. The nesting process occurs through a series of diameter reductions in the mouth of the can, where through nesting stations the can is pressurized and its mouth is placed between Necking Die and Knockout punches to perform such reductions. It is a process of diameter reduction where the metal is subjected to compression, the uniformity in the thickness of the material and the conditions of the varnishes applied in this area play a key role since the clearance between tooling (Necking Die – Knockout) and its geometry do not change during production.

The last metal forming processes that occur on the production lines are flanging (Flanging Process) and if required reforming or reprofiling of the dome (Reform/Reprofile). Flanging is done through a rotary tool, where the can is pressurized and its mouth is placed and pressed axially against a Flanging head, in this process the metal is subjected to tension and takes the shape of the Flange Neck Rollers. Reshaping, which is the process typically used to increase dome reversion in a can (Buckle Strength), is nothing more than a notch is made in the vertical wall of the dome (Inner Transition Wall), the tool is ideally placed halfway up the vertical wall of the dome and the penetration or notch is made in the metal with an average gain of 8-9 PSI in dome reversion.

According to the above, it can be concluded that it is of utmost importance to know in detail all the metal forming processes that occur in a 2-piece aluminum can production line. A good quality cup will have a better chance of forming a good can and so on in this domino effect towards the end of the production lines. This good understanding will help us to produce high quality cans, increase efficiencies, reduce metal waste and increase production to supply aluminum cans in this new high demand.

i am interesting for one Automatic Aluminum cans production line.

Hello

Could you please provide price list for Automatic Aluminum Cans Production Line?

Thank you

is beverage line is different to hot aluminum juices can line

Please send more information on aluminium beverage can manufacturing and quality control