Introduction:

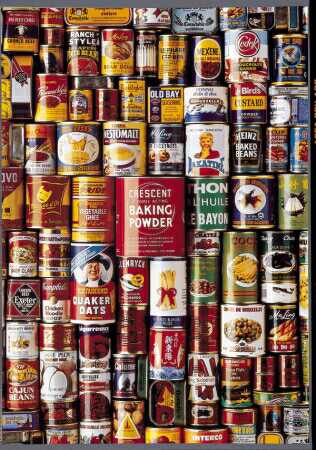

Can decoration plays a crucial role in improving the visual appeal and brand recognition of beverage cans. This article aims to provide an overview of can decorating techniques and the machinery involved in the process. By understanding the different decoration techniques and machinery used, manufacturers can create eye-catching designs and meet consumer demands.

- Direct printing:

Direct printing is one of the most common can decoration techniques. It consists of printing the design directly on the surface of the can using specialized printing equipment. The printing process generally includes prepress preparation, ink selection, color matching and print registration. Advanced direct printing technologies, such as UV curing and digital printing, have revolutionized the industry by offering faster production speeds and higher print quality. - Labeling:

Labeling is another popular can decorating technique that involves applying adhesive labels to the surface of the can. Labels can be made of various materials, such as paper, plastic or metallized films. The labeling process includes label application, positioning and smoothing to achieve a seamless appearance. Labeling offers versatility in design and allows for easy customization and branding. - Shrink sleeve:

Shrink sleeve decoration involves applying a plastic shrink sleeve to the can. The sleeve is designed to conform to the shape of the can when heat is applied, creating a seamless and visually appealing decoration. The heat shrink sleeve technology allows 360-degree graphics and enables intricate designs to be applied across the entire surface of the can. - Embossing and sinking:

Embossing and sinking are techniques used to create raised or sunken designs on the surface of the can. Embossing elevates design elements, creating a tactile and visually appealing effect, while sinking creates a depressed or raised design. These techniques add texture and depth to the can, enhancing its overall appearance and brand identity. - Coating and varnishing:

Coating and varnishing techniques involve applying protective coatings or varnishes to the can surface. These coatings provide a gloss or matte finish, improve durability and protect the design from fading or scratching. Coatings can also be used to create special effects, such as metallic or textured finishes, adding a premium look to cans.

Machinery used in the decoration of cans:

- Can decorating machines:

Can decorating machines are specifically designed to automate the decorating process. These machines incorporate various modules, including printing units, labeling stations, shrink sleeve applicators, embossing/sinking units and coating/varnishing systems. They ensure accurate and efficient decoration while maintaining high production speeds. - Prepress and design software:

Prepress and design software is an essential tool for preparing and optimizing artwork for can decoration. These software programs allow designers to create and manipulate designs, adjust colors and ensure proper registration. They also facilitate the generation of print-ready files that can be used directly by decorating machines. - Ink and coating systems:

Ink and coating systems are critical components of can decorating machinery. These systems include ink or coating reservoirs, pumps and delivery systems that ensure a constant and controlled supply of ink or coating to the printing or coating units. Advanced systems offer color management capabilities and precise control over ink viscosity and coverage. - Inspection and quality control equipment:

To maintain high quality standards, can decorating machinery often incorporates inspection and quality control equipment. These systems use advanced sensors and cameras to detect defects such as incorrect prints, color variations or surface imperfections. Real-time monitoring and automated rejection mechanisms help ensure that only defect-free cans advance through the production line.

Conclusion:

Can decoration techniques and machinery play a crucial role in creating visually appealing and branded beverage cans. By using direct printing, labeling, shrink sleeving, embossing/sinking and coating/varnishing techniques, manufacturers can create unique designs that capture the consumer’s attention. The use of specialized can decorating machinery, together with prepress software and quality control equipment, ensures efficient and high quality production. As the industry continues to evolve, technological advances will further enhance the capabilities and possibilities of can decoration, allowing for even more creative and impactful designs.