It describes several packing systems of lids / funds for internal use or for the canning, detailing the materials to be used and their characteristics.

INTRODUCTION

We have already published a paper on the different ways used in the industry to pack empty containers. See “Packaging of packages”. Now we complete this information, treating the same topic but for covers / funds, both those used by the metal and the packer.

The covers and bottoms require a suitable packaging, since its use is not possible directly and immediately in the production line of the container, that is to say as it leaves its manufacturing installation, since the compound deposited in its wing requires a time of rest to finish eliminating the residual humidity and its vulcanization. On the other hand, at least 50% of the production goes to the canner, and therefore will be deposited for a certain period in the warehouses and will travel together with the empty containers.

It is therefore necessary to protect the covers and bottoms by means of a wrapper that protects them from dust, dirt, damage during storage, transportation and subsequent handling. For this, the most used means is to use special bags, which once filled are stacked on pallets for easy handling.

PACKING CLASSES

These bags should allow “transpiration”, that is, the elimination of residual moisture from the funds through them. Therefore, they can not be totally hermetic. Hence, they are made of two different materials:

– Retractable micro perforated plastic. Its small holes allow moisture to escape. We will not enter is the description of a installation of packing of funds for not being the objective of this work, suffice to say that once filled the bags, are subjected to the action of a source of heat, which generates the shrinking of the same, giving a certain tension and rigidity to the whole. This method is imposed on the market

– “Kraft” type paper. In this case the moisture is removed through the paper. Once closed the bag is sealed with adhesive tape.

Figure 1 shows a finished pallet of packed covers / bottoms. It is appreciated that it is formed by:

– A wooden base or pan, where the bags are deposited, which allows their manipulation.

– A certain number of bags placed horizontally, forming a series of batches or floors. To give it a certain stability, when it comes to round covers / bottoms, the bags are placed in a quincunx, see figure # 1.

– Some paper bands, which embrace the bags on each floor and transmit to the whole a solidity sufficient for handling and transport without having to resort to the strapping of the pallet. Later we will return on this particular.

Figure No. 1: Example of palletized tray pan

The information on the different items used in the package of caps that we give below is valid indistinctly for any of the two bags indicated, unless we indicate otherwise.

PALET

The balet or pallet used for lids, is smaller in area than the one used to palletize containers, although it is intended that the dimensions of the first are approximately fractions of the second, so it is easier to use the means of transport. It is normal for two pallets of lids to occupy the same area as one of containers.

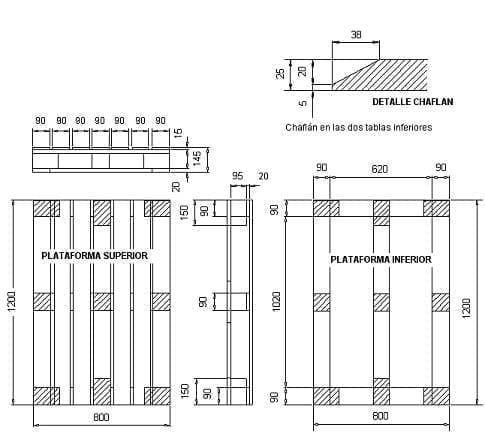

A pallet used for this purpose is the one indicated in figure 2, with dimensions of 1200 x 800 mm, although the ones measuring 1000 x 700 and 1000 x 540 are also widely used.

Figure nº 2: Special bale for palletizing lids

Manufactured of wood, it can be of the “two entrances” type, made by its larger side or “four entrances”. Must meet a number of conditions for employment to be efficient:

– The wood is usually pine, brushed, free of important irregularities

– Its maximum moisture content will be 18%. This prescription is important for a double reason: Do not transmit moisture to the lids and avoid subsequent deformations in the wood when it dries, they would produce a lack of stability in the whole.

– It is advisable that the wood used is free of oils, pitches or other products with characteristic odor, since they can transmit this odor to the containers.

– It is advisable to use propeller pitch – or “Solomonic” – points in its construction. Although its cutting costs a little, it compensates for a longer life of the pallet by avoiding the loosening of boards during use.

The pallets are reusable, therefore they are returned to the supplier.

