Tightness is one of the main characteristics of a good container. The tinplate container is absolutely watertight, which makes it unalterable to external agents. This quality is essential to ensure not only the integrity of the content, whether it is food, oils, paints or other materials, but also to prevent deterioration if the product is altered by air.

The inviolability of metal packaging is a solid guarantee for consumers. If you buy a can of oil or tuna, a can of paint or a jar of asparagus, you can be sure that the contents have not been tampered with or manipulated by third parties. The contents are the same and in the same condition as when it was packaged by the manufacturer. Cans cannot be opened without being destroyed for retail purposes.

In the case of canned food, the fact that the packaging is hermetically sealed is absolutely decisive. Because the preservation process requires that product and packaging are subjected to high temperatures without the slightest loss or even the smallest crack, which would spoil the whole process. The can is the container that is best suited for this sterilization purpose.

Canned food can last for many years not only being totally useful for human consumption, but also keeping the original taste and all the nutrients it had when it was packed. But that would be of little use if the fragility of the packaging constituted a permanent risk of destruction. This is why tinplate packaging guarantees the long life of the product not only because it is an optimal container, but also because of its mechanical resistance.

A good packaging should not only contain the product, but also protect it during all the vicissitudes it undergoes from its manufacture to consumption. The can more than meets these characteristics of strength and indestructibility required for transport, store display and storage. This means not only savings by minimizing losses in the whole process, but also security for the consumer for whom the risk of accidental destruction disappears.

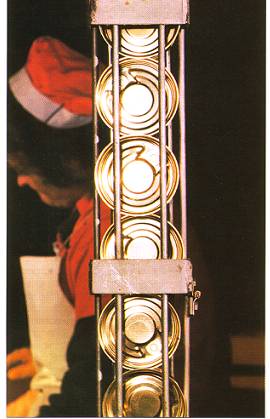

You can throw a canned food or paint can on the floor or hit it violently. At best, it will be dented, but not destroyed. This is possible thanks to the mechanical strength of tinplate, the metal from which the vast majority of cans are made. But just because tinplate is metal doesn’t mean it’s heavy. On the contrary, it is extremely light and technology is making it lighter and lighter all the time. Tinplate packaging protects products weighing more than 10 times its own weight.

Once emptied of its contents, a can, whether it is a tin of preserves, semi-preserves, vegetable oil or chemical products, weighs hardly anything: just a few grams. And yet it’s metal, tough metal if ever there was one. The explanation is simple: the high technology of tinplate and the manufacture of metal containers means that without losing an iota of such positive characteristics, the weight of the container is becoming less and less in relation to the content. Consumers are buying more and more product and less and less packaging.

In recent decades, the thickness of the tinplate used to make cans for drinks, canned food, aerosols, cosmetics or paint has been decreasing. The explanation is very simple: the thickness of the tinplate has been reduced by an average of no less than 25%, yet it retains all its strength and watertightness properties. A beverage can a century ago weighed three times as much as it does today.

Is a tinplate container safe for health? Absolutely. The absence of toxicity of all its components and its resistance to corrosion mean that, because of this, there can be no health problems. This is evidenced by its long history of more than two hundred years. Substantial technological advances in the manufacturing industry have meant that today’s packaging is completely different from the packaging used a few decades ago.

Sometimes the news of a canned food poisoning is reported in the press. This risk, which is undoubtedly serious for health, is simply the result of a bad sterilization process necessary to preserve food. If a certain temperature is not reached, bacteria that can be toxic are not destroyed. And that has nothing to do with the packaging in which the food is kept. Be careful, therefore, with home canning, which is where the risk really exists.

Have you noticed that one of the materials that make our existence more pleasant is precisely tinplate? If you look closely, you will see that you can hardly do without it. A wide range of bottles and jars can be used thanks to the tinplate caps, whether they are screw caps or crown caps, the popular caps. Aerosols for personal hygiene or domestic cleaning, car products, varnishes, paints… Tinplate is all around us thanks to its enormous versatility and flexibility. Not forgetting so many decorative elements, such as trays, bonbonnieres and boxes of all shapes and sizes.

Edible products packaged in cans are not visible. This is self-evident. But is it good or bad? Consumers certainly appreciate physically seeing what’s inside the package before they buy it, but it turns out that opacity is precisely one of the main characteristics of a good package. In fact, light acts negatively on foodstuffs, destroying their vitamin content. In the darkness of the can, the preserves retain all their nutritional properties.

When consumers buy a packaged product, it is clear that they want to buy the contents, not the packaging. Therefore, the cheaper the packaging, the less expensive the container and the contents will be, and the savings will ultimately be passed on to the buyer. Despite its many advantages, the can is a very economical container, thanks to its speed of manufacture (modern production lines reach speeds of well over a thousand containers per minute) and the low energy consumed in the process.

The comparison of the energy consumed in the manufacture of each container is hugely favourable to tinplate over the other materials currently used. This means, of course, savings for the consumer, as well as a very favourable impact on the economy, given the enormous impact of constantly rising energy costs on the economy. In the last 30 years, the steel industry has reduced the energy consumption for making tinplate by more than a third.