Why is it important that oxygen does not penetrate the container after packaging?

The importance of not allowing oxygen to penetrate the package after packaging is that the presence of oxygen can cause oxidation and deterioration of the packaged product, as well as the possible proliferation of aerobic microorganisms that could compromise the safety and quality of the food. Oxidation can adversely affect the organoleptic properties of the product, such as flavor and color, and reduce its shelf life. In addition, oxygen can react with certain food components and generate undesirable compounds. For these reasons, it is crucial to ensure an airtight seal that prevents oxygen ingress after packaging, especially in products that undergo sterilization and require a long shelf life, as is the case with canned food.

Are there microbes inside the package after packaging?

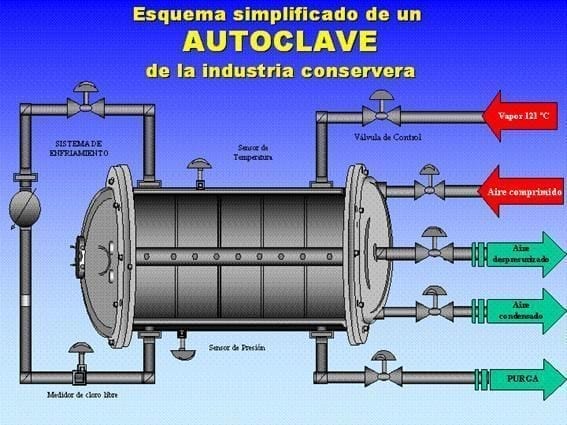

No, if the packaging and sterilization process has been carried out correctly, there should be no live microbes inside the package after packaging. Sterilization processes, such as heat treatment in autoclaves, are designed to destroy microorganisms that may be present in food, including spores of bacteria such as Clostridium botulinum, which can cause botulism. However, it is important that cans are dried as soon as possible after processing and that conveyor surfaces and equipment are thoroughly cleaned and disinfected to avoid recontamination. In addition, measures should be taken to prevent damage to containers during handling and storage that could compromise airtightness and allow microbial entry.

how can a metal container be contaminated?

A metal container can become contaminated in several ways during its manufacture and use. Some of the forms of contamination include:

- Corrosion: This can occur when unprotected areas of the container come into contact with corrosive substances such as acids (e.g. from acidic fruits, artichoke, pickles, vinegar) or chlorides. Corrosion can be more pronounced in areas of concentration and in areas that are not protected, such as the easy-open lid incision, closures and side seams.

- Contamination during filling: If liquids are spilled during the filling process and proper cleaning is not performed, contamination of the autoclave or cooling tank may occur. In addition, contamination can occur if the can washing system is inadequate, which can leave saline residues that create hygroscopic spots and spot corrosions.

- Contamination due to leakage: After heat treatment, if the hermetic seals are damaged or if there are failures in the closure, contaminating substances may leak into the interior of the container. It is important to keep all surfaces that come into contact with the containers clean and disinfected to avoid this type of contamination.

- Interactions between the food and the container: There may be migration of components from the container to the food that may alter its organoleptic characteristics or produce toxic effects. There can also be sorption, where the packaging absorbs food components, or permeation, where the packaging allows external contaminants to seep in.

- Mechanical damage: During transport on the packaging line, the use of abrasive metal surfaces or connections between chains can damage the varnish protection of the packaging, which could result in contamination.

- Damage during closure of the container: The varnish layer protecting the lid can be removed by abrasion during machining of the closure, especially if there is over-lubrication, under-lubrication or over-tightening of the closure.

To avoid contamination of metal containers, extreme care in their handling, proper maintenance of machinery and production lines, and a design that minimizes the possibility of damage and contamination are essential.