SUMMARY

It describes tests carried out in the laboratory, with canned different vegetable preserves, carried out using containers with lids and funds from TFS, to see the behavior of the same before this material. It is concluded that this product is perfectly valid for this function.

INTRODUCTION

The chrome sheet, product known internationally as TFS (Tin Free Steel) and ECCS (Electro Cromium Coated Stell) began to be manufactured in 1961 in Japan as an alternative to conventional tinplate. Its consumption in the last quarter of a century has been increasing progressively, at the present time it represents approximately one third of the total steel consumed in the field of packaging.

The product consists of a steel base, identical to the one used to make tinplate, with a mixed coating composed of:

– A layer of metallic chrome, applied directly on the base steel from 50 to 90 mgr / m2.

– A layer of chromium oxides, on the previous one, of 7 to 15 mgr / m2. See figure nº 1

Figure nº 1: Structure of the chrome plate

A film of oil similar to that of tinplate is deposited on the aforementioned coatings, in order to prevent damage in the handling of the product.

The color of the chrome plate is bluish-gray metallic, with slight chromatic variations depending on the deposit of chromium oxides. This appearance can be varied by choosing the appropriate varnish to obtain the final look you want. The TFS presents an excellent adhesion to the varnish, which makes it an ideal material for embedded and re-packaged packaging and stamped parts.

The chrome plate has a resistance to corrosion comparable to the tinplate of coating 2.8 gr / m2. Due to the electrochemical behavior of chromium, it always acts to promote the dissolution of iron, therefore it is necessary to use the TFS varnished on both sides.

This material is declared harmless by the FDA (Food and Drug Administration) and similar organizations in other countries.

ANALYSIS

In the present work it is summarized:

– The studies carried out on the behavior of three-piece containers (caps and bottoms of chrome plate and body of tin) in different types of canned vegetables and their comparison with conventional tin containers.

– The verification of the degree of protection offered by different types of varnishes, applied in industrial lines, in the same preserves.

MATERIAL AND METHODS

The laboratory work was done with the following material:

Packaging : Bottles of format ½ Kgr. Ro 73 x 110. Tinplate tin bodies 11.6 / 5.8. Tapas and TSF funds

Varnishes :

For tapas and funds, 8 different varnish options were used:

-A Epoxyphenolic gold a pass.

-B Epoxyphenolic gold two passes.

-C Epoxyphenolic gold + Zn oxide

-D Organosol gold a pass

-E Organosol gold two passes

-F Organosol + Zn oxide

-G Organosol white

-H White porcelain P

In the bodies epoxyphenolic gold varnish was used for a pass, except in the containers called H, which was used porcelain.

Preserves :

The following vegetables were prepared directly in the industrial plant, without modifying the standard manufacturing process:

– Asparagus (sulfurous and unstable power)

– Spinach (unstable power)

– Leeks (sulfur power)

– Peeled whole tomato (acid detangling power)

Over 500 containers of each product were filled, with different types of varnish. Control samples were used in the amount of 1/3 of the total with conventional tinplate cover / bottom.

Each type of canned was divided into two lots:

1.- Storage at 55º C for 1, 2 and 3 months

2.- Storage at room temperature for 12 and 24 months.

We proceeded to make openings to the scheduled times verifying in each case:

– pH

– Porosity

– Presence of metals: Iron, tin and chrome

RESULTS

The results found for the four vegetable preserves under study, showed that the pH values found were normal for each product when they were kept at room temperature.

The storage system at 55 ° C implies a progressive decrease in pH over time. This is because the high temperature favors the dissociation of the organic acids. No preserved analyte of varnished containers presents significant chromium levels.

The hexavalent chromium present in the chrome plate is minimal, in addition the food was not in direct contact with the chromium nor with the chromium oxides since varnished containers were always used. Anyway, it should be noted that if part of the hexavalent chromium had passed into the food, it would have had enough reducing capacity to transform it into a trivalent, non-toxic state.

2 years were established as storage time at room temperature, as it is the period of time from which different behaviors of the different packages are detected, if any. For all the products that were included in this study, it was observed that the iron content was the parameter that best differentiated the behavior of the different tinplate and TFS varnishes. The average porosity, on covers and bottoms, revealed that the influence of the type of varnish is greater than that of the material or the material / varnish interaction. In all products, the varnish that showed the poorest behavior with respect to porosity was epoxyphenolic gold in one phase.

