1. Introduction

In the process of decorating two-piece aluminum cans, the ink system is central to graphic performance. Although the blanket cylinder transfers the image to the can body and the plate cylinder contains the design, it is the inkwell—a set of perfectly adjusted rollers—that ensures printing is carried out:

- Uniform in color

- With good sharpness of detail

- At speeds exceeding 2,000 cans per minute

A minimal alteration in the ink delivery—whether excess or lack, variation in temperature or pressure—immediately translates into defects such as:

- Tone variation

- Dot deformation (dot gain)

- Visible bands

- Dirty or undefined contours

Therefore, the inkwell is simultaneously a precision mechanical organ and a graphic control mechanism.

The training makes a key philosophy clear:

Minimum pressure, maximum definition.

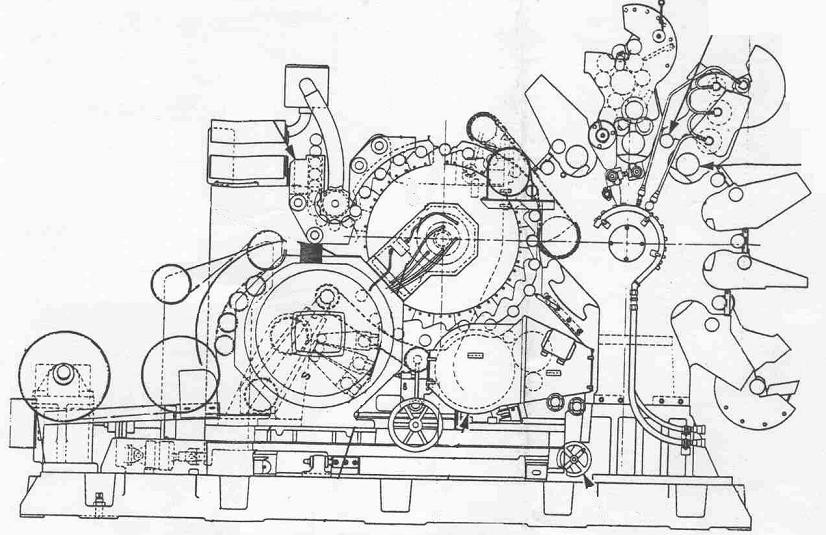

2. How the ink moves in the system

The ink’s journey begins at the source, reaches the fountain roller, and enters a chain of rigorously synchronized rollers that lead it to the raised areas of the photopolymer plate. The blanket will pick up that image to print it on the can.

Technical sequence of the ink path:

Source → Fountain roller → Transfer roller → Steel roller → Distributor rollers → Oscillating rollers → Main rollers → Plate cylinder → Blanket → Can

Each roller has a specific function within the quality of the process.

If one fails, the error is multiplied downstream.

3. The Ink Source — First element of quality

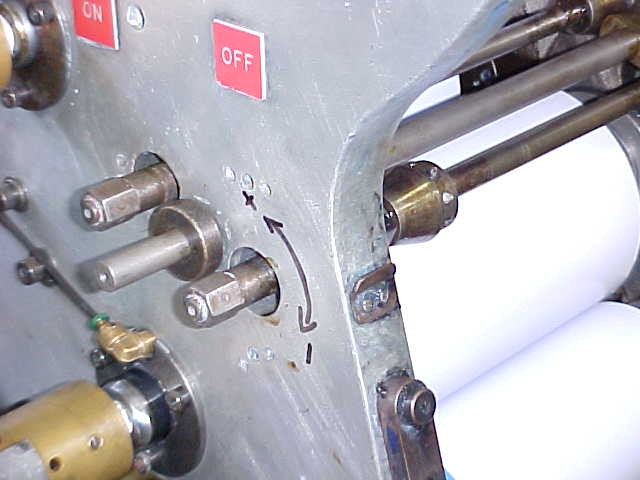

The source contains the ink and dispenses it using an adjustable blade. It has nine adjustment points along its length to precisely regulate the amount of ink transferred to the roller.

- Turning the screw counterclockwise → increases the ink

- Turning clockwise → reduces the ink

You can also adjust the tilt to prevent the ink from oxidizing or drying out when working with small volumes.

If the source control fails, the entire system will amplify it:

Too much ink → excess pressure → heat → dot gain

Little ink → washed colors → low density

Nothing is corrected later:

If the ink comes out of the source wrong, it reaches the can wrong.

4. The rollers: the engineering behind the printing

Transfer roller

In addition to transporting the ink, it receives eccentric movement from a cam, guaranteeing:

- Stable rotation

- Controlled ink transfer

- Wear compensation even with short stops

If this oscillation deteriorates → vertical bands appear.

