Physical properties of easy open lids:

Easy open closures, also known as easy open closures, have several important physical properties that characterize them:

- Material: They are commonly manufactured in metal such as tinplate, TFS (Tin Free Steel) or aluminum. The choice of material may vary by region; for example, in the United States, aluminum is preferred, while in Europe, due to the high cost of energy, tinplate tends to be used more for full-opening covers.

- Dimensions: Cap dimensions are critical and are measured with tools such as gauges, comparators, micrometers, calipers and automatic gauges. Dimensional tolerances are very precise and can be in the range of 0.0X mm for certain parameters.

- Incision design: The lid has a peripheral incision in the central panel, with a depth of approximately 2/3 of the thickness of the material and with a triangular or trapezoidal profile. This incision is critical because it is through this incision that the central panel is torn for the opening.

- Ring: The lid has a ring for easy opening. This ring must fit exactly in the incision and not be lifted during the thermal process, being accessible to the finger.

- Rivet: The rivet holds the ring and is a delicate parameter due to the strong deformation it undergoes. It is important to avoid porosity or loss of watertightness.

- Corrosion protection: A protection or “repair” is applied to the incision to prevent corrosion. This is vital to the added value of the closure and is one of the best kept secrets of the manufacturers.

- Rubber: Rubber is applied to the inside of the lid flange to act as a sealant and ensure a tight seal. The weight, placement and residual moisture of the rubber are controlled.

- Coatings: The caps are protected internally and externally by varnishes, which can be colorless or gold-plated, to resist processes such as sterilization and prevent corrosion.

- Opening effort: It is designed so that the effort required to open the cover is moderate, with specific reference values.

These properties ensure that the easy open closure fulfills its function of providing a convenient and safe opening, while maintaining the integrity and tightness of the container.

Coating types for easy open:

Coatings for easy-open lids have the function of protecting both the inside and outside of the lid from corrosion and other types of deterioration. Internally, a varnish system is applied which must be secure to ensure that there is no porosity under the rivet or in the incision area. This area of the rivet is subjected to strong stretching and impact for the attachment of the ring, so the inner varnish must withstand harsh conditions. Interior systems can have gold or white shades and are generally composed of at least two different and complementary coatings.

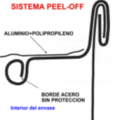

For some very special finishes, such as Peel-Off or Easy-Peel caps, a polymer film, such as polypropylene, is bonded to the metal. In addition, the possibility of applying more environmentally friendly and sustainable coatings, such as vegetable or biodegradable coatings, is mentioned, although it is not specified whether these are applied directly to easy-open lids.

It is important to note that the coatings must be compatible with the contents of the container and resist the process of container formation, as well as the heat treatments to which the container may be subjected.

Methods of cap analysis:

To analyze the caps in the context of quality control and product quality assurance, several methods are used, depending on the information provided:

- Collection and statistical analysis of the dimensional data of the covers: The data related to the dimensional parameters of the covers are collected and statistically analyzed, considering the dimensional tolerances of the product according to the approved drawing and technical data sheet (TDS). Statistical Process Control (SPC) software such as Minitab is used to perform capability studies.

- Verification of the characteristics of the sealing compound: A sample analysis is performed by a specialized third party to verify the quality of the application of the sealing compound on the caps. Analyses include visual check, sealing compound weight analysis, rubber radial distribution analysis and peripheral (octane) distribution analysis.

- Tightness tests: Different types of tightness tests are carried out in collaboration with a specialized external company to identify and assess the type of leakage of the containers.

- Attribute control: Checks are carried out on each sampling of caps, including evaluation of internal and external porosity, verification of dirt, bumps or scratches, and adhesion of the sealing compound.

- Measurements during adjustment: Parameters that do not usually vary during manufacturing or that have been adjusted to correct a defect or out-of-tolerance are measured, especially when there are format changes or line stops.

- Measurement of 100% of the containers/caps: It is performed on the production line itself in a non-destructive way, using automatic methods such as vision cameras.

- Measurement by sampling: A control plan is followed, and measurements may or may not be destructive, carried out by personnel and aided or not by automatic equipment.

These methods are applied to ensure that the caps meet the required specifications and to identify any deviations in the manufacturing process that may affect the quality of the final product.

0 Comments