A.- Canned asparagus

Table No. 1 shows that varnishes with zinc oxide (epoxyphenol and organosol) have the best performance in relation to iron content, which is the element that showed the greatest variability in all preserves. No significant differences were detected between these varnishes with both materials, TFS and tinplate. However, the behavior of tin containers was somewhat better than those of chrome plate in practically all the varnishes used in that study, although their differences tended to diminish over time.

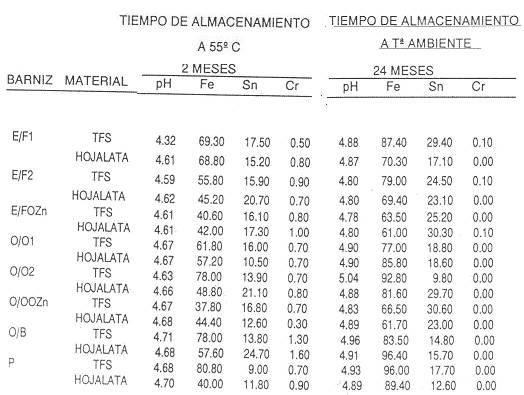

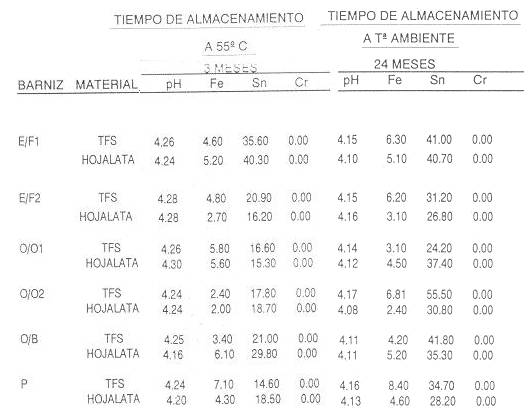

Table nº 1: pH and content in metals (ppm) in canned asparagus

It should be noted that when varnishes with zinc oxide were used, the amount of iron released to the medium decreased considerably. This was produced by the chemical reaction of the sulfur compounds of the asparagus with the zinc oxide, forming zinc sulphide and preventing iron from being released in the porosity zones. The iron content after three months of storage at 55 ° C was less than two years at room temperature. See table nº 1.

Regarding tin, the maximum levels found were low and therefore did not give rise to differentiation between varnishes and materials.

In the direct visual assessment, once the containers were opened, a better appearance of the tin covers and bottoms was observed than those of the TFS. Corroborating this assessment, it was found that the lowest porosity values found were when the porcelain varnish was used on tinplate but also with the organosol gold varnish with zinc oxide.

B.- Canned spinach

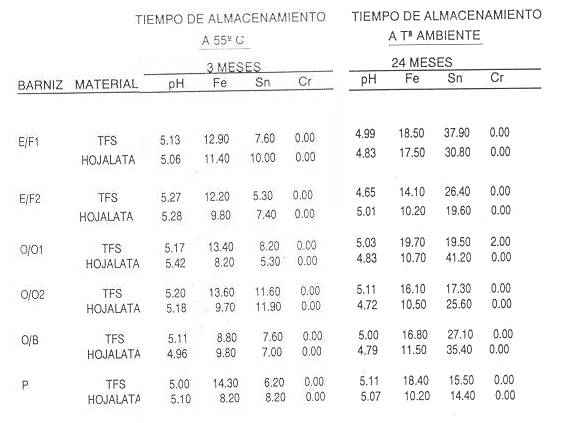

In the tin containers, the iron content was lower than in the chromed sheet, after 2 years of storage at room temperature. See table nº 2. In the case of tin, the containers with epoxyphenolic varnish of one pass gave the highest values of iron. In contrast with the TFS, all the varnishes showed a very similar behavior, although those that were applied in two passes, offered greater protection. Iron levels found after 3 months at 55ºC were slightly lower than those at 2 years at room temperature.

Table nº 2: pH and content in metals (ppm) in canned spinach

The porcelain varnish used was the one that presented the best response regarding the release of tin, for the two materials. It was also this varnish that gave the best values of porosity

Regarding the visual aspect, the covers and bottoms made with tinplate presented better presence than those of chromed sheet.

