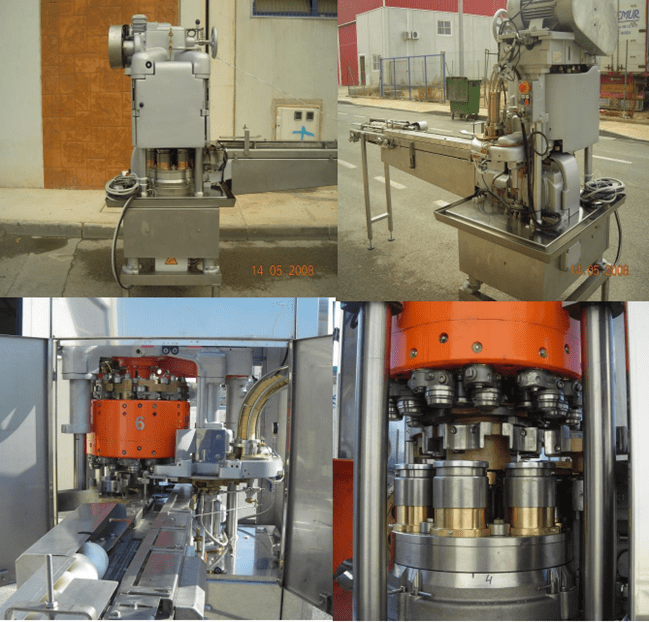

the Angelus 60L, which is a popular model in the can packing industry. 😊

The Angelus 60L is an automatic seaming machine used to seal cans of different sizes and formats. This seamer is known for its durability, efficiency and ease of use. Here are some features and details about the Angelus 60L:

- Heads: The Angelus 60L has 6 seaming heads, allowing high production speed and efficient can seaming. The heads are designed to adapt to different can sizes and formats.

- Rollers: The Angelus 60L uses sealing rollers to seal the cans. Each closing head has two rollers, one for the first closing operation and one for the second closing operation. These rollers are designed to adapt to different can sizes and formats, and can be replaced or adjusted according to production needs.

- Production speed: The production speed of the Angelus 60L can vary depending on the size and format of the cans, as well as the machine configuration. In general, this seamer can reach speeds of up to 500 cans per minute.

- Ease of use and maintenance: The Angelus 60L is designed to be easy to use and maintain. The machine has an intuitive and accessible control panel, and its components are easily replaceable or adjustable according to production needs.

- Versatility: The Angelus 60L is compatible with a wide variety of can sizes and formats, making it ideal for companies dealing with different types of canned products.

If you are interested in more information about the Angelus 60L seamer or need help setting it up and using it, I would recommend that you contact the manufacturer or an authorized distributor. They will be able to provide you with more detailed and specific information about the machine, as well as advice on its operation and maintenance.