Annually, about 6 million tons of food is wasted in Japanese households and businesses. Precisely to counteract this significant expense, the Japanese food industry is making great efforts to reverse this problem. However, to extend the shelf life of these foods, we must take into account other significant aspects such as an increasingly aging population so we must take into account other added aspects such as an easy to open design as well as guaranteed food safety.

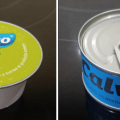

One of the designs that meets this demand is that of the Japanese Showa Aluminiun with its Almic-Can TM. It is an innovative pressure moulded food container with a laminated aluminium foil and a resin foil. The aluminum provides high barrier properties, while the resin foil, which consists of a sealing layer and a peel layer, provides the easy peel property combined with the high decorticability and molding flexibility of the resin container.

The use of aluminium foil on both the lid and the container prevents the entry of oxygen, humidity and light from the outside, thus preventing oxidation, drying and discolouration of the food. Once the can is full of food, it can be sterilized by heat and pressure. Because foods in autoclave pouches can be heat sterilized while still sealed, loss of water-soluble nutrients or those that can easily oxidize is minimized. The sterilization process allows food to be distributed and stored at room temperature.

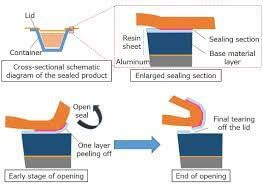

The resin sheet consists of a peel coat and a seal coat. The peel-off layer can be easily peeled off from the base material layer, the sealing layer being fully welded, making the container resistant to internal pressure, easy to open and leak-proof. The can is designed to have a standard opening strength of 15 N, which is considered easy for people to open, combined with a high seal strength of 50 kPa or higher. This allows children and the elderly to open the can comfortably and easily.