Design of a matrix for aerosol domes

- Material analysis: The first thing to do is to analyze the mechanical properties of the tinplate you will use, such as tensile strength, elongation and yield strength. This will help you to understand how the material will behave during the stamping process and to select the right parameters for the die.

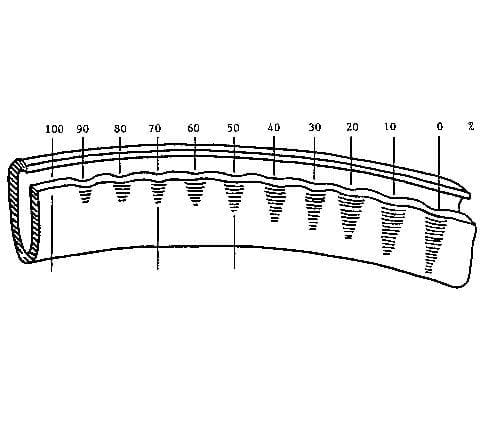

- Dome design selection: Choose a specific design for the spray dome, taking into account factors such as height, diameter and shape. You may want to research existing designs on the market to get an idea of current trends and consumer preferences.

- Die design: Design the die using computer-aided design (CAD) software, such as SolidWorks or AutoCAD. The die should include all parts necessary to form the dome, such as punches, dies and clamping devices. Make sure that the die dimensions match those of the selected dome design and take into account the thickness of the tinplate.

- Selection of stamping parameters: Based on the material analysis and die design, select the appropriate stamping parameters, such as stamping speed, applied pressure and lubrication. These parameters are crucial to ensure a successful stamping process and to avoid defects in the aerosol domes, such as cracks or wrinkles.

- Die fabrication and assembly: Once you have completed the die design and selected the stamping parameters, it is time to fabricate and assemble the die. You can do this using precision machine tools, such as CNC milling machines and lathes. Make sure that all die parts are properly aligned and adjusted to ensure a smooth and efficient stamping process.

- Testing and adjustment: Performs tests with the die to verify whether it produces high quality, defect-free aerosol domes. If you encounter any problems, such as cracks or wrinkles, adjust the stamping parameters or make changes to the die design as needed. Repeat this process until you are satisfied with the results.

- Mass production: Once the matrix is tested and adjusted, you can start mass production of the mm thick aerosol domes.