Stolle Machinery has introduced a significant upgrade for its Rutherford Decorator: a high-performance inker that promises to improve print quality, facilitate operation, and extend the lifespan of components.

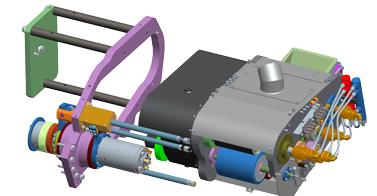

The new inker incorporates an innovative design of the plate cylinder shaft and drive system, as well as the ink station. Separating the plate cylinder shaft from the ink station allows the latter to be removed without affecting plate synchronization, while lateral and circumferential register adjustments can be made with the machine running. In addition, the pressure between the plate and blanket can be regulated during operation.

The ink station has been redesigned with a rigid frame that increases the durability of bearings and shafts. The ink train has been simplified, reducing size and optimizing energy consumption, while the tub capacity has been increased by 40% thanks to a removable tray and a segmented blade system for more precise adjustments. Leak-free side seals and quick-release fasteners facilitate maintenance and cleaning.

All ink station adjustments are now made from the operator’s side and can be performed during printing. In addition, the new safety cover allows access to the tub and adjustments without exposing rotating components, improving safety and reducing ink dispersion.

The High Performance Inker can be retrofitted to any 8-color Rutherford Decorator