For more than six decades, Imeta has been at the forefront of can seamer innovation. Their dedication to improving and upgrading these machines ensures that they remain state-of-the-art. Remarkably, many models from the last century are still in good condition, demonstrating exceptional engineering that rivals modern technology.

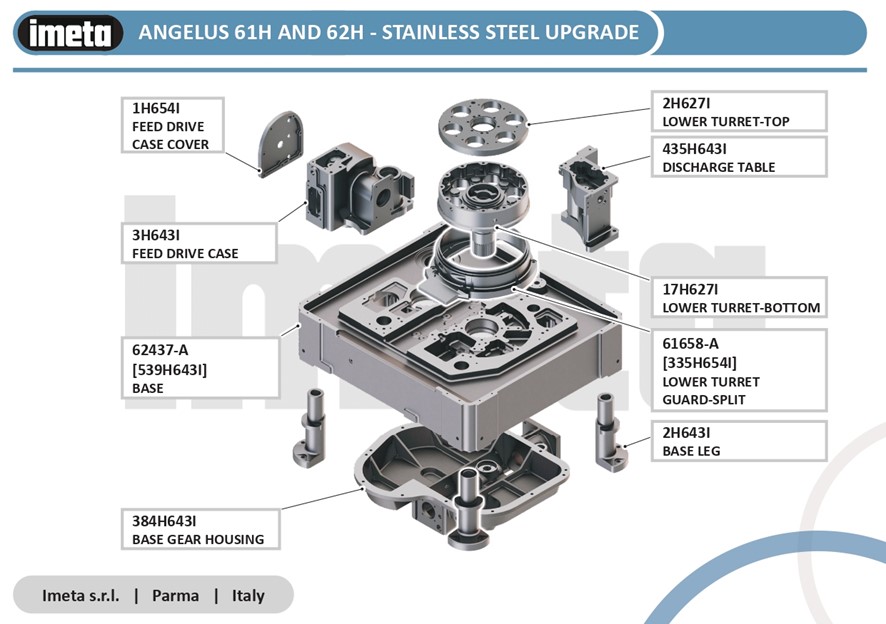

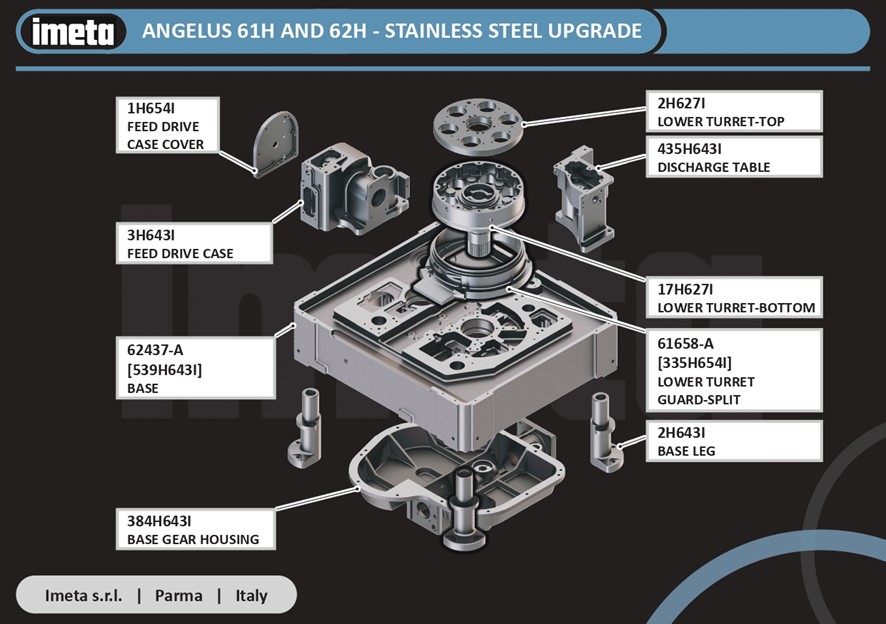

The rigidity and stability of iron castings are incomparable compared to today’s welded frames. However, the main disadvantage of cast iron is its susceptibility to corrosion and the difficulties it presents for sanitization. To address these challenges, Imeta now offers stainless steel bases and structural parts as replacements for the original cast iron components.

This significant advancement allows renowned seamers such as the Angelus 60L, 61H, 62H, 80L, 81L, 120L, 121L and others to meet stringent sanitizing standards while maintaining the rigidity and robustness that have defined their historical excellence in can seaming.

IMETA’s manager, Roberto Baroni, says that, since the beginning of his experience in the world of canning, he has always been amazed at how old and rusty machines were used to seal tinplate cans. “The truth is that, were it not for corrosion caused by food products and moisture in factories, with proper maintenance, can sealers are machines capable of running for dozens of years.”