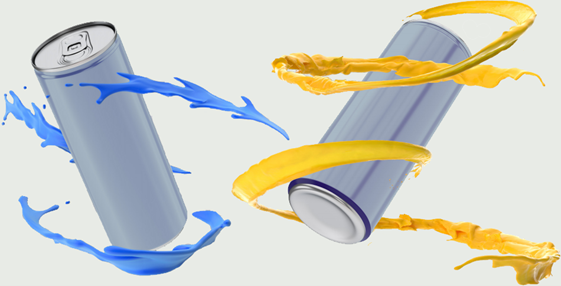

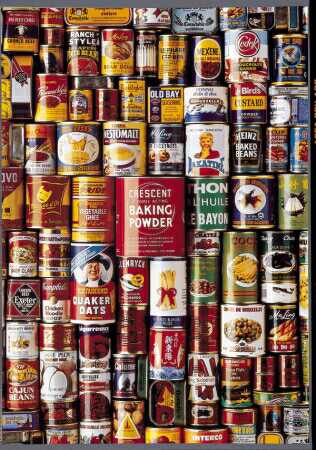

The CMYK (Cyan, Magenta, Yellow and Black) process is a color model used in the printing of aluminum cans and other materials. This model is based on the mixture of these four basic colors to create a wide range of shades. Here’s how the CMYK process works in can printing:

- Design preparation: Before printing begins, a digital design is created in graphic design software. This design is divided into four separate layers, each corresponding to one of the CMYK colors. Each layer contains information on the amount of ink to be applied to each area of the can for that specific color.

- Creation of printing plates: For each color, a printing plate containing the corresponding layer information is created. These plates are cylindrical and are used in the rotary printing machine.

- Can printing: The aluminum can is placed in the rotary printing machine, which prints each color separately. The machine applies the ink of each color on the can through the printing plates, overlapping the colors to create the final design. Depending on the machine model, six to eight colors can be printed, including CMYK colors and additional colors if required.

- Drying and curing: After printing, the cans go through a drying and curing process. This involves applying a coat of varnish over the ink and drying it in an oven at approximately 180 degrees Celsius for 60 seconds. This process ensures that the printed layer has stability and rub resistance.

- Interior protection: To protect the inside of the can and the product it will contain, a varnish is applied to the inside of the can using atomizing nozzles. The cans then go through a curing oven to dry the varnish.

In summary, the CMYK process in aluminum can printing involves creating a digital design divided into layers of color, using printing plates to apply each color, and layering these colors to create the final design. This process guarantees high printing quality and a wide range of colors on aluminum cans.