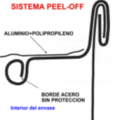

The technical process for the manufacture of a traditional closure is not explicitly detailed in the information provided. However, I can infer some general aspects of the metal closure manufacturing process based on the information on easy-open and Peel-Off closures.

The manufacturing process of a traditional cap could include the following general phases:

- Cutting circles: Using shears, metal discs are cut to the appropriate size for the cover.

- Formation of the basic lid: The cut discs are molded to form the outline of the lid, which includes the central panel and the flange or skirt that will allow the closure with the body of the container.

- Application of coatings: Lids may receive a layer of varnish or coating to protect the metal and prevent corrosion, as well as to ensure compatibility with the contents of the container.

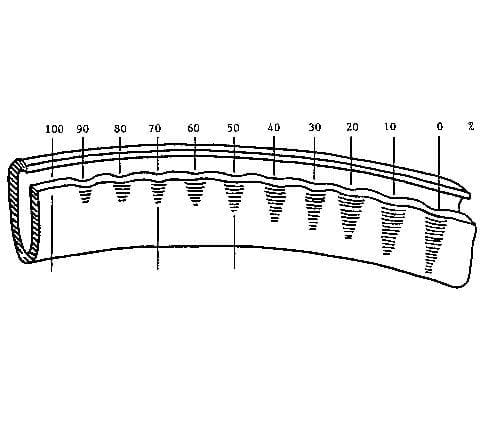

- Bending and forming: Bending operations are carried out to shape the skirt of the lid, which will later be joined to the body of the container.

- Gumming: A rubber or sealant is applied to the inside of the flange during the manufacture of the cover, which will act as a sealant to ensure the tightness of the seal.

- Palletizing: The caps are grouped and palletized according to the specifications of the production order for storage and/or transport.

It is important to mention that the traditional lid does not include easy opening features, such as rings or Peel-Off opening systems, and its opening generally requires the use of an external instrument such as a can opener. In addition, the manufacturing process may vary depending on product specifications and the machinery used by the manufacturer.

0 Comments