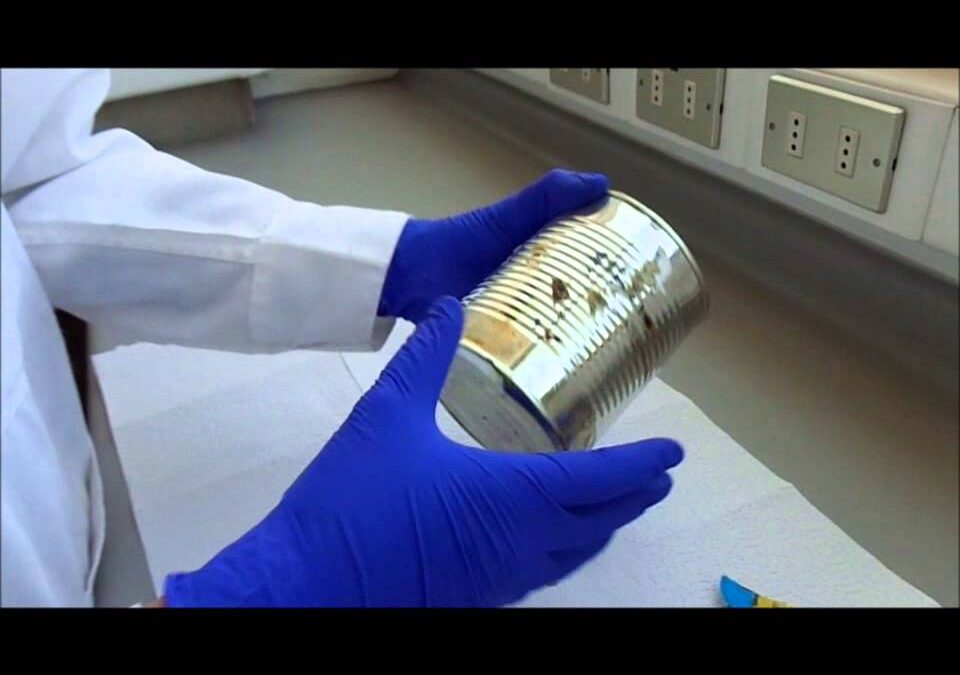

Blushing is a phenomenon that occurs during the manufacturing process of tinplate food cans, specifically during the thermal process. This problem manifests itself as the adsorption or absorption of components, generally water, in the varnish applied to the tinplate. This white paper focuses on identifying the causes of blushing, its effects on package quality and possible solutions to mitigate this problem.

Definition and Causes of Blushing

Blushing is a defect that appears as a whitish discoloration or milky appearance on the surface of the varnish applied to tinplate cans. This effect is mainly due to the absorption of moisture by the coating during the thermal curing process. Common causes of blushing include:

- Poor curing of the varnish, which may be due to inadequate temperatures or incorrect curing times.

- The presence of excessive moisture in the curing environment.

- Varnish formulation that is not suitable for the processing conditions or for the ambient moisture content.

Effects of Blushing on Package Quality

Blushing can have several negative effects on package quality, including:

- Decreased chemical resistance of the coating, which can lead to increased susceptibility to corrosion.

- Alteration of the aesthetic properties of the packaging, which may negatively affect the consumer’s perception.

- Possible compromise of package integrity, which may affect food preservation.

Solutions and Prevention

To prevent blushing and ensure proper cure of the coating, the following measures can be taken:

- Optimize thermal curing parameters, including temperature and time, to ensure complete curing of the coating.

- Control the ambient humidity in the curing areas to minimize water absorption by the coating.

- Select coatings suitable for the specific processing conditions and for the characteristics of the product to be packaged.

- Perform regular quality tests to detect the presence of blushing and take corrective action in a timely manner.

Conclusion

Blushing is a problem that can affect the quality and integrity of tinplate food cans. It is essential that manufacturers understand the causes and effects of this phenomenon in order to implement appropriate preventive and corrective measures. By doing so, they can ensure the quality of the packaging and the protection of the product contained.

This white paper has provided an overview of blushing, highlighting the importance of proper varnish curing and environmental humidity control in the manufacture of tinplate food cans. Prevention and correction of blushing are critical steps in maintaining the quality and safety of the packaged product.