In the intricate world of can decorating, where precision and efficiency are paramount, Stolle Machinery’s integration of Mastercam technology into its presses is a major leap forward. This article delves into the nuanced functionalities and fine-tuning facilitated by Mastercam integration.

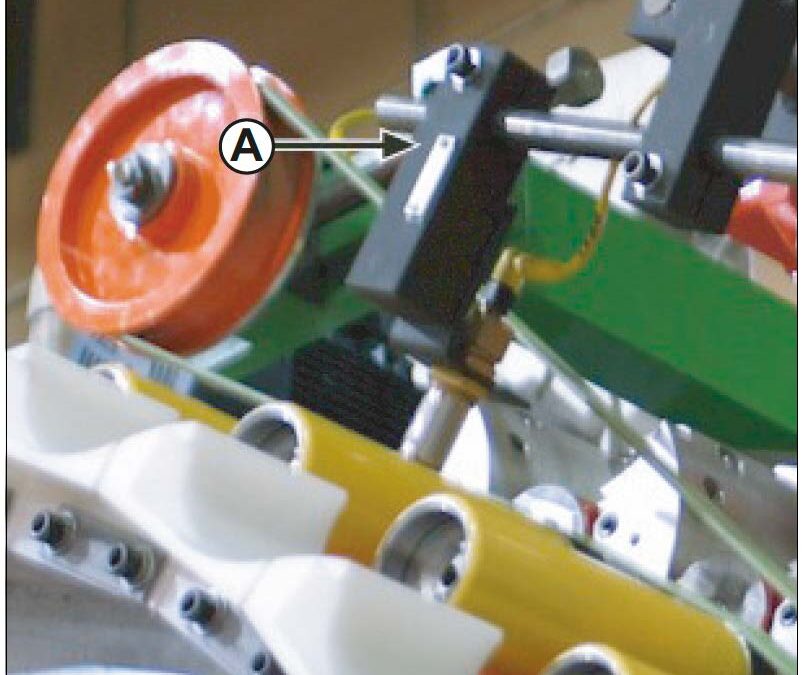

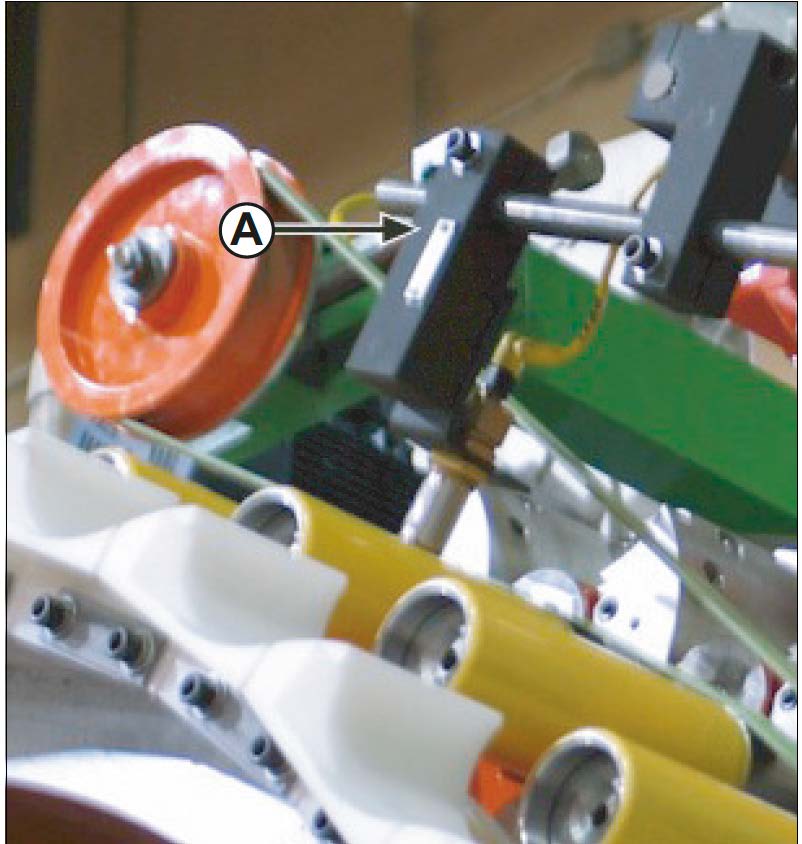

Mastercam, ultimately transforming the can decorating process into a seamless and precise operation. At the heart of the integration is the electronic can sensor, a critical component responsible for detecting the presence of each mandrel sleeve. This sensor, closely linked to the central logic unit, acts as the initial control point in the printing process. Upon detection of an empty mandrel station, a cascade of actions is triggered. Solenoid valves are activated, trigger actuators are engaged and the mandrel passes smoothly through the print area without leaving an unwanted trace, all orchestrated by Mastercam’s precision control.

