Nowadays it is very important to have a good operational decorator and all can makers are trying to do everything they can to get more cans and more output.

But to get an improvement in production, such as printing faster and reducing spoilage is not easy. Therefore, in my opinion, it is very important to have a good and stable printing machine. How can this be achieved? With the Infeed. This small area can be the cause of good or bad production. It doesn’t matter if it is a Concord or Rutherford.

Infeed in a decorticator is very sensitive and the influence of different areas can cause a big problem.

In the early days of can decorating, speed was not that important, so feed was coupled to speed.

The cans pushed in the infeed only using gravity. With this idea, the decorticator was able to run at least at a speed between 600-800 cpm.

The decorator speed at this time was just shy of having enough cans going through the Deco and printing was only 4-color, with a maximum speed of only 800-1000cpm at most.

Subsequently, the demand for cans was increasing and the manufacturer was under pressure to produce enough cans for the industry.

The new generation was then called CD2, before the name was just CMP (continuous motion printer), the CD2 (Decorator generation 2) was now capable of running at over 1000cpm by using a vacuum star wheel infeed at a 30 degree angle.

Cans were now pushed through an Airtrack feeder and placed on the mandrel with a vacuum starwheel.

Cans were loaded at a 30-degree angle just to make sure the can slid smoothly and fast enough at a higher speed of 1000cpm.

With this new style of feeding, can makers were able to produce more cans and faster, but soon this 1500cpm speed was not enough to meet the demand for cans.

So the next generation of feeders was needed, and a completely new idea was designed.

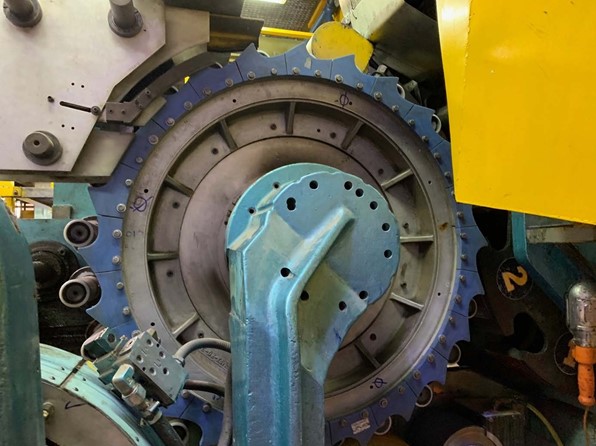

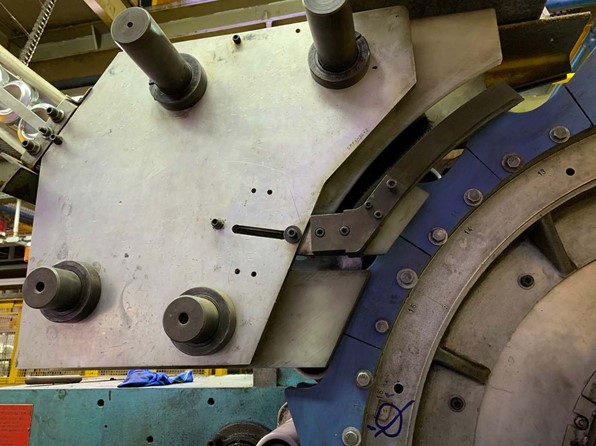

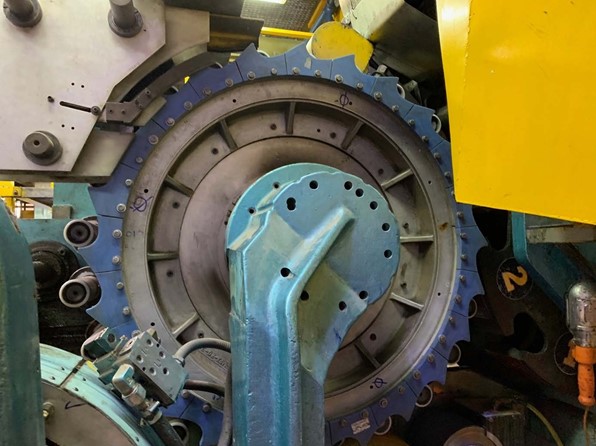

Previously it was sufficient to use a 30 degree angle to have enough cans loaded at a higher speed, but now the new design was using a vertical infeed like 90 degrees to push the cans with high speed through the feeder.

To achieve this, it was decided to have the loading point lower than 30 degrees to have more time to load the cans.

This new design means that the can maker now has more time for the loading procedure and the cans now use a vertical infeed to load them.

This type of infeed can now reach a printing speed of 2200cpm, with better control of the can loading through a special type of starwheel design.

The new vertical infeed has the ability to make a size change in a short time as most of the components are now on the outer side.

At this time this is the most common thing that all can makers are using, but however there are more elements that can cause a misload.

For example, if the mobility of the cans is good, your feeder is loading the cans and all is well, but as soon as the mobility of the cans gets a little out of range, then you will see the reaction in the decorticator, which will start to pull the cans out and the spoilage will increase due to the high ejection.

On the other hand there is the inlet maintenance, if this is not done very well and accurately, it can also cause some headache. It’s just a small misadjustment and the Deco is already ejecting the cans again.

The feeder is also very sensitive to temperature. For example, the feeder was running fine on the first shift in the morning and in the afternoon on the second shift, the feeder is also ejecting cans like hell, this is because the ambient temperature has changed and this is affecting the load.

Over the years at the facility, I have seen feeders covered by air conditioning to make sure they have the same temperature at all times.

In the past, the feeder was designed to print cans at 800cpm, but due to the high demand for cans, the can maker is looking for more speed and more cans, and this is only possible if the feeder is set perfectly right.

Currently, in my opinion, this is the key point of the whole production area, and this must be modified to adapt to the high demand for cans.

0 Comments