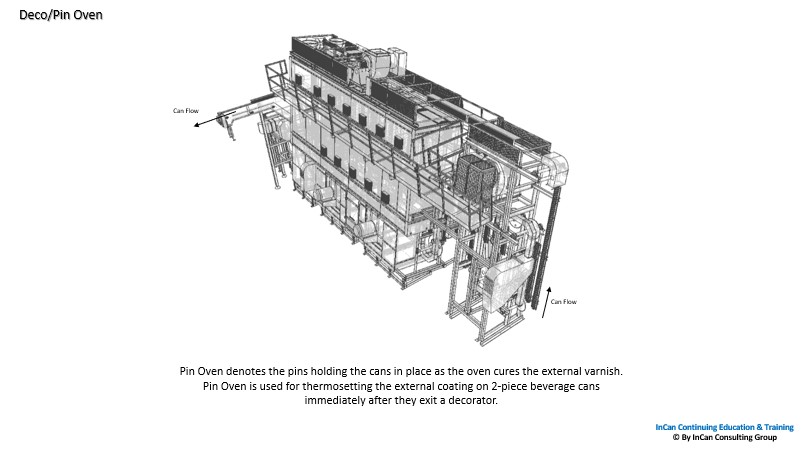

Pin Oven (Pin Oven)

Designed specifically for the curing of exterior varnish on cans, a curing process that takes place immediately after the cans come out of the printing process.

This curing oven is located after the dome label printer and coater, its speed depends on the speed of the printer as they share the same Pin Chain.

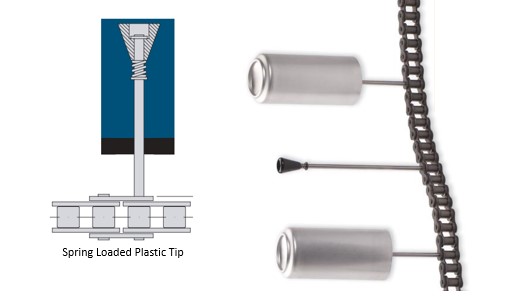

This oven is called Pin Oven because of the pins that hold the cans in position during their travel inside the oven, which in turn performs the curing of the exterior varnish.

The Pin Chain is built to withstand extreme temperatures, high tension and speed variations, but at the same time it must provide stability to the cans during their travel inside the pin oven.

The bolt furnace has a typical inclination of 13°, this is because the cans are held on the bolts via gravity, there is no vacuum or suction system to hold the cans on the bolts during their travel inside the furnace.

There are basic points to consider in the design of a bolt furnace:

– The stability of the can on the bolt during its travel inside the furnace.

– Handling of cans during their travel using the lowest centrifugal force.

– Minimize can waste by complying with the required temperature and residence time.

– Achieve the desired temperature ramp with efficient heat transfer.

– Temperature uniformity in the can, industry standard is ± 5°F across the entire can.

There is only one bolt furnace per can printer; depending on the size and format of the can, that will be the design or size of the bolt furnace.

1.

The Bolt Oven designates the pins that hold the cans in place while the oven cures the external varnish.

The Bolt Oven is used to heat seal the outer lacquer of 2-piece beverage cans immediately after they come out of a decorator.

2.

Cans must be transported safely and reliably at high speeds and temperatures.

The needle furnace chain is built to withstand extreme temperatures, tension and variable speeds.

Kindly we need a prices for cans line