C.- Preserves of leeks

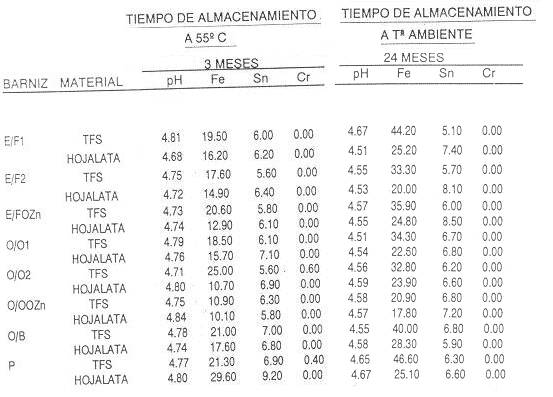

In the chromed sheet, the iron content was higher than in tinplate. Since the leek is a sulfur product, the varnishes that offered the best behavior were those that carried zinc oxide in its composition. The iron content in preserved leeks kept for 3 months at 55º C is less than 2 years. See table nº 3.

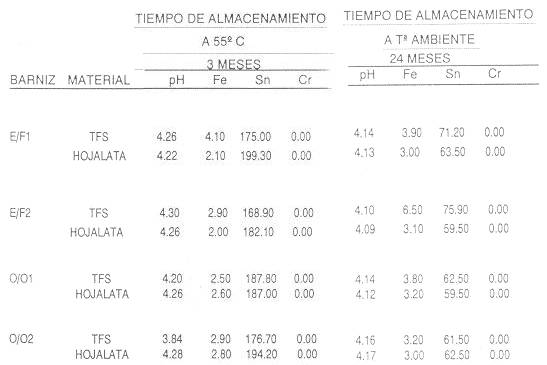

Table nº 3: pH and content in metals (ppm) in preserves of leeks

The levels of tin detected in these preserves were practically negligible in all the varnishes and in the two materials. It also presents a similar appearance both materials in terms of visual inspection. The lowest levels of porosity were found with the organosol gold varnish 2 passes and gold organosol with zinc oxide.

D.- Preserves of tomato

a.- Varnished containers: Their iron content is very small and corresponds to the levels of iron provided by the vegetable product. With the passage of time, no evolution of this metal was observed in the product, so the tomato did not show aggressiveness against the containers. This behavior was similar in the containers with covers and bottoms TFS as in those of tinplate. See table nº 4.

Table nº 4: pH and content in metals (ppm) in canned tomato in container with varnished body

There was a slight tin solution with the passage of time, never exceeding 50 ppm after two years at room temperature.

The appearance of covers and bottoms is very similar with both materials although it seems slightly better in tinplate.

b.- Bare containers: As in the previous case, the iron content in both tinplate and TFS corresponded to that of the product itself. See table nº 5.

Table nº 5: pH and content in metals (ppm) in tomato preserves in a container with a naked body

The content of dissolved tin was high, coming from the body of the container. These amounts are practically equal to 1 month at 55 º C than at 24 months at room temperature.

The appearance of the covers is identical in the two materials, no corrosion defect was observed. In the backgrounds, the epoxyphenolic varnishes of 1 and 2 passes on chromed sheet, were evaluated as those of worse behavior although without being rejected by them.

FINAL SUMMARY

1.- In all the products studied, the iron content was the parameter that best differentiated the behavior of the different varnishes in TFS and tinplate.

2.- In all the preserves, a somewhat higher iron concentration was observed in the containers with TFS than in the tin containers.

3 .- The migration of iron from the container to the product was higher in asparagus followed by leeks, being very light in spinach and inappreciable in tomato.

4.-No significant canned chrome levels were present in canned containers.

5.-In the case of preserves of sulfur products (asparagus and leeks) the varnishes that showed the best behavior were those that carried zinc oxide in their composition.

6.- The different varnishes exerted a similar protection for both the chrome plate and tinplate in the spinach and tomato preserves.

7.- In no container was observed bulge of chemical type during storage at room temperature and 55º C.

8.- As a final summary, the containers with chromed sheet, properly varnished, can be used as alternative validity to tin containers, fulfilling all the technical and sanitary requirements .

0 Comments