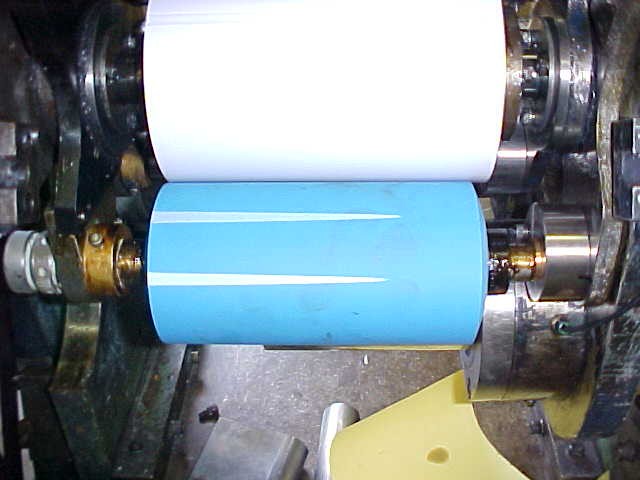

Distributor and oscillating rollers

The ink is not just a film: it must be uniform across the roller.

The oscillating rollers move laterally to avoid:

- Dry zones

- Tone variation between sides

- Bands in solids

- Lack of sharpness

Main rollers

There are two with different diameters:

| Roller | Main function |

| Left main roller (F1) | Work with details and highlights |

| Right main roller (F2) | Work in solids and large areas |

Both touch:

- Oscillating rollers

- Plate cylinder

Its adjustment determines the final quality of the image.

5. Contact pressure — Where quality is decided

The pressure setting is critical.

The objective: contact without deformation.

| Excess pressure | Lack of pressure |

| Dot deformation | Lack of ink |

| Dirty edges | Weak tone in details |

| Heating | Washing of highlights |

| Excessive wear | Tone variation |

Verification is done by observing the ink on the rollers during start-up.

The contact marks always reveal the real problem.

The roller never lies.

6. Cooling — Invisible stability

The performance of the ink and the condition of the rollers depend entirely on the temperature. Therefore, the steel rollers and the gearbox are supplied with chilled water at a temperature between 22 °C and 25 °C.

If the temperature exceeds this range:

- The ink changes viscosity → unstable color

- The polyurethane rollers may swell

- Friction and noise increase

- The stability of the process degrades

A new configuration guarantees reaching all rollers with the same temperature.

This avoids “hot spots” that only affect one printing area.

7. Safe and efficient cleaning

During color changes, cleaning is performed with the ink collection system:

- The collector is installed

- Alcohol is applied to the source

- The residual ink flows into the collector

- It is removed and safely discarded

This avoids:

- Hand contact with moving mechanisms

- Contamination by fibers or residues

- Excess of rejected cans during the transition

Less dirt = more safety = more availability.

8. Troubleshooting by reading the print

Printing is a real-time diagnosis.

Each visible defect is the direct consequence of a mechanical or pressure mismatch.

| Visible defect | Root cause | Recommended action |

| Washed tones | Lack of ink / low pressure | Increase supply in source / check contacts |

| Dirty edges or halos | Excess ink and pressure | Reduce pressures progressively |

| One side darker | Lack of parallelism | Readjust critical rollers |

| Loss of fine detail | Dot gain | Reduce pressure on the plate |

| Color variation over time | Cooling problems | Check water flow / temperature |

There is no defect that does not have a mechanical explanation.

9. Precision at high speed

This process is a combination of relief printing and dry offset, which allows printing on a metal surface without a fountain solution.

Advantage:

- No water-ink interference

Challenge:

- Reproducing very fine details is more complex due to dot gain

And everything happens at extreme speeds:

At more than 2,000 packages per minute, any small error becomes a major defect.

If the pressure deviates → the tone changes

If the temperature changes → sharpness is lost

If a roller stops oscillating → the band appears in seconds

In cans, speed does not forgive.

10. Conclusion

The ink system is the quality engine in a can decorator.

If the source dispenses well → the color is stable

If the rollers are aligned → the tones are reproduced correctly

If the temperature is controlled → the definition is maintained

If the cleaning is efficient → the restart leaves no traces

Everything works for a single objective:

To deposit only the necessary ink, only in the raised areas of the plate,

just when the can contacts the blanket.

The inkwell does not forgive errors.

But it always gives clear signs of what is wrong.

Whoever learns to interpret them becomes a true printer.