BAGS

As we have already said, they can be made of:

- Paper: “Kraft” paper is commonly used, with a grammage of 75 to 80 g / m2. Its diameter is linked to that of the lid, although for tapas that differ in a few millimeters, the same bag can be used. Its length depends on the width of the pallet

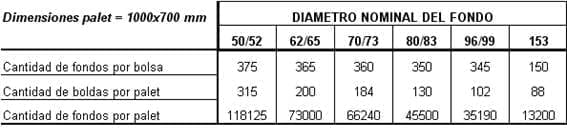

Table No. 4 reflects the amount of funds per bag, according to the diameter of the same, as well as the bags per pallet and the total amount of funds / pallet. All this for a specific case: pallet 1000 x 700. The quantity of covers / bag varies fundamentally due to the small differences in the height of the curl of the different diameters. The length of the bag coincides once filled with the width of the pallet except for bottom 153, which due to its high weight is packaged in smaller bags, so that they are manageable. In the latter case, two bags fit in the width of the pallet.

Table nº 3: Amount of funds per bag and pallet according to diameter

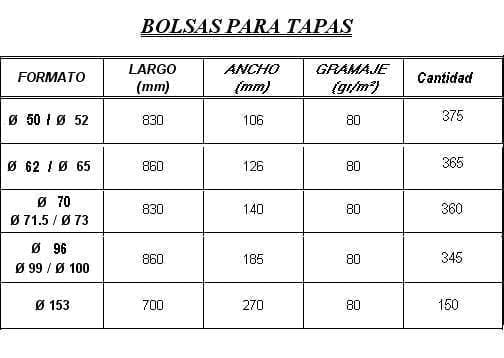

The dimensions of the paper bags to contain the amounts of funds indicated above, are reflected in table No. 4, as well as their grammage. The bags can be made of the “bellows” type or without it. Those indicated in table No. 4. are of the second type.

Table nº 4: Dimensions of paper bags for funds

- Plastic film In this case, the bag is made from heat-shrinkable film. There are teams that perform this operation automatically starting from coils of the micro-perforated film. The machine counts the preselected number of caps, takes the amount of film necessary to build the coil and wraps the caps in it, forming the corresponding roll. Then it is passed through a small oven that retracts the film, giving it enough rigidity. It is also possible to do the operation with manual means.

As for the quantities of lids to be put per roll, pallets to be used, etc. what is already indicated for paper bags is valid.

PAPER BANDS

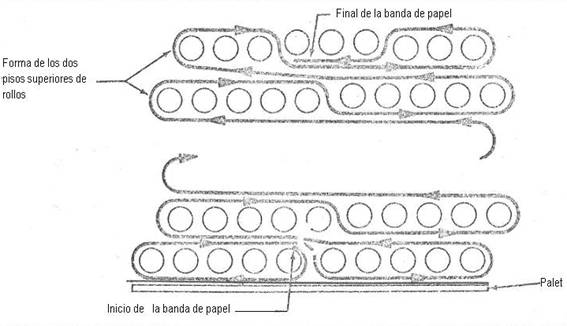

To shape the pallet of tapas and a good degree of firmness, Kraft paper bands are used to hug each floor of rolls. Figure 5 shows how to place these bands. Its start is positioned in the middle of the first round, embracing half of it, returning to starting point to embrace the other half. The top, at the top of the pallet, is affirmed by the central rolls of tapas. See course of the band in drawing n 5.

Figure nº 5: How to place the paper bands

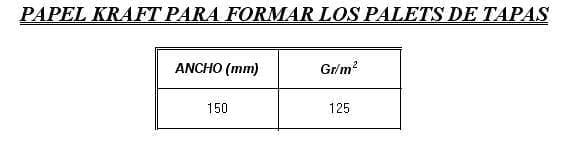

The characteristics of the paper used are indicated in table 6 for a design as indicated in figure 1, that is, with two paper bands located at 1/3 of the height of the bags. This system is solid enough for transport and storage under normal conditions. If the transport is very short and simple, you can even replace the two bands by a single center of double the width, ie 300 mm.

Table nº 6: Characteristics of the paper band for fixing the bags on the pallet

For very severe transport conditions, it is convenient to cover the pallet with a cardboard cover and strapping the whole. This way we guarantee the good functioning of the system. See figure # 7

Figure nº 7: Palet de tapas prepared for difficult transport

Of all the material used in the packaging of lids, only the wooden pallet and the cardboard covers are reusable, if the latter are required.

Sometimes, for internal use in the metal factory, paper bags can be reused. Sometimes wooden boxes are used to store the lids for internal use, regardless of the bags. This system is not very recommendable if the storage is prolonged, because the covers get dirty of dust.

0 Comments