For the printing of 2-piece cans, today we have dec- orators full of accessories and enough technology to produce over 2000 cans per minute.

In this article we comment on the importance of maintaining a well controlled process to provide the conditions for this equipment to have an excellent diet and to achieve maxi- mum performance.

There are several factors that can negatively influence the performance of the decorator, but below we will comment 4 that we consider fundamental.

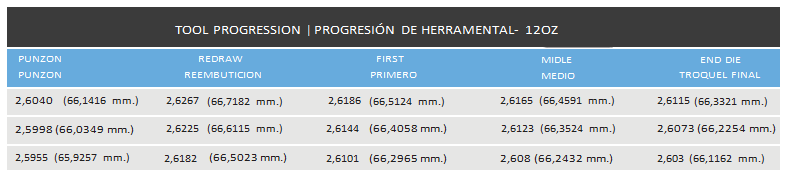

The progression of the tools with respect to the Chuck Diameter of the decorator.

We consider that it is a primary and ex- tremely important factor to have ex- haustive control over the grinding of the BodyMakers Punches since the decorator chucks and their respective diameters are estab- lished based on the progression of the Bodymaker tooling and the average value of punch diameter.

In the example below, we have in blue the punch with the largest diameter and then its grinding pro- gression for the 12Oz aluminum can.

This table is an example, each can maker has its own progression.

As we grind the punches to reuse them, the diameter is lost, so we must be very careful and respect that mini- mum limit recommended by the manufacturer, specifi- cally, it would have a gap of 0.022“ (0,5588 mm) between the diameter of the chuck with the smaller punch, below These measures significantly decrease the diameter of the can and you will have difficulty inserting the can into the decorator’s chuck.

Cut / Trimmer fault.

Sticking with the Bodymaker, we still have to consider trimming the can.

The trimmer is the team responsible for cutting the can and bringing it to a standard height there are several models of trimming equipment that basically work in this way: Feeding system, transfer, can holding chucks, fault system cutter head, vacuum system to hold can when trimming, scrap catch hopper and outlet hopper.

The cut is done by reusable flat discs or by blades housed in the head assembly and are available in hard metal or steel.

A faulty can can cause some inconvenience to the operation of the decorator and other downstream equipment.

The main problems can be blocking of cans in the single row while they are being trans- ported, feeding of the decorator, Displacement or retention of the can in the feeding with respect to the chuck of the machine and blocking of the can in the exit of the furnace at the tunnel track.

These inconveniences greatly affect the performance of the equipment generating high deterioration and 5S of the sector.

Cans with little mobility

As for the washing machine, in general we must consider that the can is in its best washing aspect and with good mobility. For this we have to follow the basic principles of the washing process, which would be chemical washing, mechanical washing, Exposure time (Speed) and temperature.

Its purpose is to remove organic and inorganic dirt, trea- ting the surface of the can, applying mobility intensifier and drying the can.

There are a series of parameters to follow and we must be very attentive to all the controls and verifications ca- rried out on this equipment, any deviation of these variables can directly affect the following processes, mainly the decorator.

The last stage, which would be the application of the product that makes the can mobile, is extremely impor- tant since this product helps the can dry and conditions it so that it fits well into the decorator’s chuck.

One pattern that follows is a 16 to 20 degree tilt on the Til Table. This equipment measures the angle at which a can slides in friction with two other cans and gives you an angle of mobility, cans with mobility greater than 20 degrees are already an alert and are considered a problem to feed your decorator.

Modulation of conveyors

Another very important aspect would be the mo- dulation of transports.

This adjustment has to be done very well, exceptionally, since it will guarantee that the can travels the en- tire path of the conveyors, following the modulation logic without pressure or overturning and that, as a consequence, rubs between the cans themselves, damaging each other.

ANDRE MALTA

Asesor de Mundolatas

Mundolatas Advisor

0 Comments