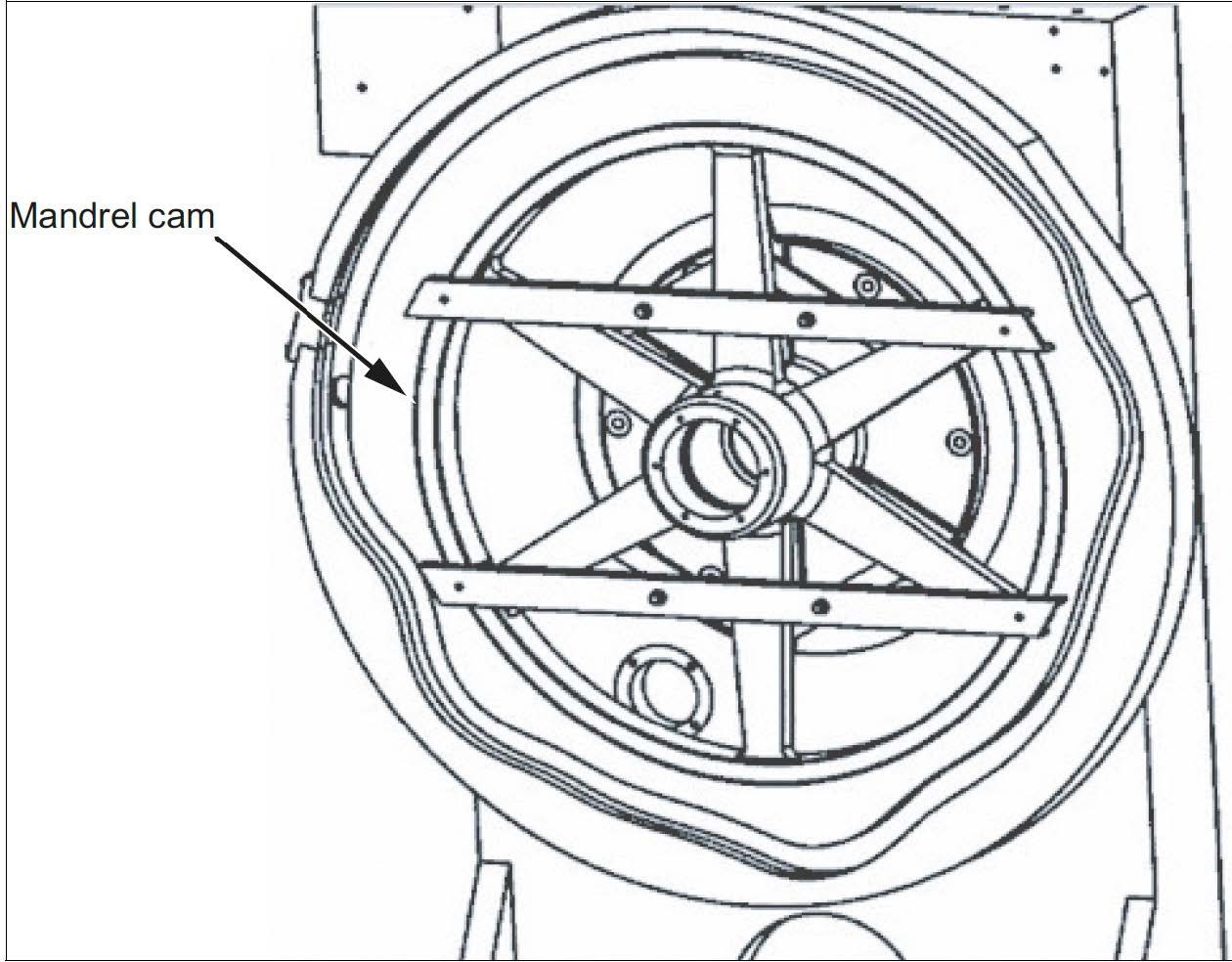

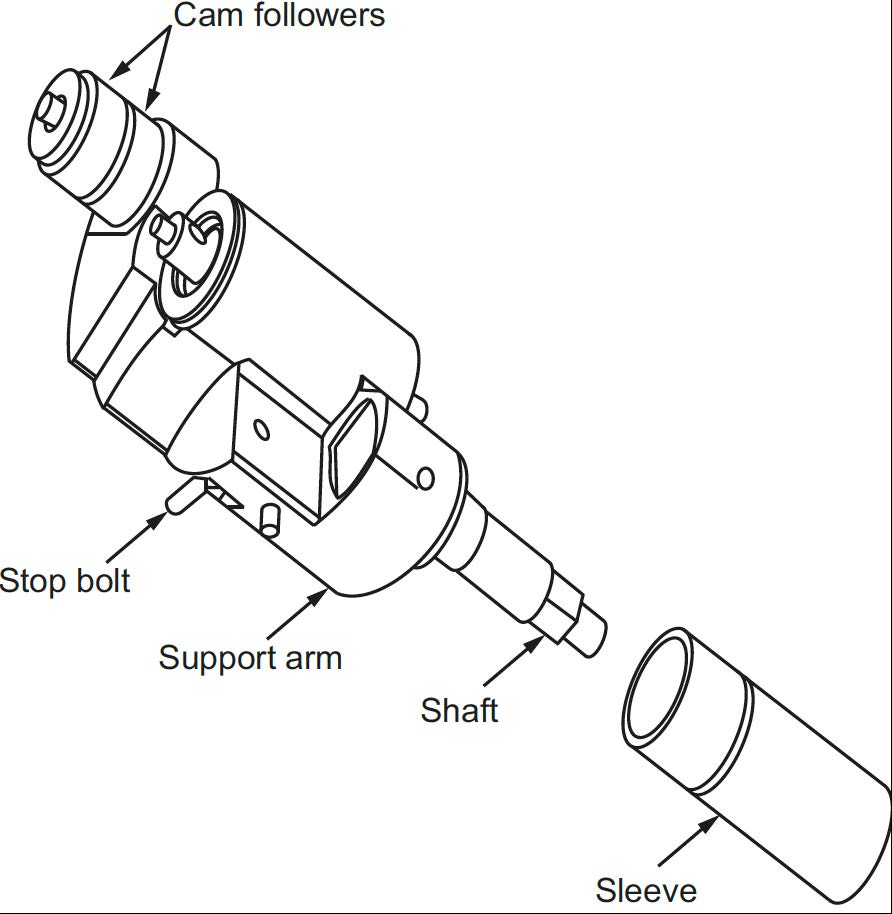

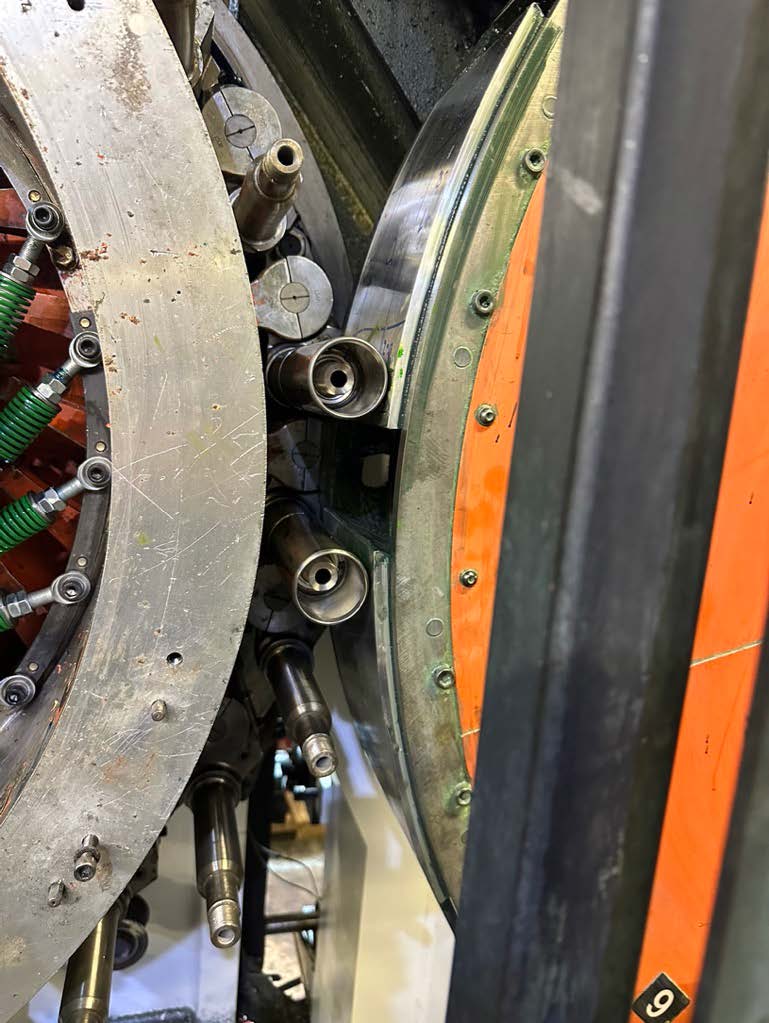

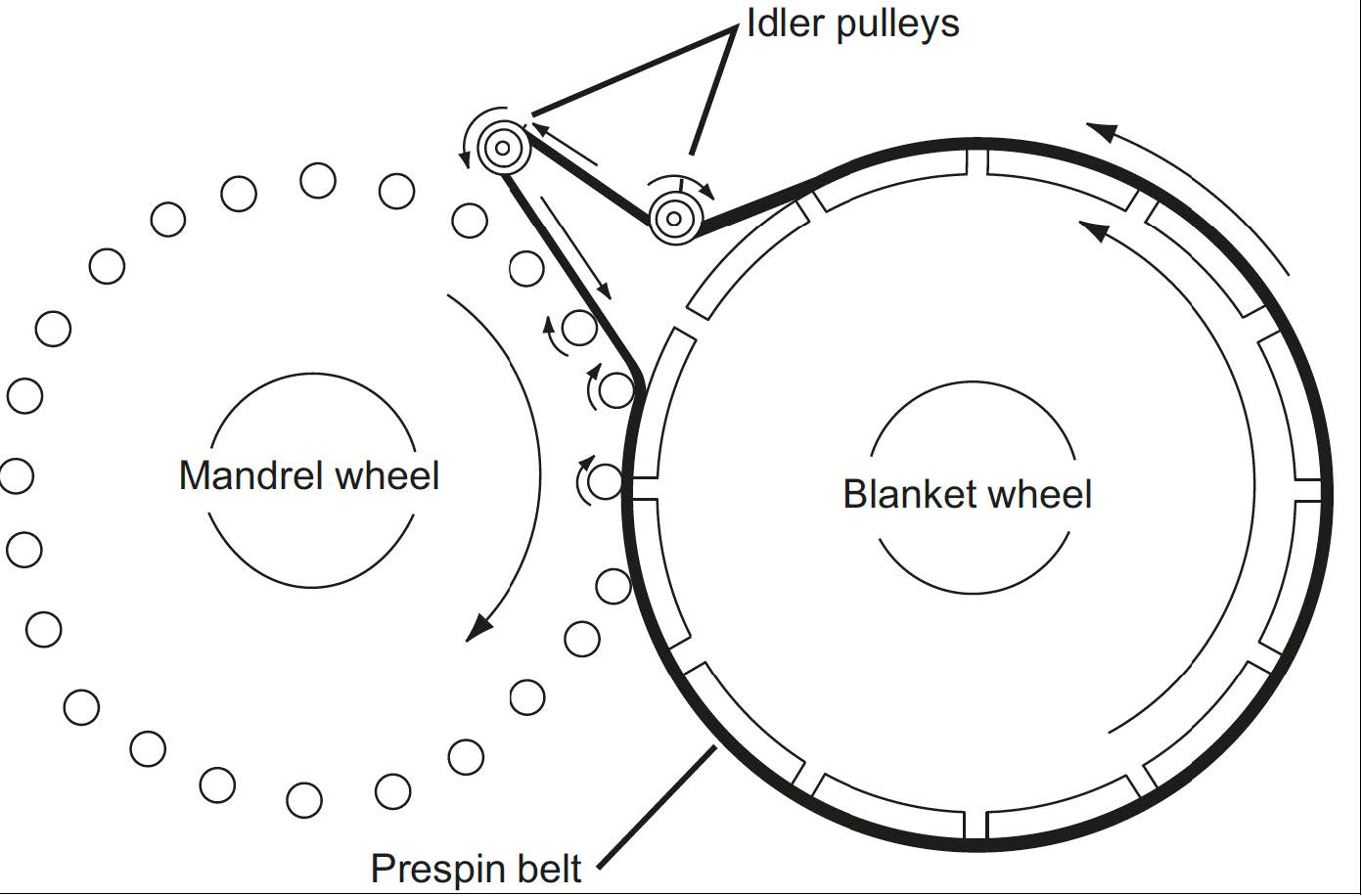

The mandrel travel is further guided by the mandrel cam, strategically located behind the mandrel wheel. This cam provides a meticulously designed path for the mandrels to travel along as the wheel rotates. Each mandrel station is equipped with dual cam followers, meticulously designed to follow the contours of the cam, ensuring precise alignment with other printing assemblies. This precision alignment is crucial for consistent and accurate printing on cans, even when the printing process continues at high speed.

