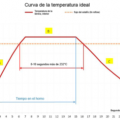

The release of electrostatic powder in the can after filling can be due to several reasons:

Overloading of the powder particles due to too high a voltage, which can cause the formation of waves (backpulverization).

Discharge of sparks into the dust layer, which can cause cratering.

Excess powder in the body of the can.

Change in internal suction or dust layer thickness.

If the vacuum is insufficient, the powder ducts and the application head may become clogged.

Change in the amount of powder sucked into the can body area.

Tearing of the powder coating on the ends of the can bodies.

It is important to keep in mind that these are possible problems that may arise during the can filling and sealing process. To solve them, it is necessary to carry out a proper control of the amount of dust and tension, as well as to make sure that the suction system is working properly.