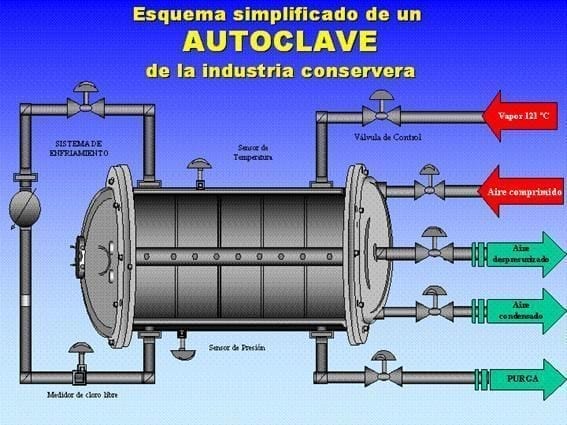

Club cans may experience rusting at the corners after sterilization due to several factors. One of these is improper post-cooling handling, where residual moisture can lead to corrosion, especially if cans are packed while still wet, creating a humid atmosphere that favors oxidation over time. In addition, external deburring of the double seam by adhesion of the varnish on the roller profiles during sealing can expose the metal to corrosion. Also, the bulk arrangement of cans in autoclaves can cause some lids or bottoms to mark each other and lose varnish during the thermal process, which increases the risk of oxidation.

To prevent oxidation, it is important to control the cooling rate and the final cooling temperature, to ensure that the cans dry quickly and spontaneously after cooling, and to perform drying operations with hot air currents at the exit of the cooling. In addition, the container can be washed and dried with treated deionized water to remove salts and other contaminants that may accelerate corrosion.

Critical parameters

- Container closure control: Critical parameters must always be respected to ensure proper closure and avoid problems such as corrosion or contamination of the contents.

- Critical limits in food processing: These are established to ensure product safety and quality. These can be quantitative values, such as pH and temperature, or more subjective qualities, such as appearance, which are assessed by visual inspection. Critical limits must be based on reliable data and provide a controlled operating margin.

- Facility Hygiene: Compliance with Good Manufacturing Practices is a critical threshold for hygienic conditions.

- Preparatory and conditioning operations: They must also comply with Good Manufacturing Practices.

- Cooking: The temperature-time binomial must reach the specifications established by each manufacturer, such as a minimum of 71°C in the backbone for certain processes.

- Aggressiveness of food: Depending on the acidity or alkalinity of the food, different types of interior varnish coatings are required to protect the container from chemical attack.

- Package strength: Factors such as package thickness, material temperature and product design are critical to withstand the heat treatment process.

These critical parameters must be constantly monitored and controlled to ensure that the process remains within acceptable limits and to prevent any failure that could compromise the quality and safety of the product.