In recent years, varnishes applied to tinplate for the manufacture of containers and lids have become increasingly important, as they are applied to most containers, both internally and externally.

Together with the continuous changes in European regulations, the analysis of varnishes and varnished tinplate (and E.C.C.S.) requires more and more attention from packaging manufacturers in order to meet the demands and requirements of customers and production processes.

All manufacturers have laboratories and methods and equipment to perform various analyses on this aspect, such as adhesion, flexibility, grammage, etc., but in many cases it is not known that most of these methods are standardized and in some cases with very up to date revisions.

We will therefore review the list of European regulations regarding this methodology and some other methods that could be considered for introduction into the quality control system or for the approval of new coatings.

PHYSICAL ENDURANCE TESTS

The physical resistance tests for varnished steel (tinplate and E.C.C.S.) are basically the following:

Adhesion.

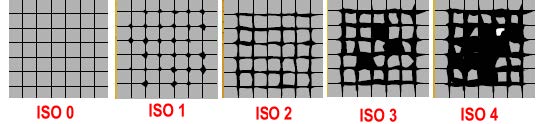

Adhesion can be evaluated by cutting the grating or by measuring tensile adhesion, and is covered by the following standards:

Standard UNE-EN ISO 2409 (June2021).

Paints and varnishes: Trellis shear test (ISO 2409:2020)

Standard UNE-EN ISO 4624 (October 2016)

Paints and varnishes: Tensile adhesion test (ISO 4624:2016).

Flexibility:

The flexibility of the coating can be measured by three different methods, which in some cases can be complementary, such as bending with a cylindrical mandrel, with a conical mandrel and by means of a drawing test, which are included in the following standards:

Standard UNE-EN ISO 1509 (April 2011)

Paints and varnishes: Bend test (cylindrical mandrel) (ISO 1519:2011)

Standard UNE-EN ISO 6860 (March 2007)

Paints and varnishes: Bending test (conical mandrel) (ISO 6860:2006)

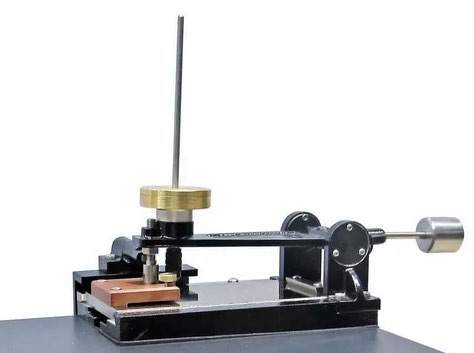

Standard UNE-EN ISO 1520:2007 (March 2007)

Paints and varnishes. Drawing test. (ISO 1520:2006)

The combination of the lattice cutting standard plus the deep drawing test on the same sample gives us an excellent adhesion test for the evaluation of material intended for deep drawing processes.

Surface hardness or scratch resistance.

The surface hardness test can also be performed by various methods, such as pencil hardness, durometer rod hardness, surface scratch hardness, as described in the following standards:

Standard UNE-EN ISO 15184 (July 2020)

Paints and varnishes. Determination of film hardness by pencil test. (ISO 15184:2020).

Standard DIN EN ISO 22557:2021-02

Paints and varnishes – Scratch test with spring pen (ISO 22557:2019);

German version EN ISO 22557:2020

UNE-EN ISO 1518-1/2 Standard (February 2020)

Paints and varnishes. Determination of scratch resistance. Part 1: Constant load method. (ISO 1518-1:2019).

Paints and varnishes. Determination of scratch resistance. Part 2: Variable load method. (ISO 1518-2:2019).

Standard UNE-EN ISO 2815:2003

Paints and varnishes: Buchholz indentation test (ISO 2815:2003)

Coating thickness or grammage –

The measurement of coating thickness (or applied grammage) is one of the most requested and necessary tests due to physical and chemical resistance and application cost issues and is included in the following standard:

Standard UNE-EN ISO 2808:2020 (October 2020)

Paints and varnishes. Determination of film thickness. (ISO 2808:2019).

The different methods for the determination of film thickness, both wet and dry, are described, ranging from the classical method by difference of weight to the more modern and faster methods of magnetic induction or eddy current.

Impact resistance:

This is the evaluation of a coating against shocks and deformations during the production and handling of containers.

Standard UNE-EN ISO 6272-1:2012 (January 2012)

Paints and varnishes. Rapid deformation tests (impact resistance). Part 1: Drop test of a mass with a large-area striker. (ISO 6272-1:2011).

All these standards, published by AENOR in Spain, and which can be purchased through its website in digital format, are collected in other countries and languages in their corresponding versions and by the different standards bodies in each country, AFNOR, DIN, British Standard, etc.

Other tests such as lubricity, porosity, etc. are not standardized, so tests should be performed according to experience and needs in each particular case.

CHEMICAL RESISTANCE TESTS

Chemical resistance tests are used to evaluate the interaction of the coating with the packaged products and with the external environment to which it will be subjected during the average life of the packaging.

As mentioned in previous articles (see MUNDOLATAS n° 8 March 2022), there are several simulating liquids to which coatings can be subjected in order to check their resistance to packaging. These methods, although of great validity, are not included in the standards and are therefore not included in this article. Beyond them, we can list the following evidence:

Resistance to organic solvents, resistance to water, resistance to saline environment, resistance to sulfurous environment, resistance to UV radiation (sunlight) and resistance to filiform corrosion. Except for the last two and the first one, the rest are carried out in a salt fog chamber, with prolonged exposure.

Standard UNE-EN ISO 11997-1:2018 (May 2018)

Paints and varnishes. Determination of resistance to cyclic corrosion conditions. Part 1: Humidity (salt spray)/dryness/dampness. (ISO 11997-1:2017).

Standard UNE-EN ISO 11997-2:2014

Paints and varnishes. Determination of resistance to cyclic corrosion conditions. Part 2: Humidity (salt spray)/dryness/humidity/UV light. (ISO 11997-2:2013).

Standard UNE-EN ISO 4623-1:2019

Paints and varnishes. Determination of resistance to filiform corrosion. Part 1: Steel substrates. (ISO 4623-1:2018).

Standard UNE-EN ISO 4623-2:2016.

Paints and varnishes. Determination of resistance to filiform corrosion. Part 2: Aluminum substrates. (ISO 4623-2:2016).

UNE-EN ISO 2810:2021 Standard

Paints and varnishes. Natural aging of coatings. Exposure and evaluation. (ISO 2810:2020).

For continuous band coating, the UNE-EN 13523 standards stand out:

Spanish Standard UNE-EN 13523-11:2020 (July 2020)

Metals painted in continuous band. Test methods. Part 11: Resistance to solvents (wipe test).

Spanish Standard UNE-EN 13523-23:2015 (October 2015)

Metals painted in continuous band. Test methods. Part 23: Resistance to humid atmospheres containing sulfur dioxide.

There are many other standards for the analysis and evaluation of varnishes in liquid state, affecting viscosity, density, dry extract (or volatile part), etc., which affect those who handle these products in their facilities and will be discussed in future articles.

0 Comments