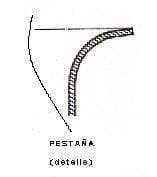

Cracked flanges in the welding of metal containers can be caused by several factors. Some of the most common causes include:

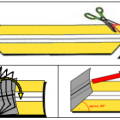

- Incorrect welding parameters: If the welding current, machine speed or welding roll pressure are not set correctly, it can cause cracked tabs.

- Wear of machine components: Excessive wear of the Z-guide tip, gauge crown or body “rest” area on the Z-guide can affect weld quality and cause cracked flanges.

- Excessive heat: Excessive heat on the weld seam of the container may cause the flange to break in the weld area.

- Material problems: If the can or flange material is defective or not compatible with the welding process, it can cause cracked flanges.

To solve this problem, it is important to check and adjust the welding parameters, keep the machine components in good condition and make sure that suitable materials are used for the welding process.

0 Comments