Introduction

The Bodymaker is an essential machine in the aluminum beverage can production process. It plays a crucial role in shaping the aluminum cup into a recognizable can, complete with a thin side wall and a formed bottom. This article delves into the intricacies of the Bodymaker, its operation, and its significance in the aluminum can manufacturing process.

Bodymaker Overview

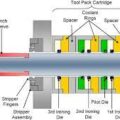

The Bodymaker is a specialized machine designed to transform aluminum cups into beverage cans. It achieves this through a series of tools, including redraw and ironing rings, which work together to reduce the diameter and side wall thickness of the cup while extending its height.

The Process

The aluminum cup, which serves as the starting material for the can, is drawn through a set of tools in the Bodymaker. These tools include redraw and ironing rings numbered 1, 2, and 3. Each ironing ring has a progressively smaller inside diameter, causing the can wall thickness to decrease as the cup passes through them.

During the reduction of the side wall thickness, the continuity of the material may sometimes be broken, generating a defect called the “short can.” Minimizing the occurrence of this defect is an important aspect of the aluminum can production process.

Lubrication and Cooling

To prevent the aluminum from tearing during the ironing process, lubricant is added to the can before it passes through the rings. The lubricant also helps cool down the aluminum, as heat is generated due to the friction caused when the can is forced through the rings.

Forming the Bottom

After the can passes through the last ironing ring, its bottom is pressed against a tool that forms the base of the can. This is achieved in one continuous punch stroke, ensuring a seamless transition from the cup to the finished can.

Ear Formation

Due to the anisotropic nature of sheet aluminum, “ears” are formed at the top of the can when it is shaped in the Bodymaker. These ears are later trimmed off in the production process to ensure a smooth, uniform appearance for the final product.

Conclusion

The Bodymaker is a vital component in the aluminum can production process, responsible for transforming aluminum cups into the familiar beverage cans we use daily. By utilizing a series of specialized tools and lubrication, the Bodymaker ensures the efficient and precise formation of cans with thin side walls and a formed bottom. Understanding the intricacies of this machine and its operation is essential for optimizing the production of aluminum cans and minimizing defects.