A peel-off closure is a type of closure used on metal containers that allows a complete and simple opening of the container without the need for additional tools. Technically, it is characterized by the following manufacturing steps:

- Circular/Shear Cutting: Circular pieces of metal are cut to serve as the base for the lid.

- Basic lid: The pre-cut circular piece is processed in a similar way to the easy-open lids. This involves giving it the necessary shape and characteristics to become a basic lid.

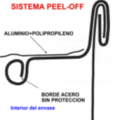

- Ring making and curling: A ring is created in the closure and a process known as curling is performed, which consists of folding or rolling the edge of the closure to form an airtight seal when applied to the container.

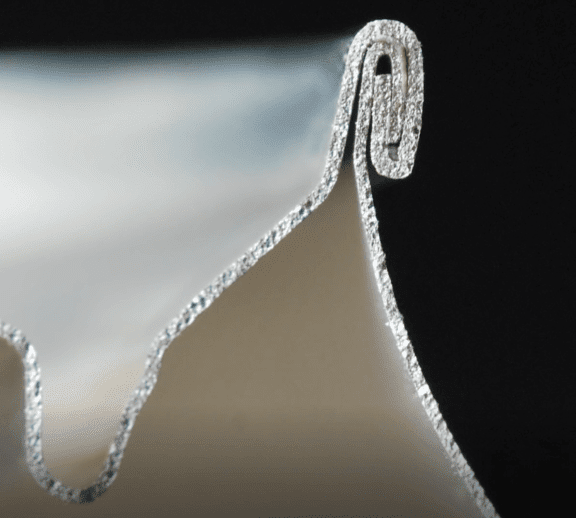

- Foil sealing: An aluminum foil or foil is sealed to the lid, which will act as a barrier to preserve the contents of the container and allow peel-off opening.

- Palletizing: Finally, the caps are organized and stacked on pallets for distribution and use on the packaging line.

Some technical aspects to consider in the manufacture of peel-off caps include:

- Overall dimensions: Must meet size and shape specifications to ensure proper fit with the container.

- Foil: It must be able to open without tearing and withstand the complete manufacturing process and use. The opening stress and burst test are checked, as well as the quality of the seal.

- Rubber: A sealing compound is applied to the inside of the flange to ensure tightness.

- Coatings: Outer coatings should be heat sealable and suitable for food contact, often containing polypropylene.

- Tightness: It is crucial that there are no discontinuities, pores or scratches in the exterior varnish that could compromise the tightness of the cover.

- Attributes: The visual appearance of the cover is inspected for stains, scratches, pores or bumps.

- Resistance to customer processes and products: Peel-off closures do not withstand as much pressure as other types, so packaging processes must be less aggressive and care must be taken with very aggressive products.

Common defects in the manufacture of peel-off caps can include oxidation in the curling, sealing defects, peeling of the polypropylene film, and wrinkling or deformation of the foil.

0 Comments