Despite being the fastest growing sector in the wine packaging market, canned wine faces certain obstacles. It does not enjoy the same elegance as bottled wine and is not as popular as the underrated “boxed wine bag”. In addition, it should also be mentioned that canned wine can sometimes have an unpleasant odor similar to rotten eggs. Gavin Sacks and Julie Goddard, professors of food science in the College of Agriculture and Life Sciences, are collaborating with wineries, manufacturers and New York State to eliminate the unusual product odor through changes in formulation and packaging. It also seeks to solve its corrosion problem.

According to a recent study reported in the American Journal of Enology and Viticulture (AJEV), it was determined that the choice of ultra-thin plastic material used inside aluminum cans can have a positive impact on the aroma and durability of the beverage in its packaging.

What is the reason Coca-Cola is not facing this situation?

The collaboration between the winemakers and Sacks began a few years ago, when the latter approached the former with difficulties in the quality of their canned wines, such as corrosion, leaks and an unpleasant rotten egg smell mixed with the fruity and floral notes.

According to Sacks, the can suppliers had given the company recommendations, but despite following them they still had problems. So they turned to him for help. The first step was to identify which were the problematic compounds and the cause of corrosion and foreign odors in the wines. They wondered why this problem only occurred in wines and not in sodas, since Coca-Cola did not have this problem.

Sacks and Goddard pooled their expertise in flavor chemistry and materials science to conduct experiments related to the chemical composition of commercial wines. In addition, they evaluated the possible corrosion and foreign odors present in these products.

According to Sacks, a study with an epidemiological approach was initially carried out. Can producers have an extensive list of substances that could be problematic, so it was necessary to measure as many components as possible.

The scientists stored the first samples in cans with various internal coatings for a period of eight months. They also subjected another sample to an accelerated aging process by placing it in ovens at high temperatures for one to two weeks. In addition, they created their own wine using precise amounts of the suspected compounds that could cause problems.

Different research and tests have shown that the presence of sulfur dioxide (SO2) in its molecular form is the main factor to be taken into account in predicting possible can failures, such as corrosion or unpleasant aromas. Although winemakers use it as an antioxidant and antimicrobial, the plastic coating on the inside of the can does not completely prevent the interaction between SO2 and aluminum, which can result in the production of hydrogen sulfide (H2S) and a rotten egg-like odor. This conclusion was proven with solid evidence.

As stated by Sacks, when measuring different aspects, they did not find a clear correlation. However, it was observed that molecular sulfur dioxide (SO2) showed a certain relationship in the wines. In general, wineries manage a level of 0.5 to 1 part per million (ppm) of SO2 in their products. It was noted that in those wines with more than 0.5 ppm molecular SO2, a significant increase in hydrogen sulfide or the characteristic rotten egg odor occurred within four to eight months.

After conducting a series of tests and analyses, the team concluded that maintaining 0.4 parts per million (ppm) of sulfur dioxide (SO2) in wine and using epoxy coatings would be the best way to prevent excessive hydrogen sulfide formation during prolonged storage in cans for up to eight months.

One winery expert suggests that they should aim for a lower level of comfort to ensure product quality. Although there can be problems with oxidation, the cans offer a tight, well-made seal and are unlikely to allow air to enter, which is highly valued by brewers as it helps prevent oxidation.

There is a contradiction in the fact that molecular sulfur dioxide is the cause of bad odor in canned wine. Generally, SO2 levels are higher in white wines than in red wines. However, many companies choose not to can their red wines because consumers tend to associate cans with lower quality and less sophisticated products.

According to Sacks, when you go to a store, you are likely to find more sparkling, white and rosé wines in canned format, but unfortunately these products are the most likely to have problems.

Austin Montgomery, a Ph.D. student, and Rachel Allison, who holds a Ph.D. degree, were the lead authors of the paper that won the 2024 Best Enology Paper Award from AJEV.

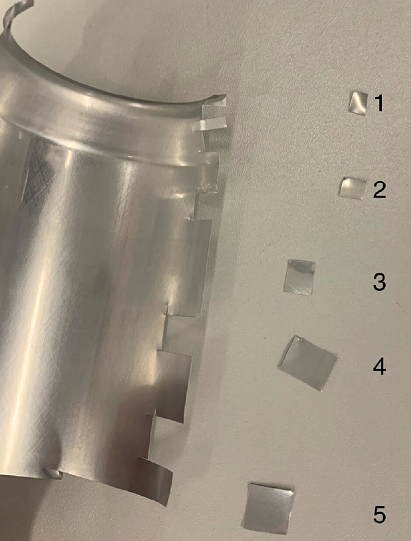

The follow-up report, prepared by PhD student Matthew Sheehan, addressed how the diversity of metal coatings influences hydrogen sulfide production.

According to Sacks, the most relevant thing about wine is not its composition, but the way it is made. However, a wide variation has been observed among manufacturers even when they claim to use the same type of plastic material in their production. In an attempt to understand these differences, they have conducted research to find the reason behind this.

According to the research team, it was found that as the thickness of the can coating increased, there was a lower incidence of corrosion. However, they also noted that the interactions between the wine and the coating could vary during the storage process.

However, finding a solution to this problem is not so simple. Sacks asserts that the use of thicker coatings has several important disadvantages. Not only are they more expensive to produce, but they are also less environmentally friendly since during the aluminum recycling process, the thicker plastic is burned and generates pollution.