The lifting of the tabs after sewing in the process of using peel-off film ends (peel-off cap) could be due to several factors.

Mostly it would be due to the contact of the lip of the mandrel at the moment of making the double seam on the cans.

It could also be related to the parameters of the heat sealing tongs. If the temperature and pressure are not set correctly, they could affect the sealing process and cause the tabs to lift.

Another possible reason could be problems with the adhesive silicone used to glue the tab. If it is not applied correctly or is of poor quality, the tab may not be properly secured and may lift off after sealing.

In addition, the problem may be related to quality controls during the pressing process. For example, if the TEAR-OFF OPENING STRESS and MEMBRANE BREAKING PRESSURE values are not checked regularly and accurately, this could result in a defective product.

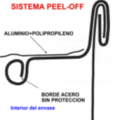

In addition, the problem could be due to defects in the aluminum membrane or to rubbing or machining marks. If there are any problems with the position or tears in the aluminum membrane, it could affect the sealing process and cause the tabs to lift.

It is also important to check that the film sleeve shrink wrap is correctly positioned and that the number of ends/sleeves is checked at each production shift.

Remember that these are potential reasons, and the exact cause can only be determined by a thorough examination of the process and products.