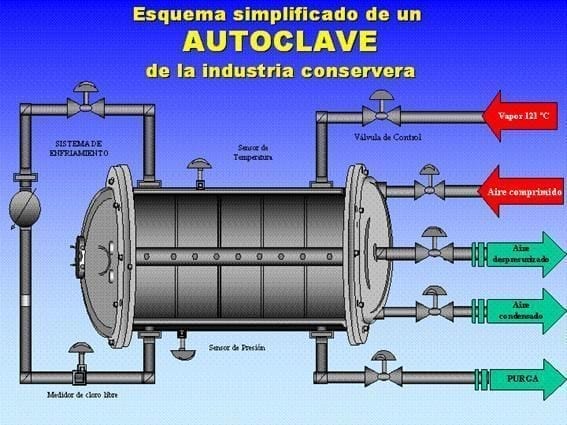

Cooling of canned tuna containers in the autoclave should be done using chlorinated water with a free chlorine residual of 0.5 to 2.0 ppm after contact with the containers. It is important to carry out a strict control of this chlorine concentration for each batch of canned tuna sterilized. Cooling should be very rapid, reaching 40°C or less in the center of the container in less than 10 minutes, depending on the size of the container. This procedure is crucial to prevent spores of thermophilic microorganisms that have survived the sterilization process from mutating into viable cells that will alter the packaged product. In addition, proper cooling helps to prevent cans from becoming moist and at risk of oxidation.

To avoid deformation of the containers during cooling in the autoclave, the use of chlorinated potable water at a pressure of 10 – 12 lb/in^2 with compressed air is recommended. The final cooling temperature should be less than 35°C, and it is important to handle the containers carefully after cooling to protect the integrity of the sealed and thermally processed container.