To solve corrosion problems on metal containers during the sterilization process in autoclaves with water drizzle, several key aspects must be considered:

- Water quality: The water used for both the thermal process and subsequent cooling must be treated to avoid the presence of organic matter and, above all, microorganisms that could contaminate the canned product.

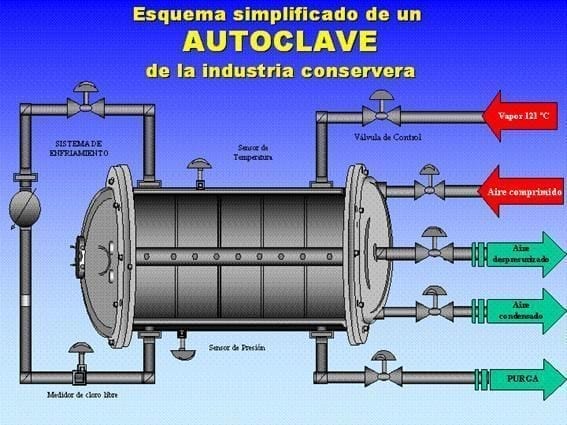

- Autoclave design: Conventional autoclaves and direct steam pasteurizers should have drains or bleeders at the bottom of the equipment to constantly eliminate the condensate that is generated and prevent it from accumulating and reaching the cans.

- Control of pH and salts: It is advisable to control the aggressiveness of the water by evaluating the Langelier or Ryznar index to avoid both corrosion and salt deposition on the containers.

- Avoid Boiler Condensates: Automatic condensate drains should be placed in the steam pipe downpipes, immediately before entering the boilers and autoclaves, to avoid alkaline condensates from the boilers.

- Use of Corrosion Inhibitors: Corrosion inhibitors can be added to the sterilization water or cooling equipment to protect the containers.

- Internal Varnishing: The best solution to avoid or reduce the destabilization of cans by aggressive foods is internal varnishing. The thickness of the coating is crucial and must be adjusted according to the aggressiveness of the packaged product.

- Proper Cleaning and Drying: After closing the containers, it is advisable to wash the cans to remove product residues and not to contaminate the water of the sterilization process. In addition, the cooling rate and final temperature must be controlled to prevent the containers from remaining wet for longer than is desirable.

- Inert Materials: The materials of the baskets, separators and autoclave must be inert to corrosion so as not to contribute to the problem.

By following these recommendations, the risk of corrosion in metal containers during the autoclave sterilization process can be significantly reduced.

why the edge of the lid of my metal cans get corrosion during autoclave sterilization?