Introduction

Tear-offs are one of the most common defects encountered in can-making machinery, specifically in bodymakers. This technical article aims to provide a comprehensive understanding of tear-offs, their causes, and effective troubleshooting methods to minimize their occurrence and improve the overall efficiency of the bodymaker.

What are Tear-Offs?

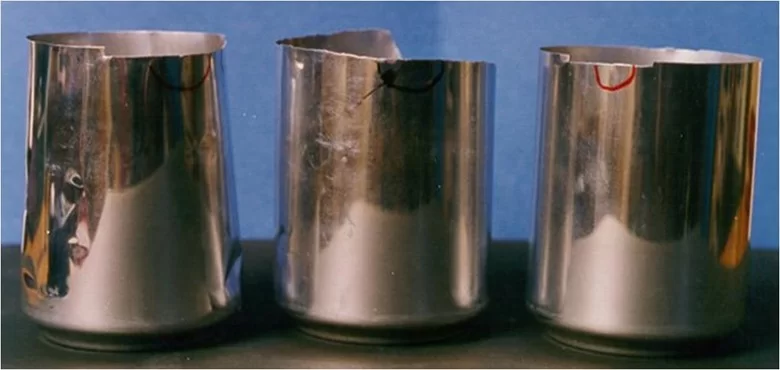

Tear-offs are a type of defect that occurs when a portion of the can body material tears away during the forming process. This results in an incomplete or damaged can that cannot be used for its intended purpose. Tear-offs can be caused by various factors, including issues with the machinery, metal quality, or die lubrication system.

Causes of Tear-Offs

- Metal quality: Inconsistent or poor-quality metal can contribute to tear-offs. If the metal is too thin, too hard, or has surface defects, it may not form properly and result in a tear-off.

- Die lubrication: Insufficient or excessive lubrication can lead to tear-offs. Proper lubrication is crucial to ensure smooth metal flow during the forming process.

- Cupping press issues: Problems with the cupping press, such as misaligned or worn dies, can cause tear-offs.

- Bodymaker settings: Incorrect bodymaker settings, such as improper ram pressure or die clearances, can result in tear-offs.

- Mechanical failures: Wear and tear on the bodymaker components, such as bearings, gears, and springs, can lead to mechanical failures that cause tear-offs.

Troubleshooting Tear-Offs

To effectively address tear-offs in bodymakers, a systematic troubleshooting procedure should be followed:

- Collect baseline data: Establish the acceptable tear-off level and gather data to show evidence of an increase in the tear-off rate. Identify if the increased tear-off level is only evident when running a particular supplier’s coil.

- Identify affected machinery: Determine which bodymakers or cup stations are experiencing tear-offs.

- Examine defective cans: Analyze the tear-offs to determine their type and location. Note the position of the defect relative to the height of the can, the identification mark on the bottom, and the rolling direction of the metal.

- Investigate potential causes: Based on the analysis of the defective cans, investigate the possible causes of tear-offs, such as metal quality, die lubrication, cupping press issues, bodymaker settings, or mechanical failures.

- Implement corrective actions: Address the identified causes by adjusting bodymaker settings, replacing worn components, improving metal quality, or optimizing die lubrication.

- Monitor progress: Continuously monitor the tear-off rate to ensure that the implemented corrective actions are effective in reducing the occurrence of tear-offs.

Conclusion

Tear-offs are a common defect in bodymakers that can significantly impact the efficiency and quality of can production. By understanding the potential causes of tear-offs and following a systematic troubleshooting procedure, it is possible to minimize their occurrence and improve the overall performance of the bodymaker. Regular maintenance, proper lubrication, and attention to metal quality are crucial in preventing tear-offs and ensuring the production of high-quality cans.