Introduction

Metal containers are widely used in the food and beverage industry due to their preservation and resistance properties. A crucial aspect in the quality of these containers is the integrity of the double closure, which guarantees the tightness and protection of the contents. One of the common defects in double sealing is seam bumps, which can compromise the quality of the package and its contents. This white paper discusses in detail the seam bumps defect, its causes and possible solutions.

Defect Definition Seam Bumps

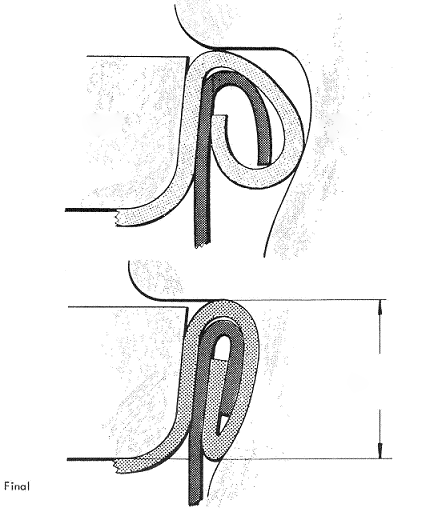

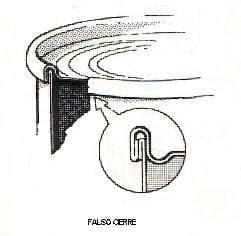

Seam bumps are defects that appear as internal protrusions in the seam of a metal package. These protrusions can affect the tightness of the closure, allowing air and contaminants to enter, compromising the quality and shelf life of the packaged product.

Causes of Seam Bumps

There are several causes that can generate seam bumps in metal containers. Some of the most common causes include:

2.1. Over-tightening the seam: Incorrect adjustment of the rollers in the second seaming operation can generate excess pressure, causing seam bumps and seam deformation.

2.2. Body hooks too long: If the body hooks of the container are longer than necessary, they may cause protrusions in the seam when interacting with the sealing compound.

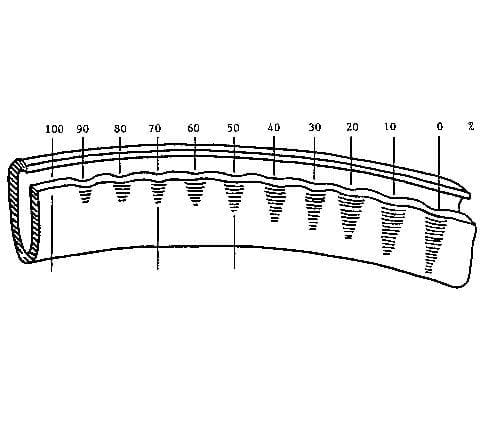

2.3. Excessive or uneven distribution of sealing compound: Excessive or uneven distribution of sealing compound can generate internal pressures in the seam, leading to the formation of seam bumps.

2.4. Combination of sealing circumstances + compounds: A combination of excess sealing compound, low closure height and high body and lid hooks can generate seam bumps.

2.5. Foreign matter inside the zipper: The presence of foreign particles inside the zipper can generate protrusions by interfering with proper seam formation.

2.6. Product filling temperature: Inadequate filling temperature can affect seam formation and generate seam bumps.

Solutions to Seam Bumps

To solve the problem of seam bumps, the following measures should be taken into account:

3.1. Check and adjust seamer settings: It is crucial to check and adjust the seamer settings, especially in the second seaming operation, to ensure proper tightening and to avoid seam bumps.

3.2. Check the length of the body hooks: Make sure that the body hooks are not too long and conform to the technical specifications of the package.

3.3. Check and adjust the quantity and distribution of the sealing compound: It is important to control the quantity and distribution of the sealing compound to avoid internal pressures in the seam that generate seam bumps.

3.4. Eliminate the presence of foreign matter in the closure: Ensure that there are no foreign particles in the closure that could interfere with proper seam formation.

3.5. Control product filling temperature: Maintain an adequate filling temperature to avoid problems in seam formation.

Conclusion

The defect of seam bumps in metal containers can compromise the quality and airtightness of the packaged product. It is essential to analyze and solve every possible cause of this defect in order to guarantee the quality and useful life of the product. The implementation of the solutions proposed in this white paper will contribute to improve the quality of the double closure and, consequently, the quality of the package and its contents.