Accompanying the mandrel cam is the blanket wheel, a key part of the ink transfer process. Located next to the mandrel wheel, the blanket wheel houses a series of segments, each adorned with replaceable blankets. As the blanket wheel rotates counterclockwise, the blankets contact the cans on the mandrel wheel, transferring the desired label or design with maximum precision. This intricate dance between the mandrel and blanket wheels is facilitated by Mastercam’s advanced path generation, ensuring that every print is executed to perfection.

Mastercam’s role goes beyond precise printing to optimize production workflows and ensure quality. Mastercam integration automates repetitive tasks, streamlining the printing process and minimizing the risk of errors. In addition, comprehensive quality control and traceability tools provide operators with real-time information on the printing process, ensuring that each can meets the stringent quality standards expected in the industry.

Meticulous adjustments and maintenance procedures are essential for the perfect operation of Stolle printing machines. From the fine adjustment of the sensor to the correct alignment of the mandrel cam and blanket wheel, every detail is meticulously calibrated to perfection. Mastercam Mastercam integration not only improves accuracy, but also simplifies the fitting process. the adjustment process, providing operators with intuitive tools for printing parameters according to specific needs.

In conclusion, the integration of Mastercam on Stolle presses heralds a new era of precision and efficiency in can decoration. By seamlessly combining advanced technology with meticulous engineering, Stolle sets new standards for quality and innovation in the industry. With Mastercam as a guiding force, Stolle printing machines are poised to revolutionize the can decorating process. revolutionize the can decoration process, offering impeccable results.

with unprecedented accuracy and efficiency.

EXPLORING THE COMPLEXITIES OF MASTERCAM INTEGRATION:

Beyond the core components and functionalities, delving into the intricacies of Mastercam integration reveals a tapestry of nuances. In the complexities of Mastercam’s integration reveals a tapestry of shading

and optimizations that elevate can decoration to an art form.

PRECISION ADJUSTMENT WITH MANDREL ADJUSTMENT CAMS:

The mandrel cam, although seemingly simple in function, undergoes meticulous adjustments to ensure optimum performance. During Decorator, the position of the mandrel cam is carefully checked and adjusted. It is carefully checked and adjusted. This crucial step is essential to align the mandrels with the blanket segments, ensuring that the printing process is carried out with maximum precision.

In addition, continuous adjustments may be necessary if discrepancies arise between the mandrel and the blanket segment. Even a minor difference of 0.002 inches can affect print quality, underscoring the need for accurate calibration. of an accurate calibration. The integration of Mastercam simplifies this adjustment process by providing operators with intuitive tools to maintain optimal alignment of the mandrel cam and blanket segments.

MAXIMIZING EFFICIENCY BY OPTIMIZING THE BLANKET WHEEL

The blanket wheel, with its intricate system of segments and replaceable blankets, is the cornerstone of the ink transfer process. Replaceable, it is the cornerstone of the ink transfer process. However, for optimum performance it requires meticulous adjustments and fine tuning. Critical adjustments include synchronization with the chuck wheel, adjusting the pressure and ensuring correct alignment of the toe position.

The integration of Mastercam streamlines these adjustment procedures, providing operators with intuitive interfaces to print. By simplifying these processes, Mastercam improves Mastercam improves efficiency and minimizes downtime, allowing operators to focus on high-quality printing without the hassle of complex adjustments.

PRECISION PRINTING WITH ADVANCED TOOLPATH GENERATION:

Mastercam’s advanced path generation capabilities play a key role in achieving precision printing on complex can geometries. Whether it’s intricate designs or precise text, Mastercam ensures that every detail is faithfully reproduced on the surface of the can. Detail is faithfully reproduced on the surface of the can.

In addition, Mastercam’s machining strategies optimize tool wear by minimizing tool wear and maximizing efficiency. By generating Mastercam, it minimizes production times while maintaining superior print quality. Maintaining superior print quality, enabling Stolle printing presses to meet demanding industry requirements with ease.

SETTING NEW STANDARDS OF QUALITY AND INNOVATION:

In the competitive landscape of can decoration, the integration of Mastercam into Stolle Machinery sets new standards for quality and innovation. De Stolle Machinery sets new standards for quality and innovation. Leveraging state-of-the-art technology and precision engineering, Stolle printing presses deliver flawless results with unmatched efficiency. With Mastercam as a guiding force, Stolle continues to push the boundaries of what is possible in the printing industry. the limits of what is possible in the decoration of cans. From intricate designs to precise printing, Mastercam integration ensures that Stolle Stolle printing machines remain at the forefront of the industry, setting new benchmarks and redefining the art of can decoration.